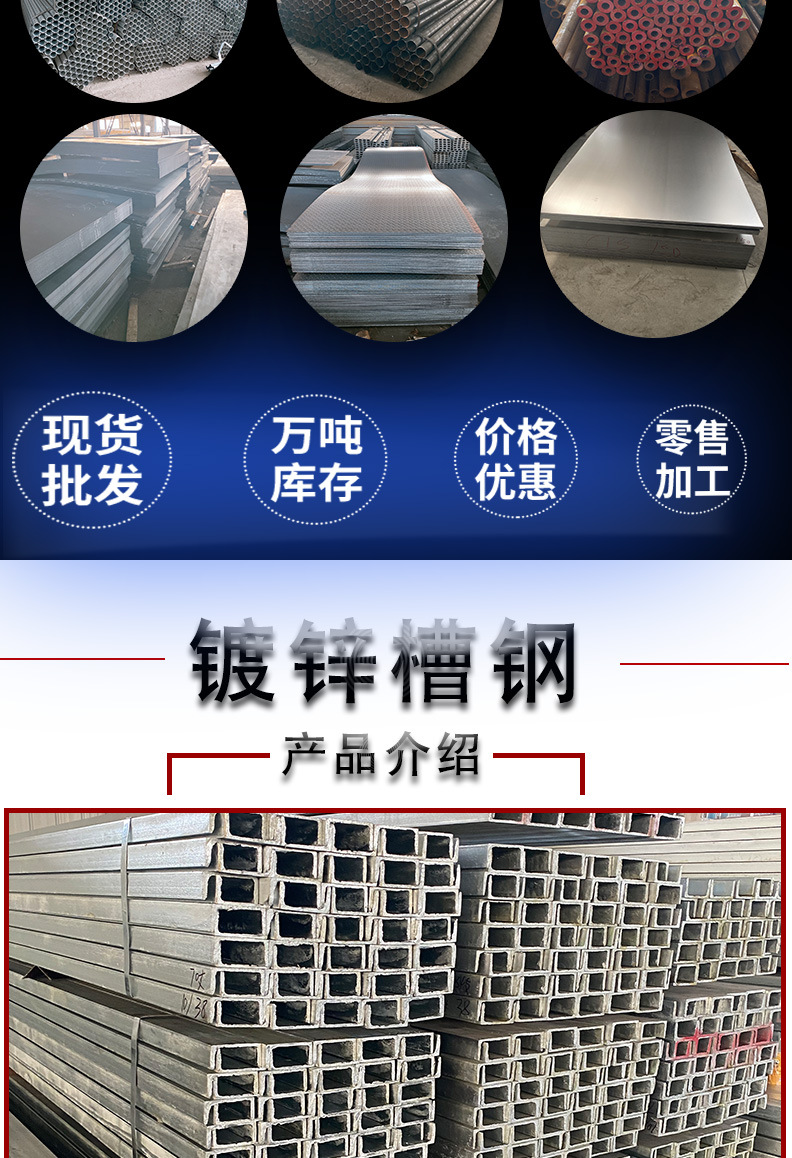

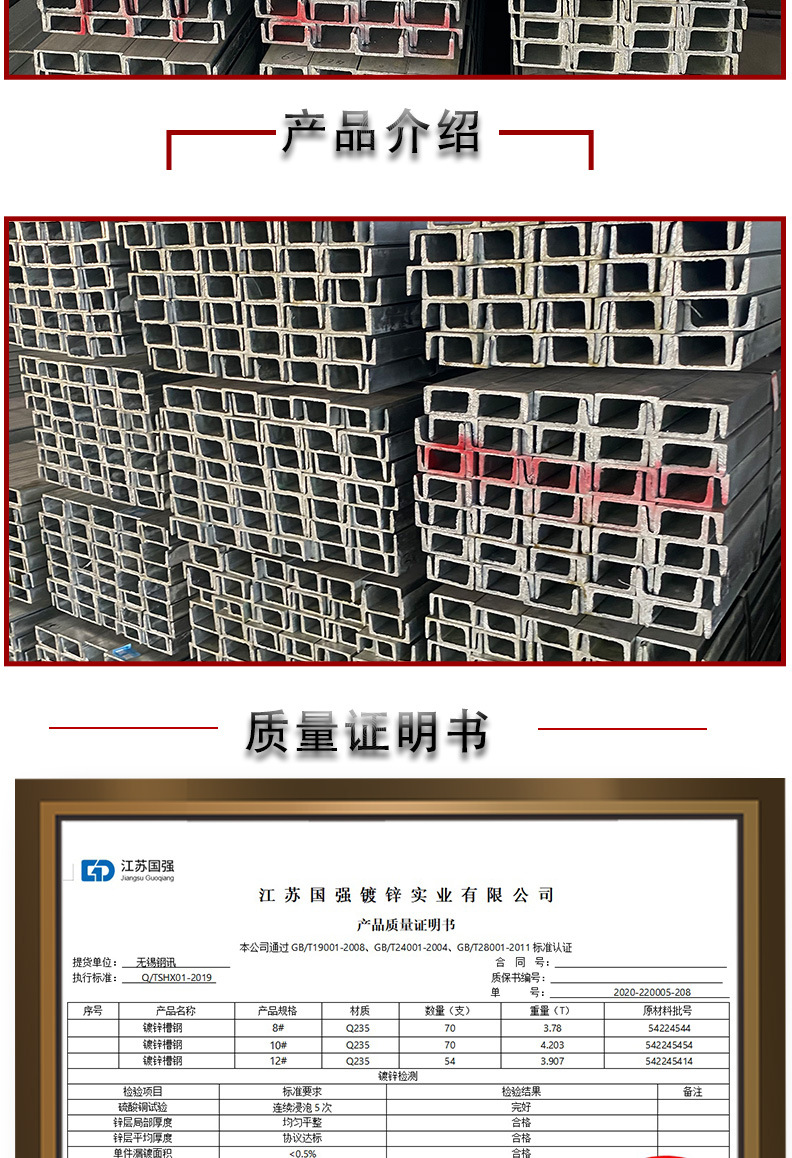

Introduction to Galvanized Channel Steel

Hot-dip galvanized channel steel, also known as hot-dip galvanized channel steel and hot-dip galvanized steel channel, is an effective metal corrosion prevention method, mainly used in the metal structure facilities of various industries. It is to immerse the channel steel after descalbing into the molten zinc at about 440~460℃, so that the surface of the channel steel is attached with a zinc layer, thereby achieving the purpose of corrosion prevention. Nowadays, the main method of surface galvanizing of channel steel is hot-dip galvanizing.

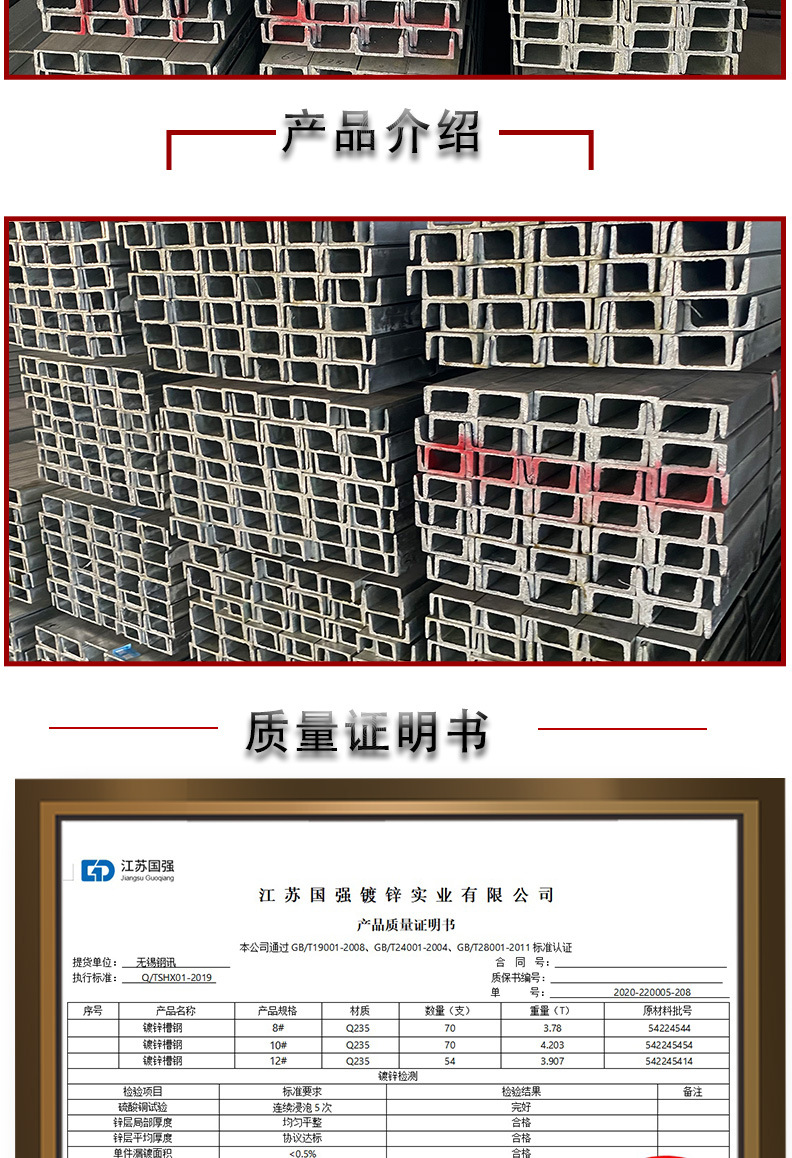

Shape Description

Hot-dip galvanized channel steel is a long strip steel with a cross-section in the shape of a recessed channel. Its specifications are indicated by the number of millimeters for the height (h), leg width (b), and thickness (d) of the waist, such as 120*53*5, which indicates a channel steel with a waist height of 120 mm, leg width of 53 mm, and waist thickness of 5 mm, or referred to as 12# channel steel. For channel steel with the same waist height, if there are several different leg widths and waist thicknesses, they also need to be distinguished by adding a, b, c after the model on the right, such as 25a#, 25b#, 25c#, and so on.

Features

1)A thicker and dense pure zinc layer is coated on the surface of steel, which can avoid the contact between the steel substrate and any corrosive solution, protecting the steel substrate from corrosion. In general atmosphere, a thin and dense layer of zinc oxide is formed on the surface of the zinc layer, which is difficult to dissolve in water, thus playing a certain protective role for the steel substrate. If the zinc oxide forms insoluble zinc salts with other components in the atmosphere, the corrosion-resistant effect will be even more ideal.

(2) With a iron-zinc alloy layer, the combination is compact, and it exhibits unique corrosion resistance in marine salt fog atmosphere and industrial atmosphere.

(3) Due to the strong combination, zinc-iron intermingle, and they have a very strong wear resistance.

(4) Due to zinc's good ductility, the alloy layer adheres firmly to the steel substrate, so hot-dip articles can be subjected to various forming processes such as cold striking, rolling, drawing, and bending without damaging the coating.