Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

mixed/2000 pcs/bag

mixed/2000 pcs/bag

|

CN¥ 0.0 |

clear #1/2000 pcs/bag

clear #1/2000 pcs/bag

|

CN¥ 0.0 |

clear #2/2000 pcs/bag

clear #2/2000 pcs/bag

|

CN¥ 0.0 |

clear #3/2000 pcs/bag

clear #3/2000 pcs/bag

|

CN¥ 0.0 |

BLINGBLING NAILS Accessories 5yr.

Contacts:Xie Xiu Chat

Mobile:86-18673108555

E-mail:23642764262882@qq.com

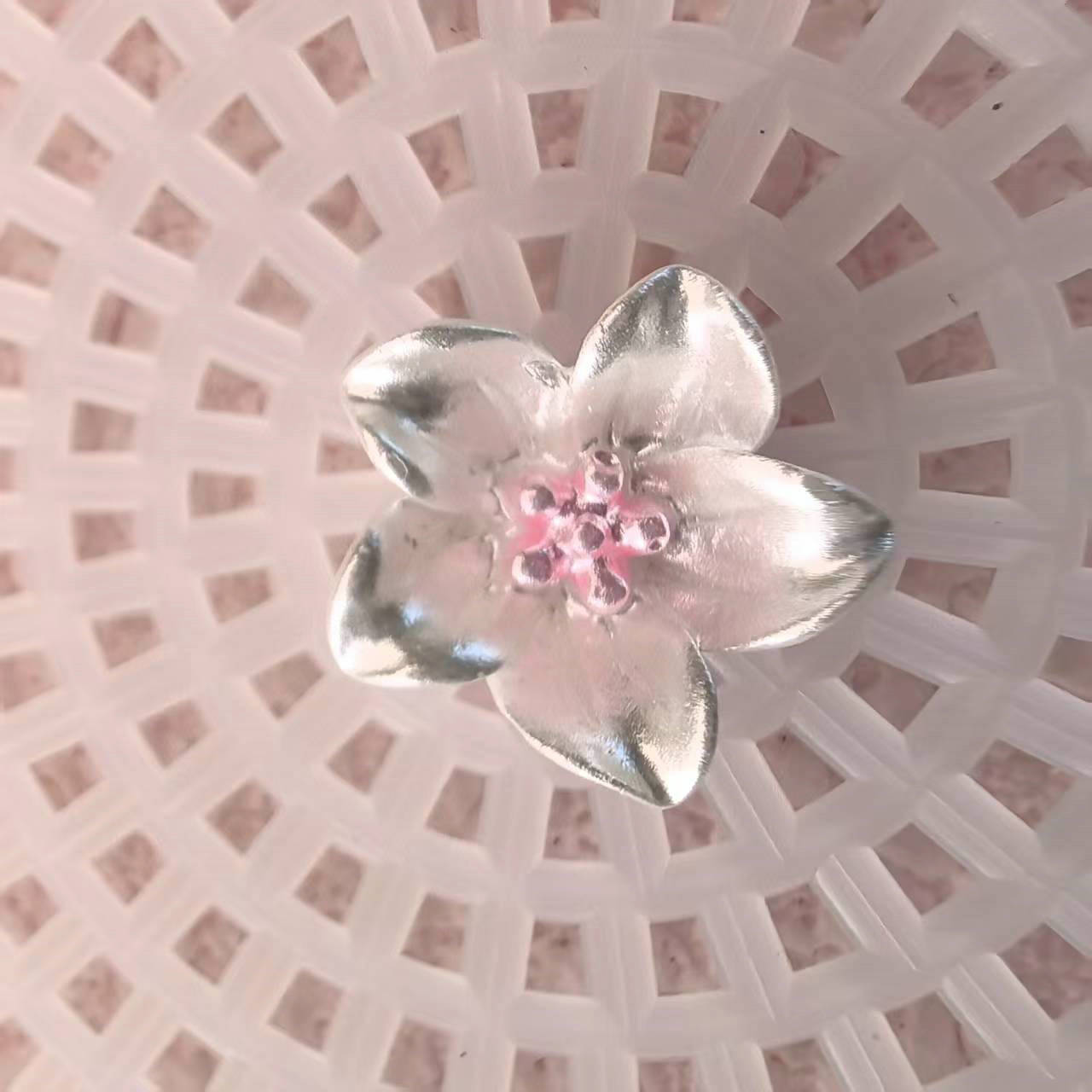

Pearl paintThe application of resin accessories in jewelry can significantly enhance the visual effect and commercial value of the product. Its unique iridescent effect and color changes can add a sense of sophistication and fashion to the jewelry.

