Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

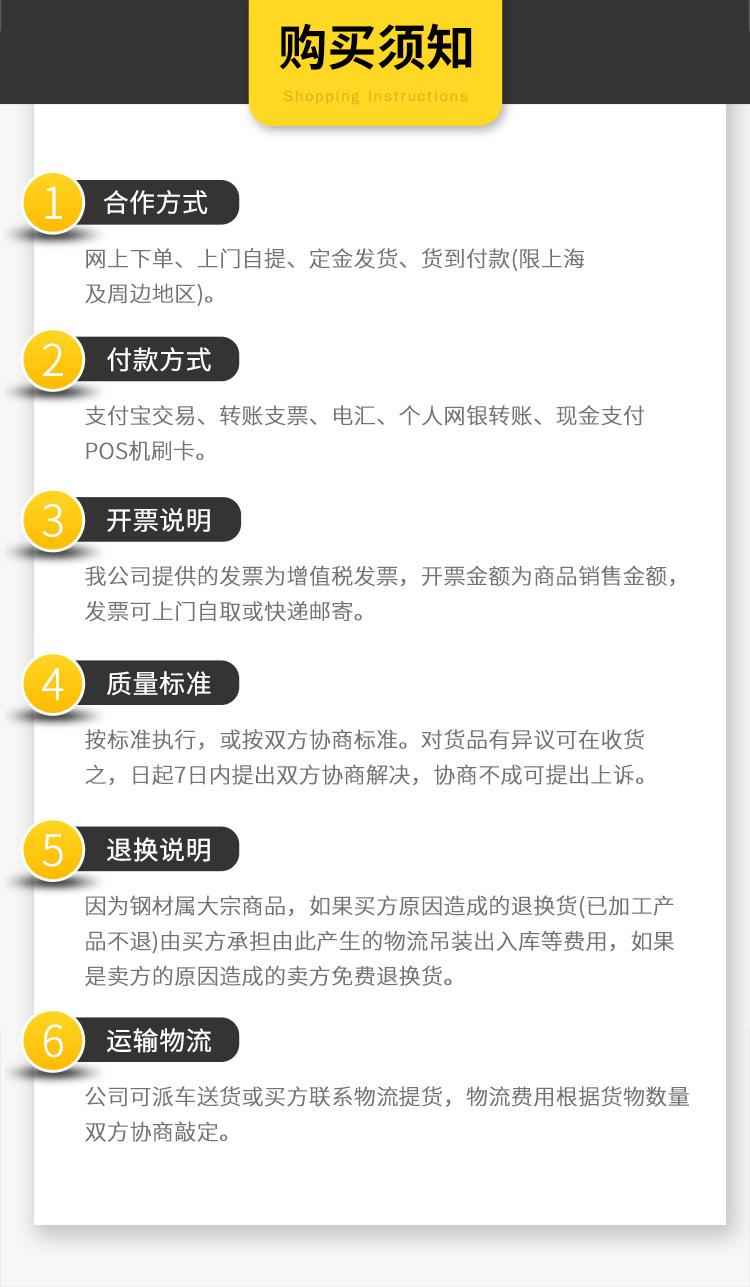

| please consult customer service for quotation before placing an order. | CN¥ 4.5 |

Shanghai Fuzhe Industrial Co., LTD 2yr.

Contacts:He Chat

Mobile:86-18018178808

E-mail:13918022919@163.com

Due to the daily fluctuations in steel prices, the shop prices are for reference only. If you need to cooperate, please call the customer service manager to inquire about the stock quantity, quotation, processing, and delivery matters for that day. Any inconvenience caused is kindly requested for your understanding.

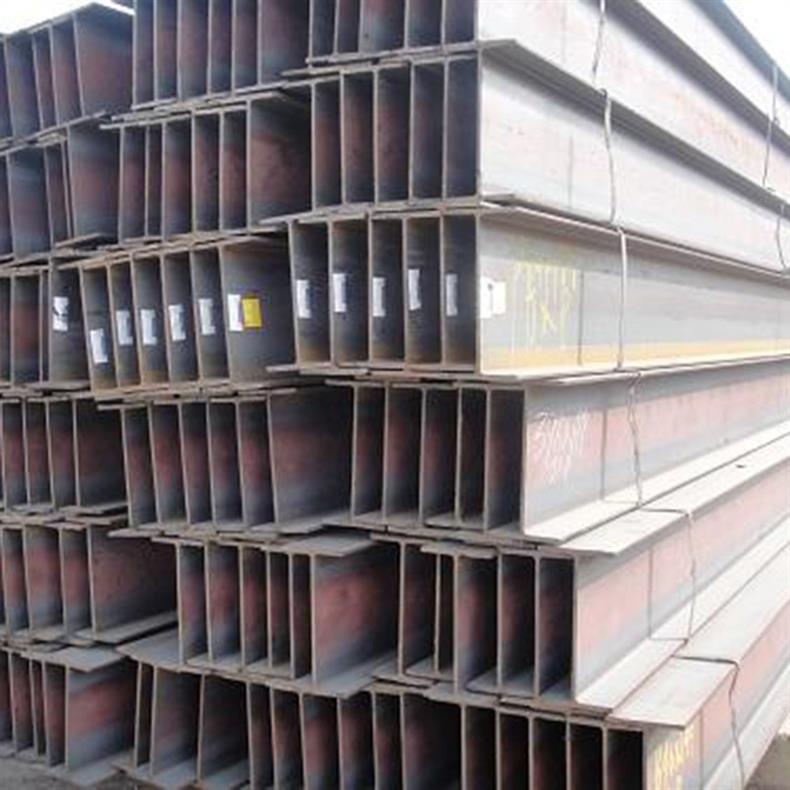

H-section steel is an efficient type of steel with a more optimized cross-sectional area distribution and a more reasonable ratio of strength to weight, named after its cross-sectional shape resembling the letter "H" in the Latin alphabet. Due to the straight angles in its layout, H-section steel exhibits advantages such as strong bending resistance, simple construction, cost-saving, and light structural weight, making it widely used in various applications. This type of steel, with a cross-sectional shape similar to the capital Latin letter "H," is also known as universal steel beams, wide flange (edge) I-beams, or parallel flange I-beams. The cross-section of an H-section steel typically includes two parts: the web and the flange plates, also known as the waist and the edges.

The flanges of H-beams are parallel or nearly parallel on both sides, with the ends at right angles, hence the name parallel flange I-beam. The web thickness of H-beams is smaller than that of ordinary I-beams with the same height, and the flange width is larger, hence the name wide flange I-beam. Due to their shape, the section modulus, moment of inertia, and corresponding strength of H-beams are significantly superior to those of ordinary I-beams with the same weight. Used in different metal structures, whether under bending moments, pressure loads, or eccentric loads, they show superior performance, enabling a significant increase in bearing capacity compared to ordinary I-beams, saving metal by 10% to 40%. The wide flange, thin web, and variety of sizes of H-beams make them flexible to use, saving metal by 15% to 20% in various truss structures. Due to the parallel flanges and right-angle ends, they are convenient for assembly and combination into various components, thereby reducing welding and riveting work by about 25%, which can greatly accelerate the construction speed and shorten the construction period.

H-beam, Round Steel, Channel Steel, Angle Steel, Seamless Pipe, Square Steel, Plate Steel, I-beam

Update time:

TOP