Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

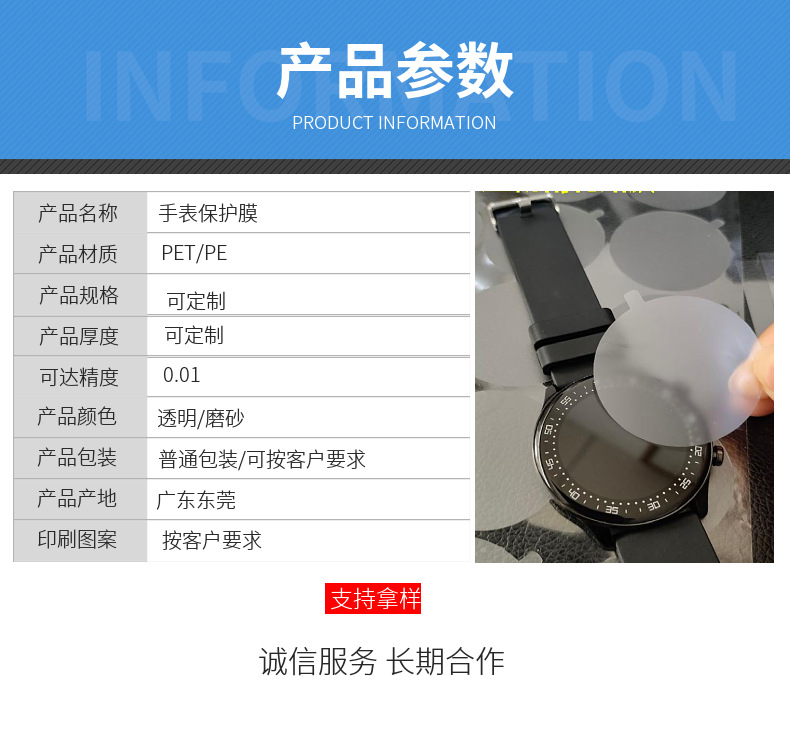

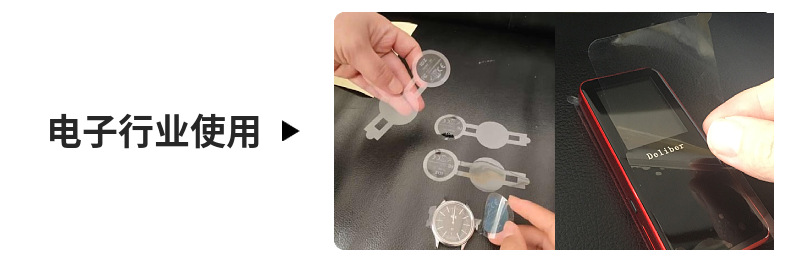

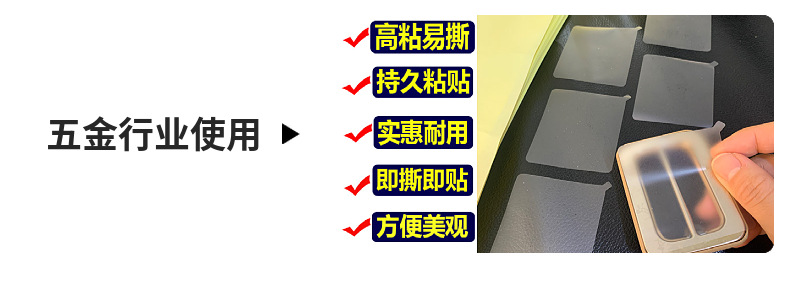

| pet transparent protective film | CN¥ 0.0 |

| pet frosted frosted protective film | CN¥ 0.0 |

| pet blue protective film | CN¥ 0.0 |

| pe transparent protective film | CN¥ 0.0 |

| pe blue protective film | CN¥ 0.0 |

| pet transparent roll protective film | CN¥ 0.0 |

| pet color roll protective film | CN¥ 0.0 |

Miaotian adhesive tape factory 5yr.

