Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| transparent-round | CN¥ 0.03 |

| transparent-oval | CN¥ 0.03 |

| transparent-square | CN¥ 0.03 |

| frosted-round | CN¥ 0.03 |

| frosted-square | CN¥ 0.03 |

| blue-round | CN¥ 0.03 |

| transparent-printed logo | CN¥ 0.03 |

| mesh | CN¥ 0.03 |

Miaotian adhesive tape factory 5yr.

Contacts:jianchen Chat

Mobile:86-15988599892

E-mail:1376878055@qq.com

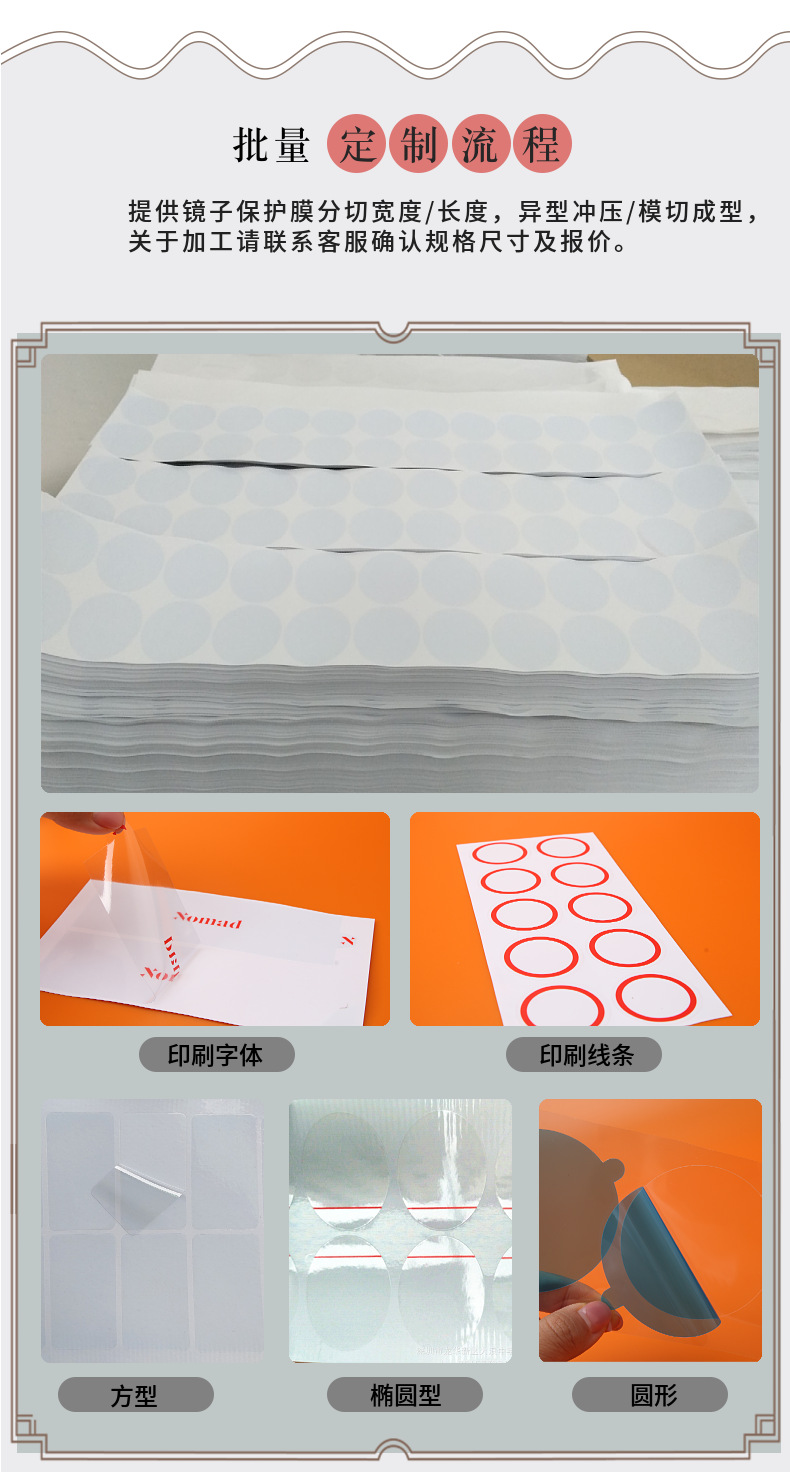

