Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Hebei Liston Lifting Rigging Manufacturing Co. , Ltd. 3yr.

Contacts:Mrs Jessica Zhang Chat

Mobile:86-13903363509

Product Description

I. Product Overview

Customized flat lifting slings with leather protection are highperformance lifting solutions designed for specialized industrial applications These slings are constructed from highstrength polyester webbing and are strategically reinforced with exceptionally abrasionresistant leather material at critical wear pointssuch as the eyes edges or contact areas This unique combination of flexible fiber strength and rigid leather protection significantly enhances the slings service life and safety factor in demanding conditions offering an efficient customized solution

II. Key Features & Advantages

Superior Abrasion & Cut Resistance: The added leather layer effectively protects against abrasion, cutting, and tearing, making it ideal for lifting loads with rough or sharp edges (e.g., steel, machinery, stone, lumber).

Extended Service Life: The leather protector absorbs the majority of friction and wear, shielding the core polyester fibers from damage. This multiplies the sling's lifespan and reduces the total cost of ownership.

Enhanced Safety: By preserving the structural integrity of the sling, it significantly reduces the risk of accidents caused by unexpected wear and failure, complying with the highest safety standards.

High Strength & Flexibility: Maintains the inherent advantages of polyester slings: high strength-to-weight ratio, lightness, and flexibility. They are easy to handle and are non-marring to delicate surfaces.

Customization: Can be tailored to specific client requirements. The position, shape, size, and thickness of the leather pads, as well as the sling's length, width, and rated capacity (e.g., 1 ton to 100+ tons), can be customized for optimal performance.

III. Primary Applications

Steel & Metallurgy Industry: Lifting steel plates, coils, H-beams, pipes.

Heavy Machinery Manufacturing & Installation.

Construction Materials: Handling stone, concrete precast elements, glass.

Shipbuilding and Aerospace sectors.

Timber and Log Handling.

Any heavy-duty lifting operation where severe abrasion or cut risks are present.

IV. Customization Process

Requirement Consultation: Understand your load (weight, shape, surface condition) and specific wear points.

Solution Design: Our engineers design a protection plan, determining the location and method of leather reinforcement.

Parameter Confirmation: Finalize sling specifications (length, width, capacity), leather type, and thickness.

Manufacturing: Precision fabrication using high-tenacity sewing threads and techniques.

Rigorous Testing: Every custom sling undergoes strict testing to ensure it meets the rated capacity and safety standards.

Delivery & Support: Provided with product certification and safe use guidelines.

一、 产品概述

加皮料定制扁平吊装带是一种专为满足特殊工业吊装需求而设计的高性能吊装索具。它在标准高强度聚酯纤维扁平吊装带的关键易损部位(如吊耳、接触边角等处)缝合或包裹了耐磨性极高的皮革材料。这种结合了柔性纤维强度与刚性皮革防护的设计,大幅提升了吊装带在苛刻工况下的使用寿命和安全系数,是一种高效的定制化解决方案。