Contacts:jianchen Chat

Mobile:86-15988599892

E-mail:1376878055@qq.com

The production process of the watch protection film generally includes the following steps:

1. Material preparation: Choose materials with sufficient transparency, good scratch resistance, anti-pollution, and water resistance performance. Commonly used materials include PET, PP, PE, PVC, etc.

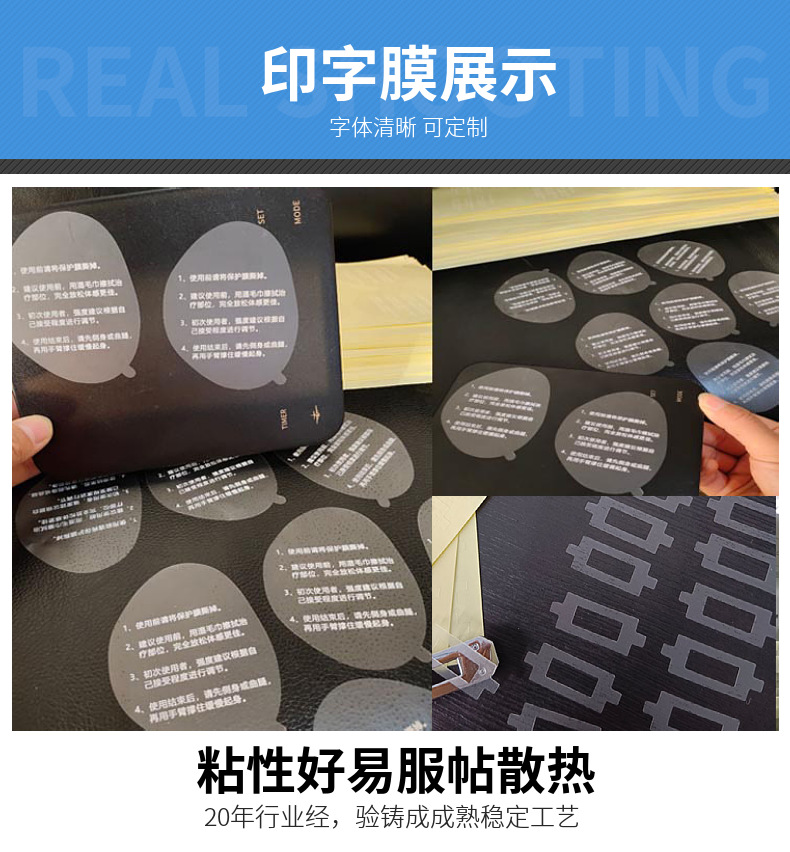

2. Printing: Based on customer requirements, some patterns, logos, and other content are printed, generally using screen printing or flexographic printing.

3. Coating: Apply a special glue to the surface of the material to protect the watch from scratches, wear and other damage.

4. Cutting: After coating, the material is cut and processed into different shaped protective films according to customer requirements.

5. Final Inspection: Inspect the cut-out watch protective films to ensure there are no bubbles or defects, and that the dimensions and shapes meet the customer's requirements.

For watch protective films for flat and raised surfaces, different materials have their own advantages and disadvantages, and the correct choice should be determined based on specific needs.

For flat watches, PET material has good transparency, hardness, and scratch resistance, making it more transparent than other materials. However, for curved surfaces, PET material is not easy to deform, and there may be bubbles after adhesive application.

For convex and concave watch faces, it is best to use PE or PVC materials, as their flexibility is better, which can ensure that the flexible curved surface can be completely and accurately covered, preventing the occurrence of cracks, bubbles, or peeling at the edges.

Certainly, the final choice should be determined based on actual needs, and multiple material tests can be conducted, combined with the cost, environmental friendliness, and production efficiency of the materials.Can provide a variety of materials. Design a variety of test schemes.

013

Update time:

TOP