1. The characteristics and advantages of pearl paint

Optical effects: Mica or synthetic iridescent powder in pearl paint can produce multi-layered light reflection, presenting a soft pearl luster, metallic texture, or rainbow-colored polarization effect.

Color Richness: By adjusting the ratio of primary color paints (such as transparent red, blue, purple, etc.) with pearl powder, different styles from low-key elegance to high saturation and vibrant colors can be created.

Lightweight: Compared to traditional metal or gemstone inlay, the pearl paint coating does not increase the weight of resin jewelry.

2. Application Scenario

Imitation of natural materials: Simulating the iridescent effects of natural gems such as mother-of-pearl, moonstone, and opal.

Theme design: suitable for starry sky, ocean, retro style and other theme jewelry, such as gradient color earrings, necklace pendants.

Brand Identity: Enhance brand recognition by customizing pearl paint colors (e.g., specific polarizing colors).

3. Key Technical Implementation Points

Material Selection

Resin substrate: It is recommended to choose smooth surface epoxy resin or UV resin to avoid cracking of the paint surface due to curing contraction.

Pearl paint type:

Water-based pearl paint: environmentally friendly and low odor, suitable for DIY, but needs to be paired with a sealing layer (such as UV glue) for water resistance.

Solvent-based metal paint: High adhesion, suitable for industrial spraying, and ventilation is necessary.

UV Curing Pearl Paint: Fast curing, suitable for mass production.

Process Steps

Surface treatment:

Resin parts are polished to a mirror finish (600# → 3000# sandpaper for grinding in stages), and the mold release agent residue is cleaned (using alcohol to wipe).

Primer Coating (Optional):

Spraying a white or black primer enhances the color intensity of pearl paint (black primer highlights a sense of depth, while white primer makes it brighter).

Pearl paint spraying:

Use a 0.3mm nozzle, adjust the air pressure to 0.2-0.3MPa, and spray multiple thin layers (2-3 layers, with a 10-minute interval between each layer).

When applying by hand, it is recommended to add 10%-15% of the diluent (compatible with the paint), to avoid brush strokes.

Curing and Protection:

Natural drying for 24 hours or UV light curing (select based on paint type);

Cover with a transparent protective layer (such as epoxy crystal or car lacquer) to prevent scratching.

Color Matching Techniques

Layered design: First, spray a base of light golden pearl paint, then apply transparent blue-purple iridescent paint in patches to create a gradient effect.

Mixed media: Mixing mica powder directly with transparent resin and casting it can produce resin parts with embedded mica (need to control the powder ratio ≤ 5%, to avoid affecting the curing).

4. Innovative Application Cases

Dynamic color-changing effect: Combining light- or temperature-sensitive pigments, the jewelry exhibits color changes at different angles/temperatures.

3D printing combination: spraying pearl paint on the inner wall of the transparent resin 3D print, covering a transparent layer on the outside, creating a three-dimensional halo effect.

Environmental alternative: Use bio-based mica-coated titanium dioxide to replace traditional synthetic materials.

5. Market and Consumer Considerations

Positioning: Pearl paint jewelry is suitable for the mid-to-high end market, with pricing comparable to that of ordinary resin jewelry at 30%-50% higher.

Promotion Highlights: Emphasize the value-added points such as "Hand Spraying" and "Color Formula".

By selecting materials and controlling the process reasonably, pearl paint can bring a unique visual appeal to resin jewelry, while balancing cost and durability. For small-scale production, it is recommended to try water-based paint with brush painting first, and for mass production, it is suggested to adopt an automated spraying line to improve efficiency.

Update time:

TOP