Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Haining Dingdu Automation Equipment Co., Ltd. 2yr.

Contacts:Yang Bochao Chat

Mobile:86-13588876188

E-mail:13588876188@qq.com

This machine works without contact with the liquid. That is, the liquid does not pass through the pump body but flows through the pipes, ensuring no contamination during the filling process, avoiding cleaning. Different liquids are equipped with a set of pipes, with an error of 1%. It can be filled at a temperature of 170 degrees. For different corrosive liquids, special pipes made of different materials are used. It is particularly suitable for filling machines for strong corrosive, high-temperature, or multi-type liquid filling.One variety of pipe is sufficient for one set.Avoid cross-contamination between different products, eliminating the hassle of cleaning tubes,Use hygiene, save time, convenience, practical.

Applicable to:Juice drinks, alcoholic beverages, mineral water, purified water, oils, hair care products, skin care products, cosmetics, cleaning and laundry products, glue, oral liquids, medicines, liquid alcohol, wax, superglue, UV glue, engine oil, diluent, latex, organic solvents, chemical liquids.

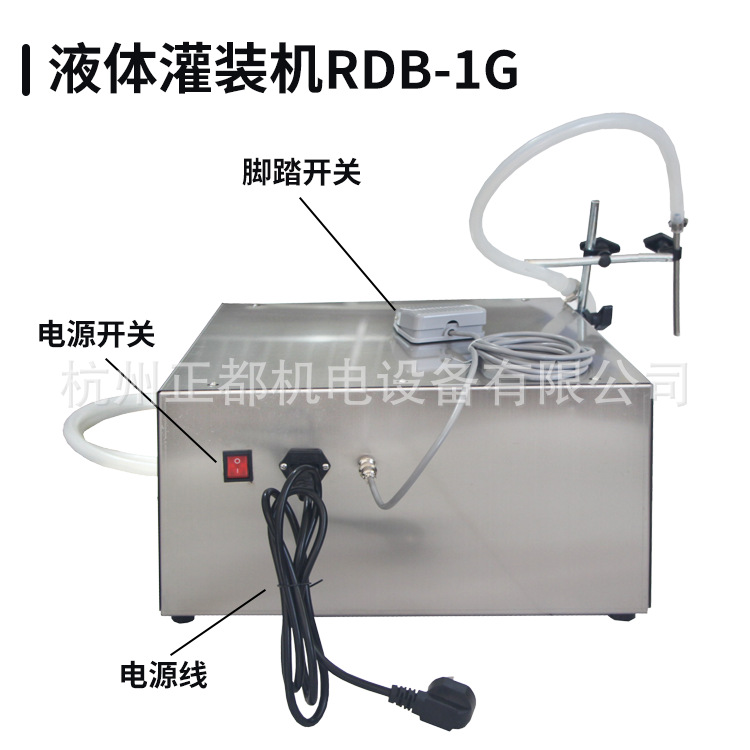

If you need to watch the filling work video, please enter the model number of the machine on Youku video. This is the RDB-1G, which can be customized to meet various specifications for the filler. Dealers can contact us directly for negotiations.

Technical parameters:

Working Power Supply: AC220V

Power: 300w

Flow rate: 12,000 ml/minute

Delay Range: 0.01s~999.9s

Counting range: 1 to 59999 times

Work Mode: Power-on Delay Data Program Setting

Display mode: top row shows filling time, middle row shows interval time, bottom row shows count.

Error: 1%

Filling nozzle diameter: 8mm

Body Material: Stainless Steel

Name: Liquid Multi-Functional Filling Machine

Model: RDB-1G

This machine uses an electric motor-driven peristaltic pump, controlled by a microcomputer to set the working and rest periods, enabling automatic and precise filling. It also automatically sets the tube-filling time.

Suitable for filling thick liquids such as cooking oil, detergent, 502 adhesive, engine oil, and salad oil, with high flow rate.

Usage Method

Prepare the liquid to be filled, connect the 220V power supply, adjust the filling time and the interval time, set the timer, press the point-and-click switch to test the machine, ensure that the motor is working normally, press the manual key, and control the filling machine with the foot switch, press once to operate the filling machine once, and press the automatic key to let the filling machine work continuously automatically according to the set time.

Steps

1. Set time adjustment A, press the setting key, the time flashes, press the increase key 0-9 to set the time required for the position. B, then press the right shift to the specified position, press the increase key to adjust the time for the position, and repeat the operation. C, press the unit key to move the decimal point forward and backward to determine the time unit. D. Press the exit key to complete the setting.

2. Adjustment of Intermission Time: The same as the adjustment of filling time.

3. Timer Adjustment

A. Press the setting key, and the timer will flash. Press the increase key 0-9 to adjust the quantity of the position, and press the right shift key to adjust the quantity of other positions. Set the required quantity.

B. Press the mode key, and when the light is on, the filling machine will stop working when the specified quantity is reached. If the light is off, the machine will continue to work and count continuously.

4. Filling Setting Press the filling setting to start the filling machine. When the filling reaches the desired amount, press the filling setting key again. The time displayed on the filling time is the time required to fill the amount.

The unique feature of this machine is

1. Filling time can be adjusted to 999 seconds.

The controller of this machine has the function of filling setting, which means it can quickly set the required time for the filling amount.

3. The filling machine controller typically uses full-Chinese display for easy operation and understanding.

4. Can be filled with relatively viscous liquids

5. Using a step motor, the speed is more stable and the working time is longer.

Suitable for the filling of chemical products such as organic solvents, the liquid does not pass through the pump body, and a silicone tube is used to deliver the liquid, which does not contaminate and has good performance for filling corrosive liquids.

7. Suitable for filling a variety of different liquids, no need to clean, changing the tubes can achieve the conversion of filling different liquids. Convenient, non-polluting, convenient for one machine to be used for multiple purposes.

8. Adopting the principle of peristaltic pump, the error is 1%, which is very stable.

Customers needing to issue an invoice, add 11% VAT tax, and add 1% tax for ordinary invoice.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Update time:

TOP