Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

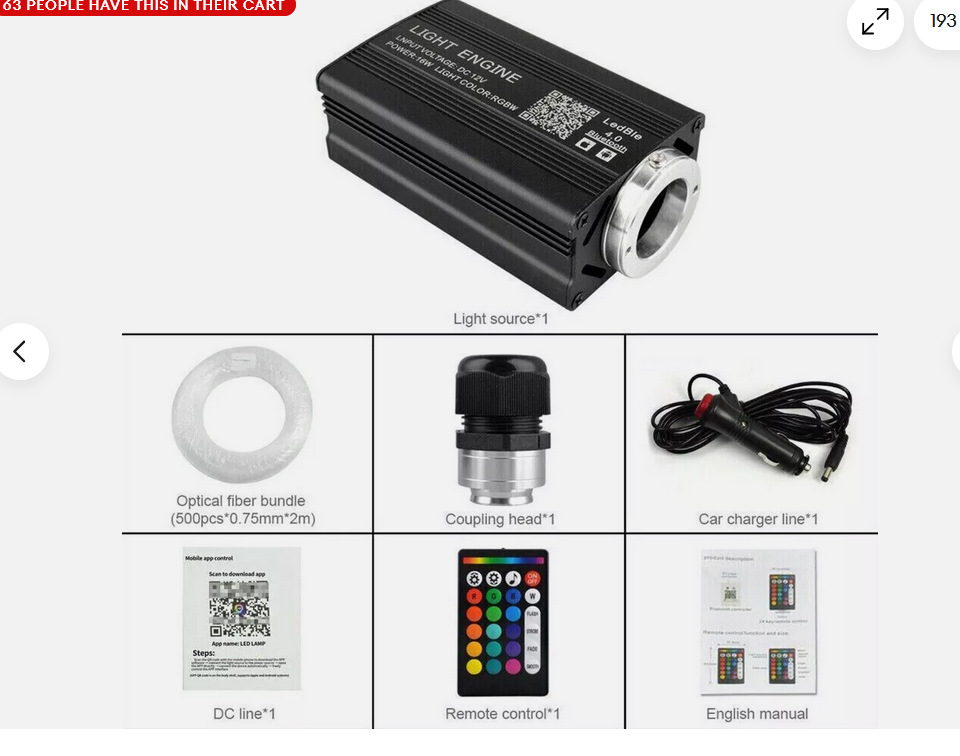

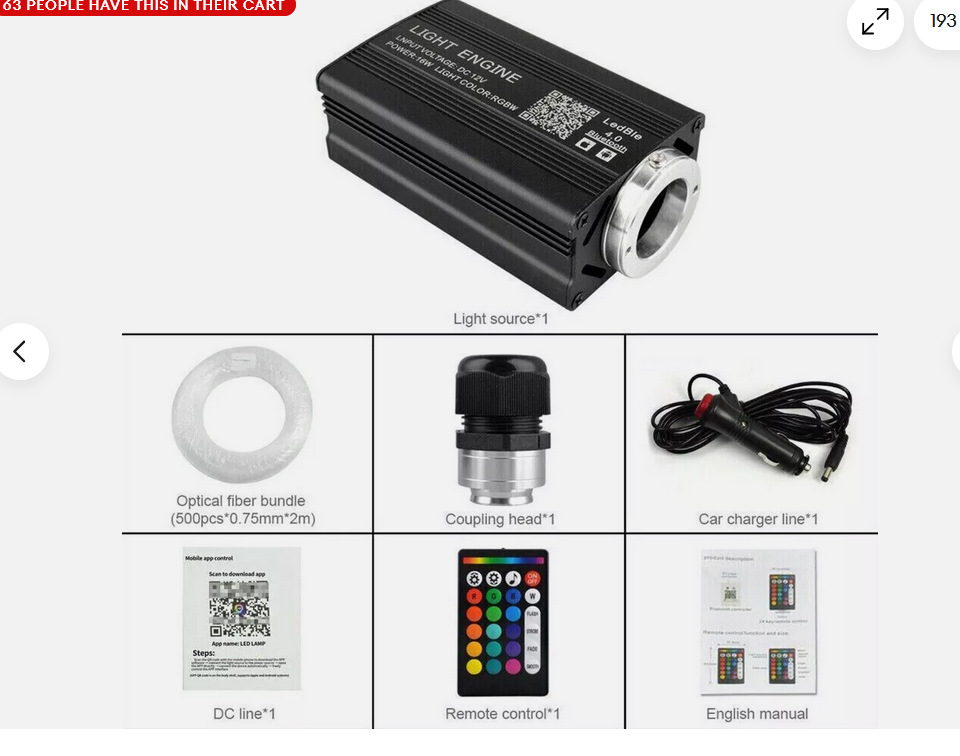

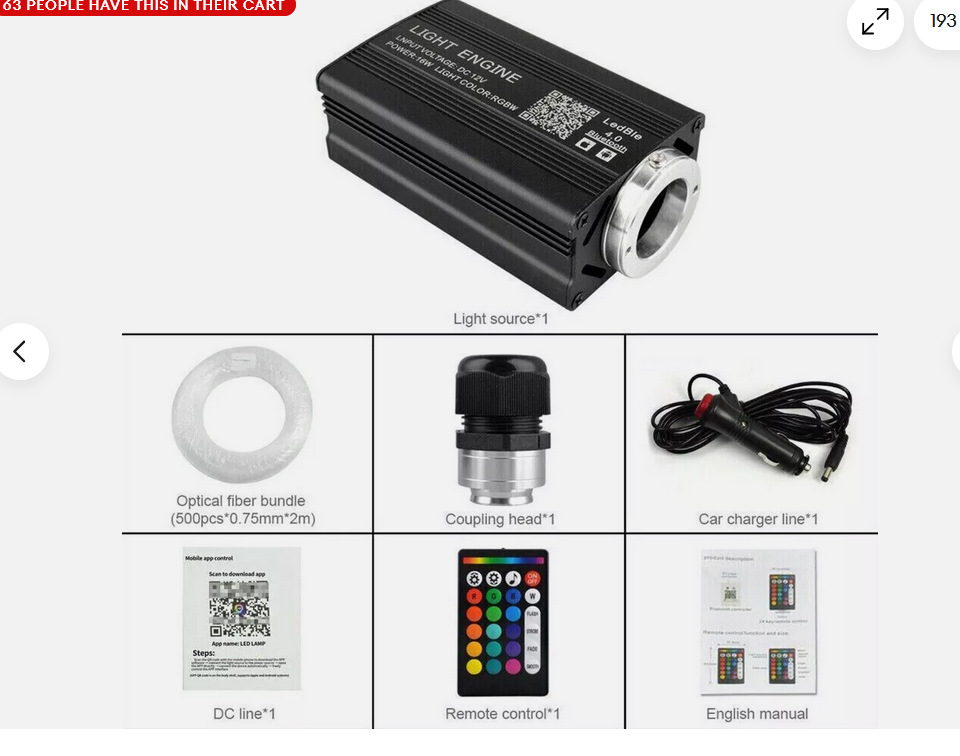

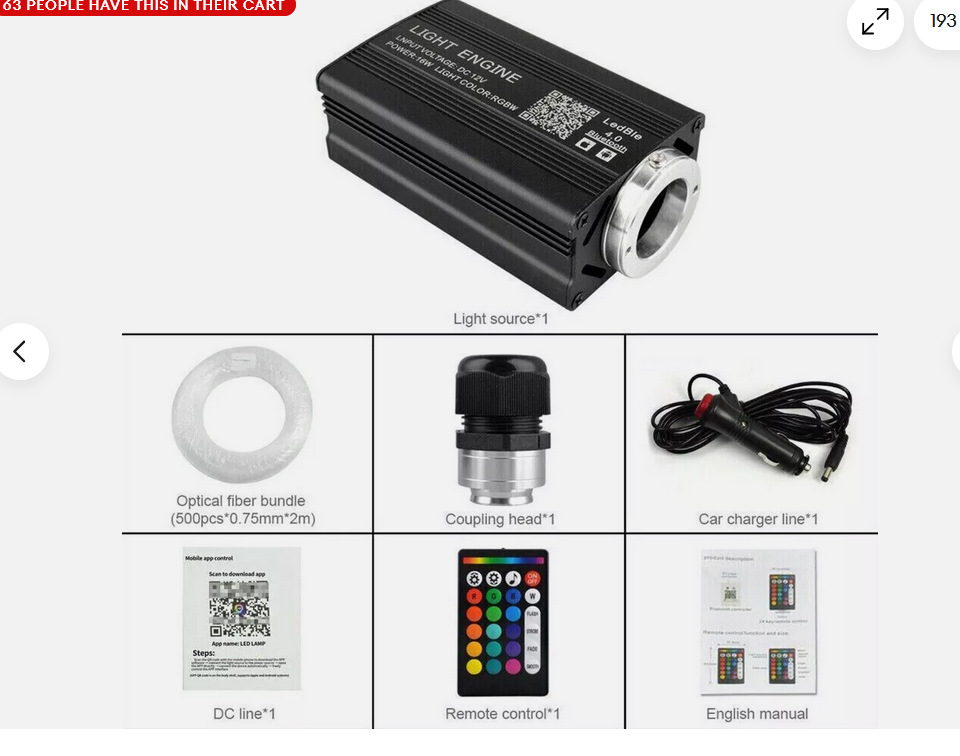

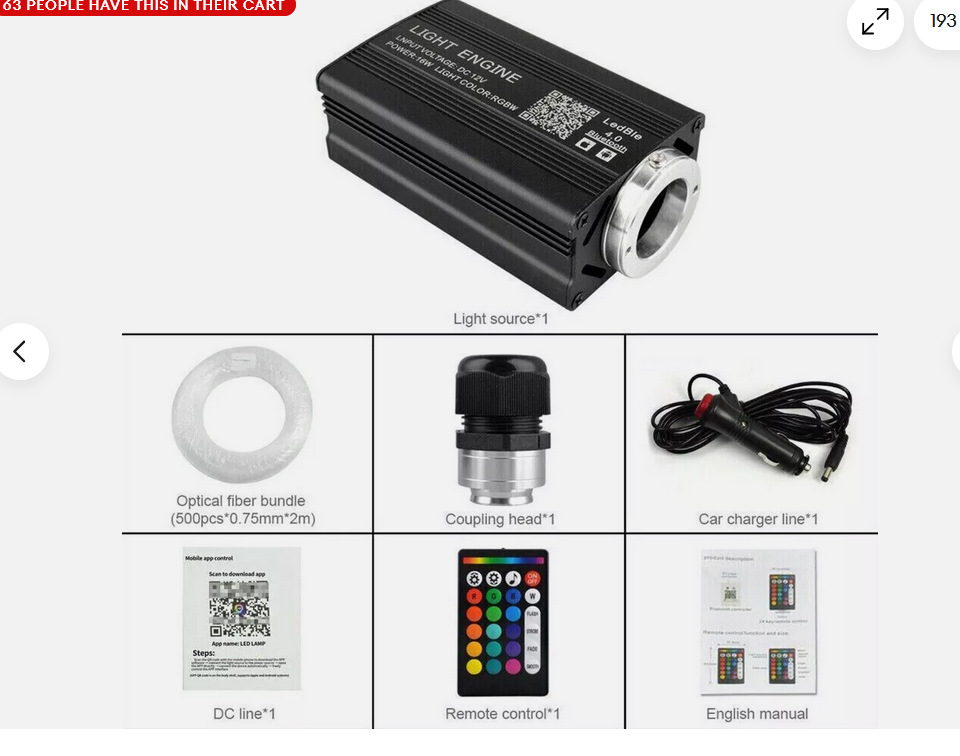