二、 核心特点与优势

非常耐磨防护:增加的皮革层能有效抵御磨损、切割和撕裂,特别适用于吊装表面粗糙、有尖锐边角的货物(如钢材、机械设备、石材、木材等)。

延长使用寿命:皮革保护层吸收了大部分摩擦和磨损,使核心的聚酯纤维部分免受损害,从而将吊装带的使用寿命延长数倍,降低了综合使用成本。

增强安全性:通过保护吊装带主体结构完整性,显著减少了因意外磨损断裂而导致的安全事故风险,符合安全作业的最高标准。

高强度和柔性:保留了聚酯纤维吊装带固有的高强度、轻质和柔软特性,便于操作和打结,同时不会损伤货物表面。

定制化设计:可根据客户的具体需求,定制皮革保护垫的位置、形状、大小和厚度,以及吊装带的长度、宽度和额定载荷(如1吨至100吨以上),实现最好匹配。

三、 主要应用场景

钢铁冶金行业:吊装钢板、钢卷、H型钢、钢管等。

重型机械设备制造与安装。

建筑材料行业:搬运石材、水泥预制件、玻璃等。

造船业和航空航天领域。

木材加工和运输。

任何存在严重摩擦和切割风险的重型吊装作业。

四、 定制流程

需求沟通:了解您的吊装物、重量、形状、表面状况及具体磨损痛点。

方案设计:我们的工程师会设计保护方案,确定皮革加装的位置和方式。

参数确认:确定吊装带的规格(长度、宽度、载荷)、皮革类型及厚度。

生产制造:采用高强度缝纫线和工艺进行精密加工。

严格测试:每一条定制吊装带都经过严格测试,确保符合额定载荷和安全标准。

交付使用:提供产品认证资料和安全使用指导。

Packaging & Shipping

Packaging & Shipping

Our Services

1.Client

WenbsptreasurenbspandnbsptrynbsptonbspunderstandnbspallnbspthenbspdifferentnbspneedsnbspofnbspournbspclientsnbspandnbspseeknbsptonbspforgenbspanbsplongnbsptermnbspprofessionalnbsprelationshipnbspwithnbspthemnbspThenbspsatisfactionnbspofnbspeachnbspandnbspeverynbspcustomernbspisnbspournbspmainnbspgoalnbspandnbspmotivationnbspinnbspconductingnbspournbspbusiness

2.People

Weworkasateamandtreateachotherwithrespect.Oursolid,capableandknowledgeableteamisvaluedasthegreatestassetandanintegralpartofthebusiness.

3.Product

Ourproductsareofhighqualitystandardsandalwayscomewithcertificateofcompliancebythemanufacturers.

4.Performance

Weaimtoachievehighlevelofperformanceandsatisfactiontobothourclientandpeople,whichincludedeliveringhighqualityservicesandtreatingpeoplewithintegrity.

5.FreesampleandOEMservice

WecanprovidefreesamplestoyouandwealsohaveOEMservice,wecanputyour

logoonthelabelandtheinformationyouneedonthewebbingtoo.

