Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

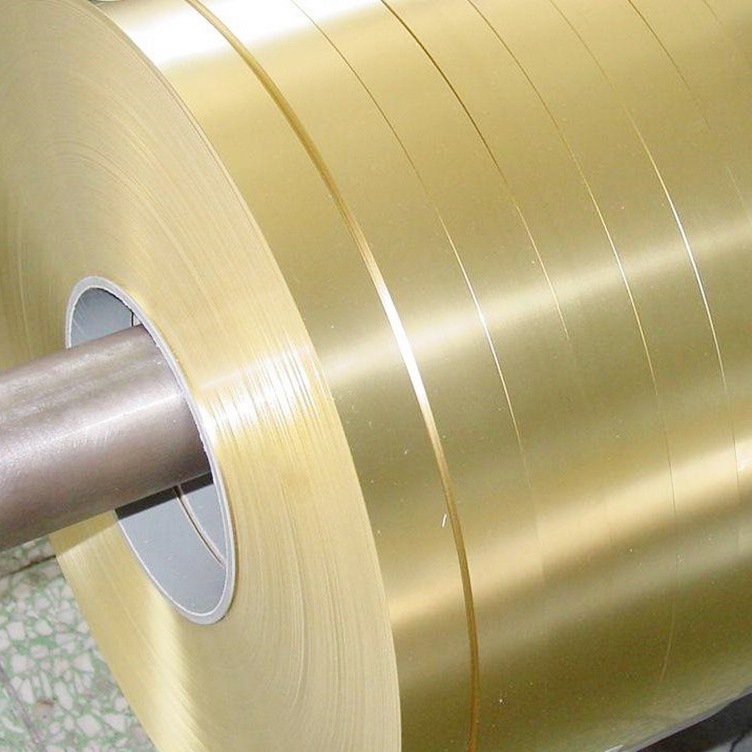

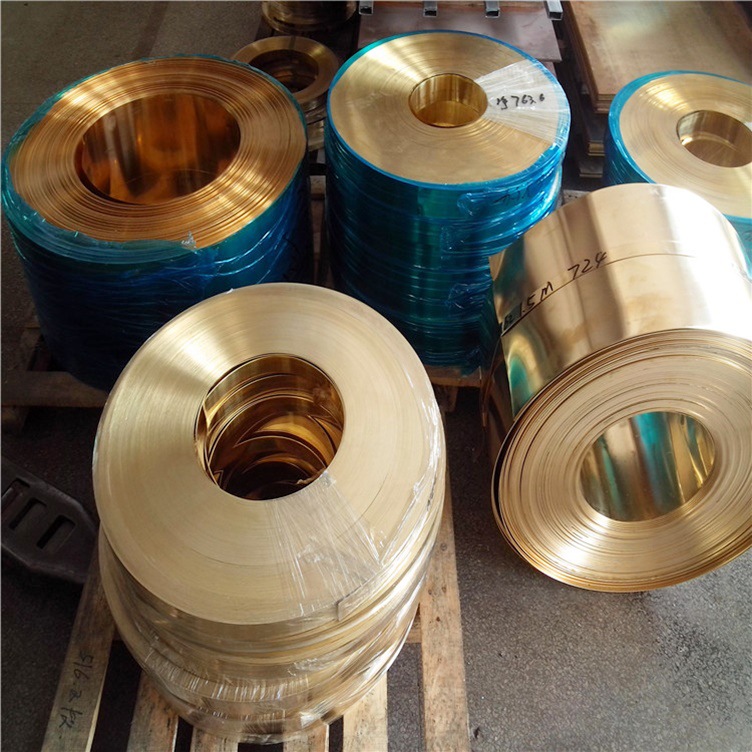

XIN HONG Materials Co,.Ltd. 12yr.