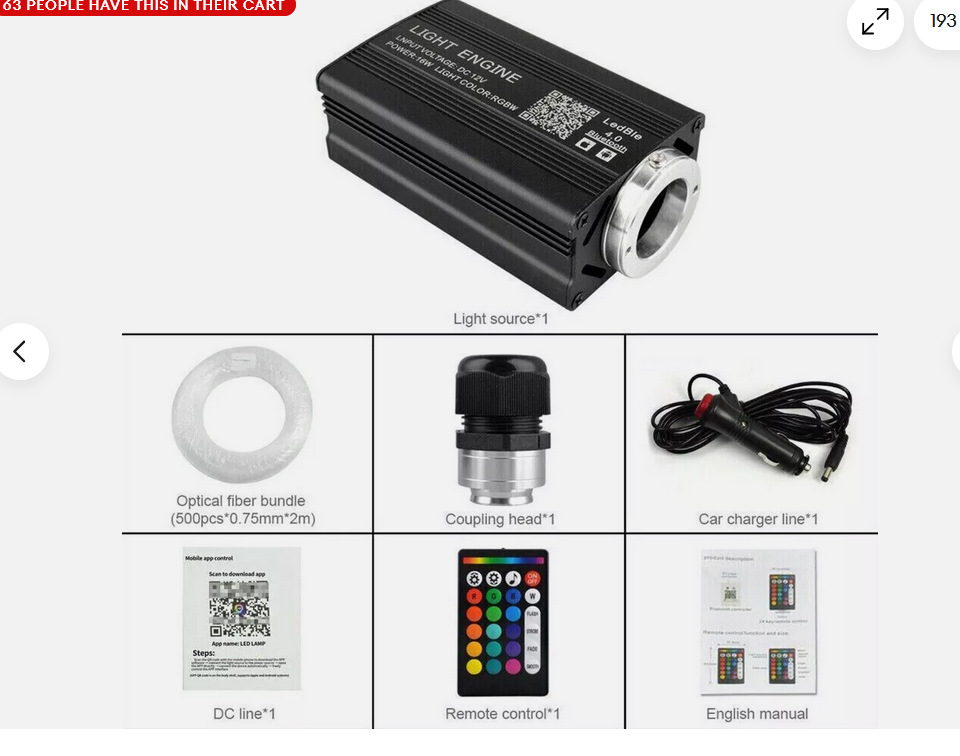

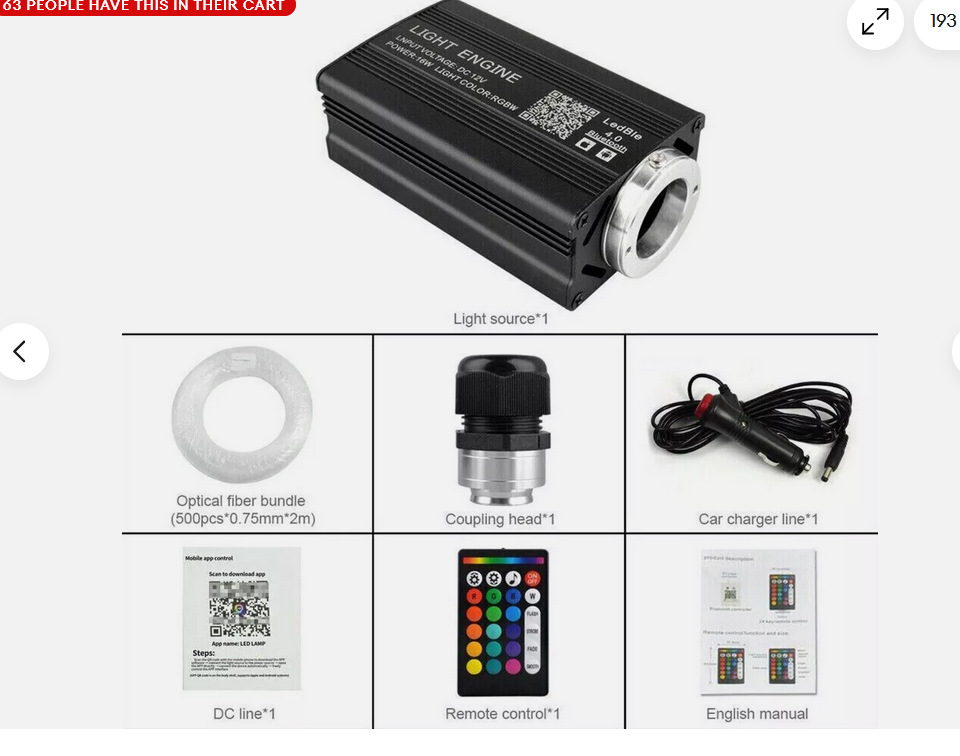

12vrgbw light source machine (dc cable) app + remote control

12vrgbw light source machine (dc cable) app + remote control

|

CN¥ 104.5 |

12vrgbw (dc cable) 0.75mm300 pieces 2 m