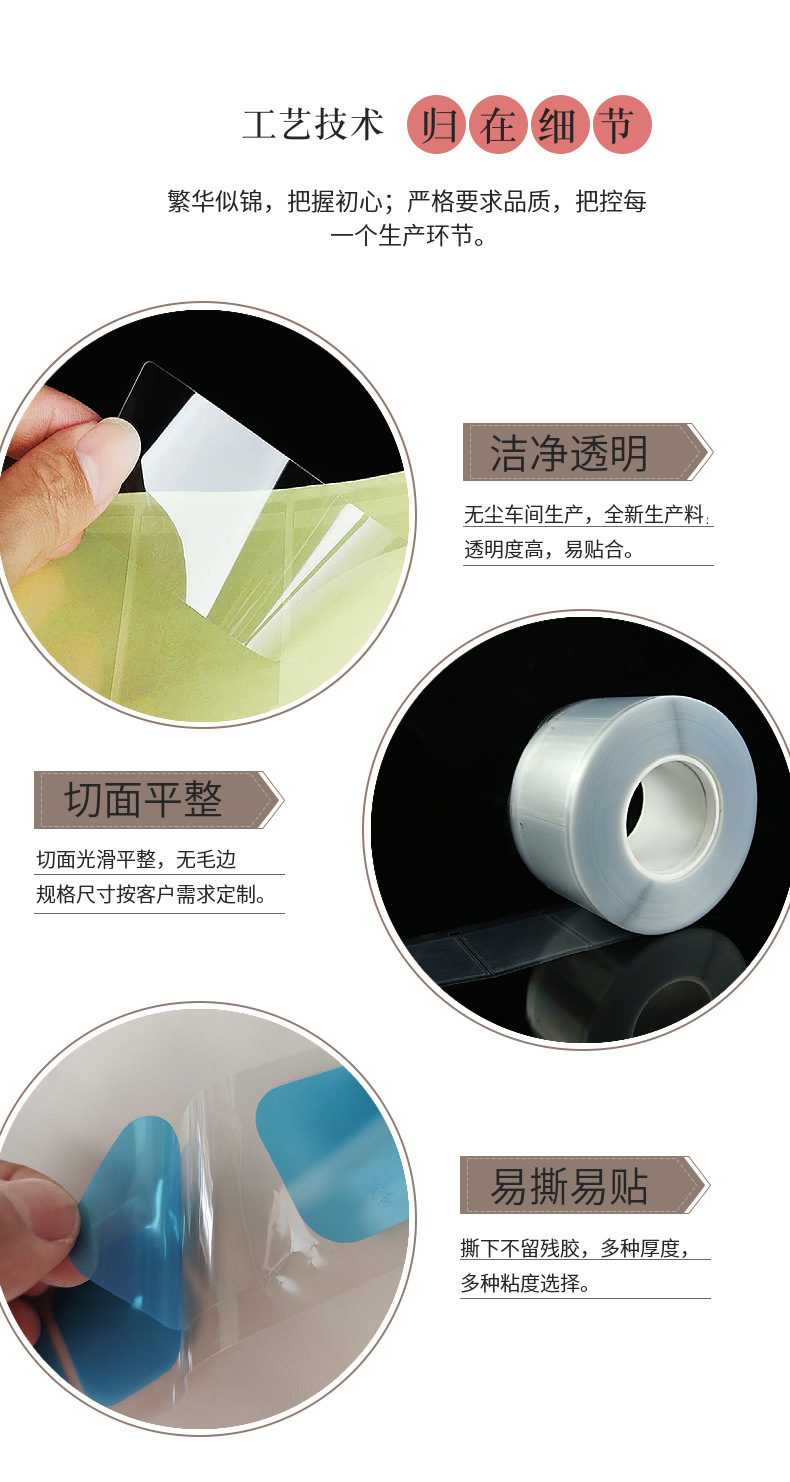

Production Process

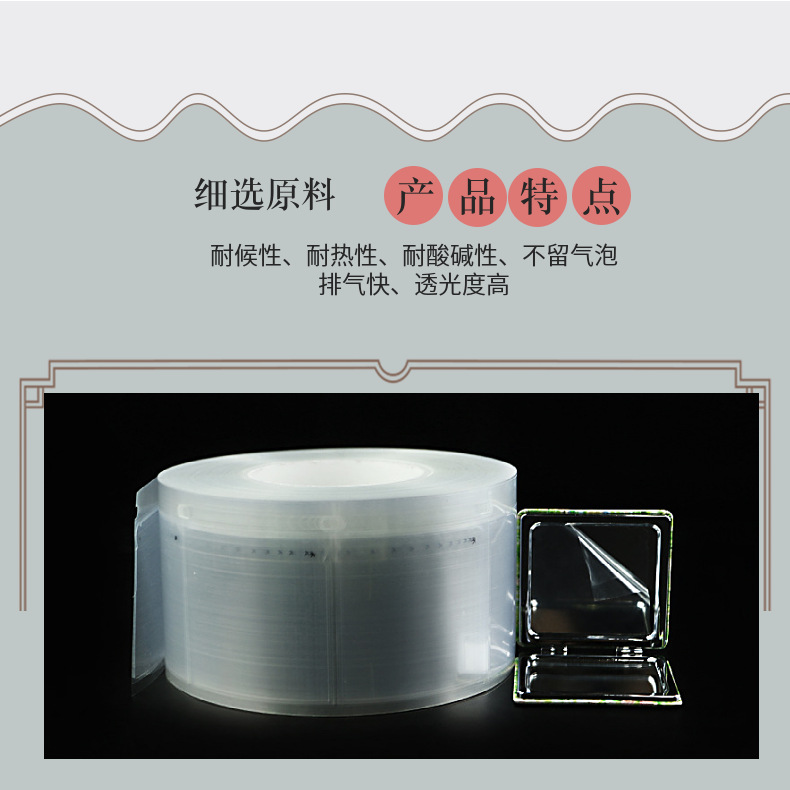

1. The production process of PE static film makeup mirror protection film:

The PE (polyethylene) particles are made into a film, and then the film is attached to the surface of the makeup mirror using the electrostatic adhesion technology. This process is simple and low-cost, but the protection effect is limited.