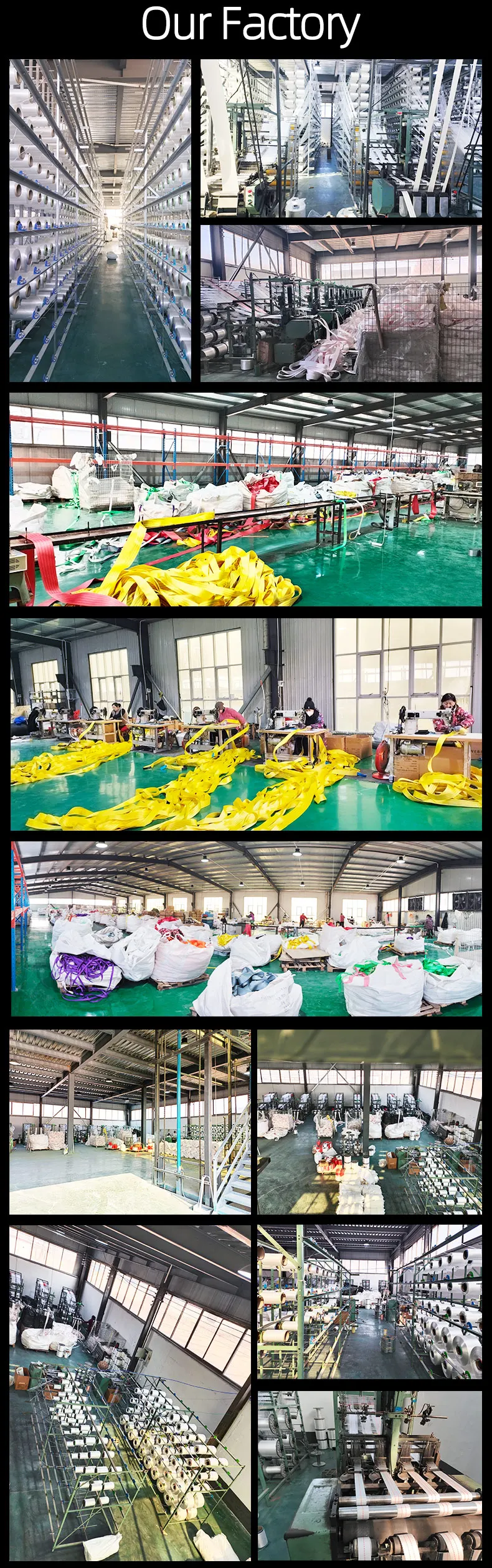

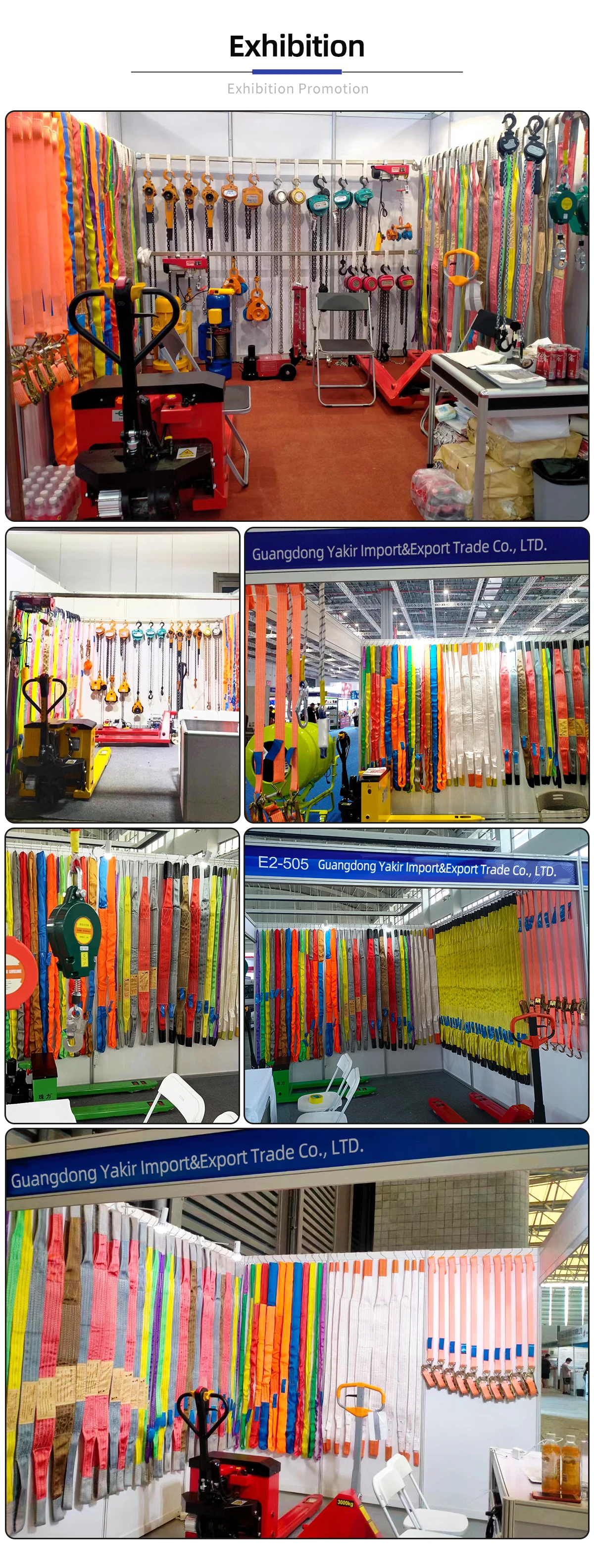

Hebei Liston Lifting Rigging Manufacturing Co., Ltd.is a modern enterprise dedicated to the research and development, production, sales, and service of various lifting machinery supporting equipment.