12vrgbw (dc cable) 0.75mm300 pieces 2 m

|

CN¥ 147.25 |

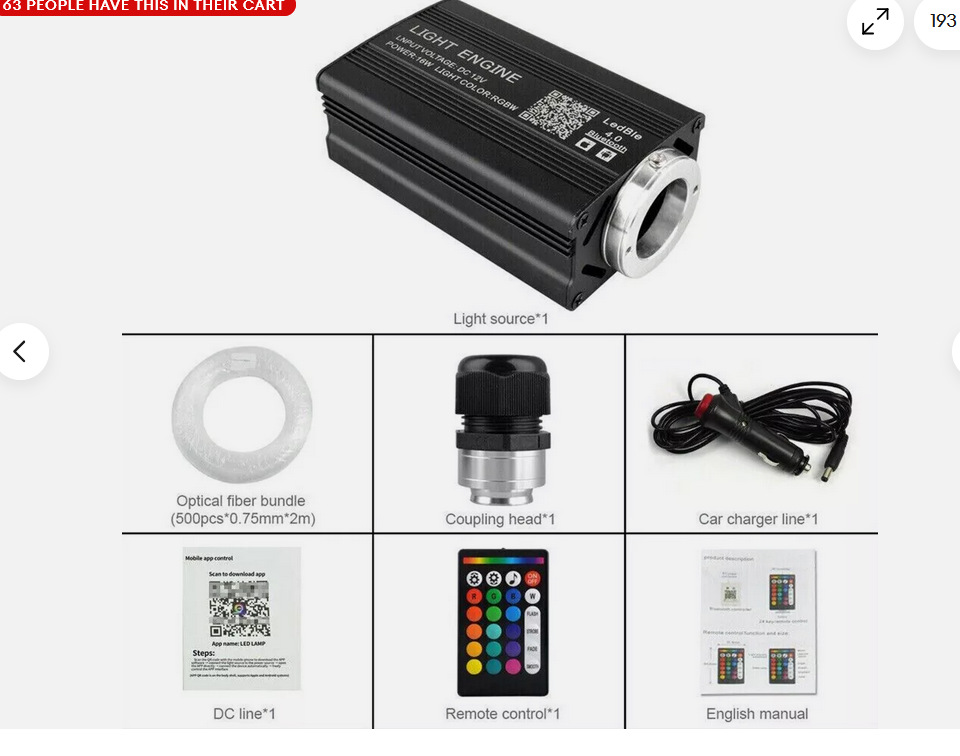

12vrgbw light source machine (dc cable) 0.75mm optical fiber 500 2 m

12vrgbw light source machine (dc cable) 0.75mm optical fiber 500 2 m

|

CN¥ 161.5 |

12vrgbw light source machine (dc cable) 0.5mm optical fiber 1000 2 m

12vrgbw light source machine (dc cable) 0.5mm optical fiber 1000 2 m

|

CN¥ 171.0 |

12vrgbw light source machine (dc cable) 0.75mm optical fiber 450 3 m

12vrgbw light source machine (dc cable) 0.75mm optical fiber 450 3 m

|

CN¥ 175.75 |

12vrgbw light source machine (dc cable) 0.75mm optical fiber 500 3 m

12vrgbw light source machine (dc cable) 0.75mm optical fiber 500 3 m

|

CN¥ 183.35 |

12vrgbw light source machine (dc cable) 0.75mm optical fiber 480+20 1mm(3 m)