Contacts: Mr LI Chat

Mobile:86-18066212379

E-mail:2402493303@qq.com

Packaging information

CTN Size: 600 × 200 × 200 cm

G.W./CTN:2000 kg

QTY/CTN:1000 kg/carton

Brass is an alloy of copper and zinc, named for its yellow color. The national standard is...Brass used"H+"标示"indicates asH80andH70、H68、H65And so on.Brass has excellent mechanical properties and wear resistance, making it suitable for manufacturing precision instruments and parts for ships. The sound of brass is pleasant to the ear, which is why gongs, cymbals, bells, and trumpets are made from brass.

Naval Brass Copper alloys with zinc and tin are resistant to sea water erosion and can be used to make ship parts and balance weights.

brasshardness National standards haveFive different hardness states, as follows:

Soft state1/4 hard, 1/2 hard, hard state, and extra hard.

Take H65 brass as an example, the specific hardness standards are as follows:

H65M - Hardness below 100HV (soft condition) - Corresponding international grade C2680-O

H65-Y4 - Hardness 75-125HV - Corresponding international grade C2680-1/4H

H65-Y2 - Hardness 85-145HV - Corresponding International Grade C2680-1/2H

H65-Y - Hardness 105-175HV - Corresponding international grade C2680-H

H65-T - Hardness ≥ 145 - Corresponding international grade C2680

|

Hegold numberArticles |

Chemical compositionComposition |

Total ImpuritiesTotal Impurity |

||||

|

GB/T |

DIN/ASTM/JIS |

Copper |

lead |

Zn |

||

|

≤0.15 |

≤0.5 |

|||||

|

H65 |

JIS C2700 |

63.5-68.0 |

≤0.03 |

Residual quantity |

≤0.1 |

≤0.3 |

|

H68 |

JIS C2680 |

67.0-70.0 |

≤0.03 |

Residual quantity |

≤0.1 |

≤0.3 |

|

H63 |

JIS C2720 |

62.0-65.0 |

≤0.08 |

Residual quantity |

≤0.15 |

≤0.3 |

|

H70 |

JIS C2600 |

68.5-71.5 |

≤0.03 |

|

≤0.1 |

≤0.2 |

|

H90 |

JIS C2200 |

89.0-91.0 |

|

|

≤0.1 |

|

|

Alloy |

||||||||

|

state |

Specification |

Tensile strength (")megapascal) |

elongation |

state |

Specification |

Tensile strength (")megapascal) |

elongation |

|

|

H62 H63 |

Y2 |

5-20 |

≥370 |

≥15 |

M(0) |

0.05-1 |

≥335 |

≥18 |

|

Y2 |

0.05-1 |

≥410 |

- |

|||||

|

Y1 |

0.05-1 |

540-785 390-685 350-550 |

- |

|||||

|

Y(H) |

0.05-1 |

685-980 540-835 500-700 |

- |

|||||

|

H65 |

M(0) |

5-40 |

≥295 |

≥40 |

M(0) |

0.05-1 |

≥325 |

≥18 |

|

Y2 |

0.05-1 |

≥400 |

- |

|||||

|

Y(H) |

5-40 |

≥390 |

- |

Y1 |

0.05-1 |

490-735 490-685 470-670 |

- |

|

|

Y(H) |

0.05-1 |

635-885 490-785 470-670 |

- |

|||||

|

H68H70 |

M(O) |

13-35 |

≥295 |

≥45 |

M(O) |

0.05-1 |

≥355 |

≥18 |

|

Y2 |

5-12 |

≥370 |

≥15 |

Y2 |

0.05-1 |

≥390 |

- |

|

|

Y1 |

0.05-1 |

490-735 |

- |

|||||

|

Y(H) |

0.05-1 |

685-93 |

- |

|||||

|

H90 |

M(O) |

5-80 |

≥205 |

≥35 |

M() |

0.05-1 |

≥315 |

|

|

Y(H) |

5-40 |

>265 |

≥4 |

Y(H |

|

|

|

Update time:

TOP