Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

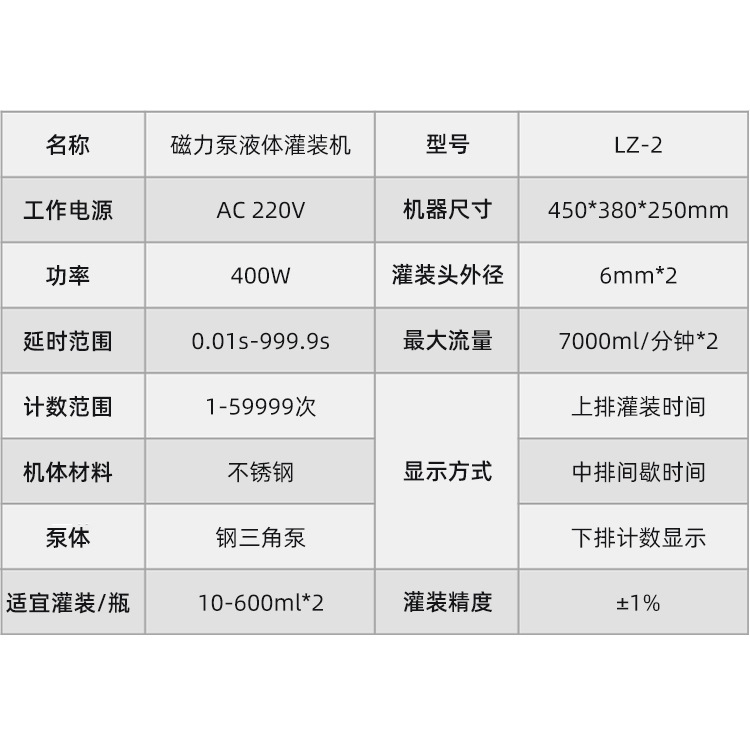

| lz-2 | CN¥ 0.0 |

Haining Dingdu Automation Equipment Co., Ltd. 2yr.

Contacts:Yang Bochao Chat

Mobile:86-13588876188

E-mail:13588876188@qq.com

Default order with a handle switch.

If you need a foot pedal switch, please contact customer service to note, and replace the handle switch with a foot pedal switch!

===================

Our standard configuration is a 40-liter heating container, which heats up quite slowly. If you have a large production volume, we recommend that you configure a larger heating container and purchase a separate filling machine (contact customer service).

Separate filling machine link: https://detail.1688.com/offer/670175072671.html?spm=a26286.8251493.description.2.221425b2Lm7blO

===================

This machine is a specialized machine for filling crystal candle, butter tea wax, and other oil-based materials. It has forward and reverse wax return functions, a large power, and is not easily clogged. If it does clog, it is also easy to clean.

This machine uses a micro-motor self-suction cycloid pump head and is controlled by a microcomputer to set the working and interval times of the pump, enabling automatic and quantitative filling. It is suitable for filling 10ml or more oily liquids, such as candle wax, shortening, crystal candles, cooking oil, and salad oil.

If you need to fill candles, melt them into liquid in the accompanying heating bucket, and then follow our instructions for easy filling. The trolley is mobile for filling.

Instructions: Prepare the liquid to be filled. Connect the 220V power supply, adjust the filling time and the interval time, set the timer. First, press the point-and-click switch to test the machine. If the motor operates normally, press the manual button and use the foot switch to control the filler. Press once to operate the filler once. Press the automatic button, and the filler will automatically and continuously operate according to the set time.

Steps

1. Time Adjustment for Filling

A, press the setting key first, and the time will flash. Then press the increase key 0-9 to set the time for that position.

Press B, then press the right shift key to the specified position, press the increase key to adjust the time for that position, and repeat the operation.

Press the unit key to move the decimal point up and down, and set the time unit

Press the exit key to complete the setup.

2. Adjustment of Intermission Time: The same as the adjustment of filling time.

3. Timer Adjustment

Press the setting button, and the timer will blink. Press the increase button 0-9 to adjust the quantity of the corresponding position, and press the right shift button to adjust the quantity of other positions. Set the required quantity.

Press the pattern key, when the light is on, the filling machine stops working when the specified quantity is reached. If the light is off, it will continue to work and count continuously.

4. Filling Setting Press the filling setting to start the filling machine. When the filling reaches the desired amount, press the filling setting key again. The time displayed on the filling time is the time required to fill the amount.

The feature of this machine is

1.. The function of filling setting can quickly set the required time for the desired filling amount

2. Panel CNC display, simple and clear operation

3. This machine uses a steel pump head that is resistant to high temperatures, suitable for filling butter and candle products.

4. The pump head is easy to disassemble and clean, with strong power, and is not afraid of clogging.

5. Heat the wax in the heating container, adjust the temperature by the knob, range from 30 to 110°C

Update time:

TOP