The company mainly produces lifting belts lifting belt combination slings chain combination slings cargo bundling devices car tensioners car trailer straps lifting tongs transport vehicles micro electric hoists CD1 electric hoists multifunctional elevators pneumatic jacks pneumatic tire scrapers speed difference fall protectorslifting chains and other products with an annual production capacity of 200000 units.

Hebei Liston has introduced a synthetic fiber lifting belt production line which can meet the manufacturing needs of various universal lifting slings The existing process equipment can complete the weaving printing and dyeing heat treatment sewing and core piercing of synthetic fiber lifting belts At presentthere are over a hundred types of lifting belts complete sets of rigging binding belts lifting hoists and other major product series produced widely used in industries such asnbspmetallurgy, power, petroleum, aerospace, aviation, chemical, aircraft maintenance, mining, construction, etc.

The company has established a series of strict management structures, quality assurance systems, and testing methods in the spirit of"taking technology as the guide, survival through quality, development through reputation, and efficiency through strict management".We continuously innovate and provide stable quality and reasonably priced products to the market.

The company is located in Donglv Industrial Park Hebei Province which is one of the few production bases for lifting belts in China It has a superior geographical location and convenient transportation Our company will adhere to the business philosophy of integrity innovation and winwin adhere to the development policy ofpeopleoriented quality oriented continuously improve our competitiveness provide customers with more products and services downtoearth and face the future

公司信息

河北立诗顿起重索具制造有限公司是一家致力于研发、生产、销售和服务各种起重机械配套设备的高新技术企业。

本公司主要生产:吊带、吊带组合吊具、链条组合吊具、货物捆扎设备、汽车捆绑带、汽车拖车带、吊钳、搬运车、微型电动葫芦、CD1电动葫芦、多功能提升机、气动千斤顶、气动轮胎扒胎机、速度差保护器、起重链条等产品,年生产能力达20万台套。

河北立诗顿已引进合成纤维吊带生产线,可满足各种通用吊带的制造需求,现有工艺设备可完成合成纤维吊带的织造、印染、热处理、缝制、芯钻等工序,目前已拥有吊带、成套索具、捆绑带、吊装机具等百余个品种的生产,广泛用于冶金、电力、石油、航天、航空、化工、飞机维修、矿山、建筑等行业。

公司本着"以科技为先导,以质量求生存,以信誉求发展,以严格管理求效益”的精神,建立了一系列严格的管理结构、质量保证体系和检测方法。我们不断创新,向市场提供稳定质量和合理价格的产品。

公司座落于河北省东闾工业园,是中国为数不多的安全带生产基地之一,地理位置优越,交通方便,我公司秉承"诚信、创新、共赢”的经营理念,坚持"以质量求生存,以信誉求发展,以管理求效益”的宗旨,竭诚为国内外客户服务。

FAQ

Q1:Whatisyourtermsofpacking?

A1:Generally,wepackourgoodsinneutralcartons.Ifyouhavelegallyregisteredpatent,wecanpackthegoodsinyourbrandedboxesaftergettingyourauthorizationletters.

Q2:Whatisyourtermsofpayment?

A2:T/T30%asdeposit,and70%beforedelivery.We'llshowyouthephotosoftheproductsandpackagesbeforeyoupaythebalance.

Q3:Whatisyourtermsofdelivery?

A3:EXW,FOB,CFR,CIF,DDU.

Q4:Howaboutyourdeliverytime?

A4:Generally,itwilltake5to30daysafterreceivingyouradvancepayment.Thespecificdeliverytimedependsontheitemsandthequantityofyourorder.

Q5:Canyouproduceaccordingtothesamples?

A5:Yes,wecanproducebyyoursamplesortechnicaldrawings.Wecanbuildthemoldsandfixtures.

Q6:Whatisyoursamplepolicy?

A6:Wecansupplythesampleifwehavereadypartsinstock,butthecustomershavetopaythesamplecostandthecouriercost.

Update time:

TOP