12vrgbw light source machine (dc cable) 0.75mm optical fiber 480+20 1mm(3 m)

|

CN¥ 190.0 |

12vrgbw light source machine (dc cable) 0.75mm optical fiber 550 3 m

12vrgbw light source machine (dc cable) 0.75mm optical fiber 550 3 m

|

CN¥ 192.85 |

12vrgbw light source machine (with car cigarette lighter) +0.75mm300 pieces 2 m

12vrgbw light source machine (with car cigarette lighter) +0.75mm300 pieces 2 m

|

CN¥ 152.0 |

12vrgbw light source machine (with car cigarette lighter) +0.75mm500 2 m

12vrgbw light source machine (with car cigarette lighter) +0.75mm500 2 m

|

CN¥ 166.25 |

12vrgbw light source machine (with car cigarette lighter) +0.5mm1000 pieces 2 m

12vrgbw light source machine (with car cigarette lighter) +0.5mm1000 pieces 2 m

|

CN¥ 175.75 |

12vrgbw light source machine (with car cigarette lighter) 0.75mm optical fiber 450 3 m

12vrgbw light source machine (with car cigarette lighter) 0.75mm optical fiber 450 3 m

|

CN¥ 180.5 |

12vrgbw light source machine (with car cigarette lighter) 0.75mm optical fiber 500 3 m

12vrgbw light source machine (with car cigarette lighter) 0.75mm optical fiber 500 3 m

|

CN¥ 188.1 |

12vrgbw (vehicle cigarette lighter) 0.75mm optical fiber 480+20 1mm(3 m}

12vrgbw (vehicle cigarette lighter) 0.75mm optical fiber 480+20 1mm(3 m}

|

CN¥ 194.75 |

12vrgbw light source machine (vehicle cigarette lighter) 0.75mm optical fiber 550 3 m

12vrgbw light source machine (vehicle cigarette lighter) 0.75mm optical fiber 550 3 m

|

CN¥ 197.6 |

light source machine (cigarette lighter +220v power adapter) +0.75mm300 2 m

light source machine (cigarette lighter +220v power adapter) +0.75mm300 2 m

|

CN¥ 161.5 |

light source machine (cigarette lighter +220v power adapter) 0.75mm optical fiber 500 2 m

light source machine (cigarette lighter +220v power adapter) 0.75mm optical fiber 500 2 m

|

CN¥ 175.75 |

light source machine (cigarette lighter +220v power adapter) 0.5mm optical fiber 1000 2 m

light source machine (cigarette lighter +220v power adapter) 0.5mm optical fiber 1000 2 m

|

CN¥ 185.25 |

light source machine (cigarette lighter +220v power adapter) 0.75mm optical fiber 450 3 m

light source machine (cigarette lighter +220v power adapter) 0.75mm optical fiber 450 3 m

|

CN¥ 190.0 |

light source machine (cigarette lighter +220v power adapter) 0.75mm optical fiber 500 3 m

light source machine (cigarette lighter +220v power adapter) 0.75mm optical fiber 500 3 m

|

CN¥ 197.6 |

light source machine (cigarette lighter + adapter) 0.75mm optical fiber 480+1mm20 3 m

light source machine (cigarette lighter + adapter) 0.75mm optical fiber 480+1mm20 3 m

|

CN¥ 204.25 |

light source machine (cigarette lighter +220v power adapter) 0.75mm optical fiber 550 3 m

light source machine (cigarette lighter +220v power adapter) 0.75mm optical fiber 550 3 m

|

CN¥ 207.1 |

220v power adapter default (american standard) other specifications contact customer service remarks

220v power adapter default (american standard) other specifications contact customer service remarks

|

CN¥ 104.5 |

Yiwu GALAXY Lighting CO.,Ltd 11yr.