2. The production process of PET makeup case protection film:

PET (Polyethylene terephthalate) film is widely used in electronic products, food packaging and other fields. In the production process of PET protective film, PET grains are first discharged into film by using a twin-roll extruder, and then the film is processed further according to different needs, such as die-cutting and lamination.

3. The production process of the sandblasted anti-scratch film:

This film is a special type of PET material, and the production process includes: powder preparation → extrusion → drawing → coating → attachment → cutting → output, etc.

4. The production process of PVC protective film:

PVC protection film can be produced by a variety of processes such as extrusion, injection molding, and blow molding. The most commonly used process is extrusion, which generally includes: mixing the raw materials, melting and extruding, molding, cooling, and cutting the product.

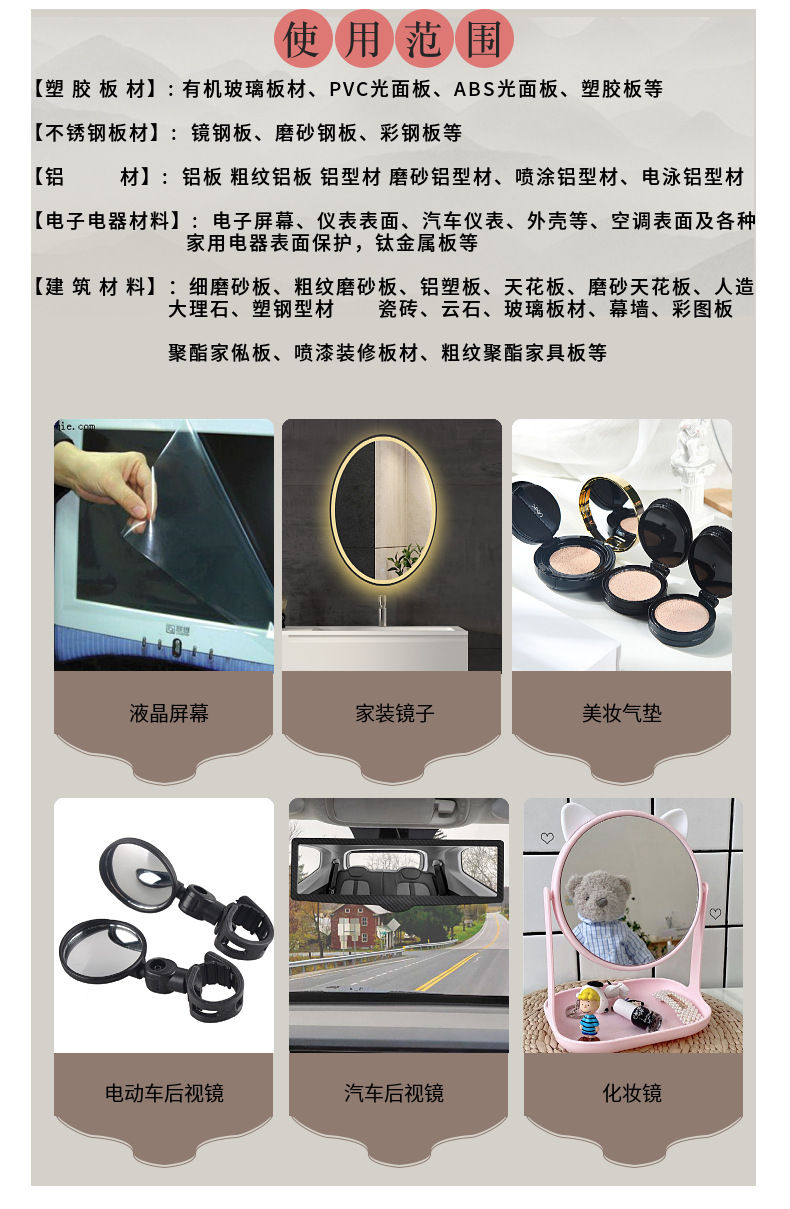

Application Selection:

1. PE static-electrical film makeup mirror protection film:

Suitable for makeup mirrors, glass display cabinets, etc., where anti-scratch and wear resistance are not required.

2. PET Cosmetic Case Protection Film:

Suitable for the surface of makeup boxes, foundation surfaces, and electronic products, which need anti-scratch and anti-explosion. It can also be used in fields such as cosmetic packaging.

3. Sandblasting anti-scratch film:

Suitable for various makeup boxes, plastic shells. Metal surfaces such as metal. Places that need anti-scratch and wear-resistant.

4. PVC Protection Film:

Suitable for various household appliances, electronic products, automotive interiors, etc. It has good mechanical properties and features such as water resistance and wear resistance. 013

Update time:

TOP