Contacts:rouse Chat

Mobile:86-17357934268

E-mail:yuki@galalamp.com

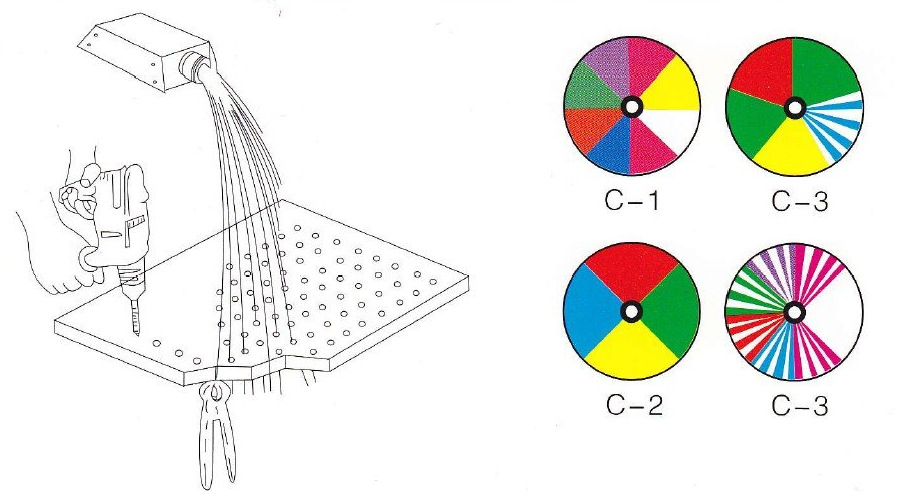

Fiber optic lamp manufacturing process as follows:

1. Light Install

General light emitting devices should be placed in locations that are convenient for operation, easy to maintain, and not easily accessible to outsiders. Indoor type light emitters can be directly installed on special supports in the electrical shaft, or they can be placed in locked distribution boxes, mounted on the wall or embedded in the wall. Outdoor type light emitters can be directly installed on outdoor special supports, or they can be placed in locked outdoor rainproof boxes, mounted on the wall or on angle steel supports. The metal protective shell and metal installation accessories of the system should be electrically connected reliably with the roof's lightning protection device. When installing, it should also be equipped with a reliable power outlet according to the actual situation of the site.

2. Fiber Optic Installation

The laying of light-emitting fiber optic cables is similar to that of general cables, and can be installed in PVC plastic pipes or along plastic troughs. The length should be as straight as possible to reduce bending, to prevent light loss due to bending. If there are bends, the radius of the bend should be greater than or equal to 12 times the diameter of the fiber optic cable.

Line light fiber optic cables are generally installed on the surface of billboards, building exteriors, or interior walls of buildings. They can be fixed using clip fasteners or binding straps. When bending, the radius of the bend should be greater than or equal to 20 times the diameter of the fiber optic cable. When entering or exiting the building surface, water-proofing measures should be taken.

3. Connecting the point light fiber with the light emitting terminal accessory

Generally, a dedicated connector kit is used to connect the point light fiber to the light emitting terminal accessory. To ensure a bright output of the system, it is necessary to ensure that the interface ports of the light emitting terminal accessory are clean, the cut end of the point light fiber is straight and clean, and the entire connection process should have dustproof measures.

4. Installation of Light Emitting Terminal Accessories

The installation of fiber-optic lighting is essentially the same as that of conventional lighting, and thus it is not necessary to elaborate on it here. In conclusion, the advantages of fiber-optic lighting are obvious, but it is also quite expensive. We believe that as science and technology develop and the production of fiber-optic lighting products becomes more mass-produced, the cost will inevitably fall to an acceptable range, making fiber-optic lighting products more widely applicable in various fields. The unique dynamic lighting effects and physical characteristics of fiber-optic lighting will make architectural lighting even more vibrant and colorful.

Section Two: Introduction to Fiber Optic Lamps

Fiber optic lights are made with special high-performance transparent flame-retardant engineering plastics as the outer shell, ensuring that they will not fracture or deform over a long period of time, with a lifespan of at least 10 years. Due to the use of high-purity core materials, the attenuation of light transmission is effectively reduced, achieving efficient light transmission. They are easy to install due to their high purity, low attenuation, and reliability. They are safe, environmentally friendly, flexible, complete, and can produce a colorful, dream-like visual effect. They do not emit ultraviolet rays, produce low heat, and are safe to use, with a long service life, a rich color palette, good durability, and plasticity. Therefore, they are considered an ideal material to replace current decorative lighting methods.

Update time:

TOP