Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| smic cast 308 2.5mm per kilogram | CN¥ 146.3 |

| smic cast 308 3.2mm per kilogram | CN¥ 146.3 |

| smic cast 308 4.0mm per kilogram | CN¥ 146.3 |

| smic cast 408 2.5mm per kilogram | CN¥ 110.0 |

| smic cast 408 3.2mm per kilogram | CN¥ 110.0 |

| smic cast 408 4.0mm per kilogram | CN¥ 110.0 |

| smic z508 2.5mm per kilogram | CN¥ 170.5 |

| smick z508 3.2mm per kilogram | CN¥ 170.5 |

| smick z508 4.0mm per kilogram | CN¥ 170.5 |

Yiwu WANYING e-commerce firm factory direct sales 6yr.

Contacts:Manager Wang Chat

Mobile:86-18769568261

E-mail:1032644595@qq.com

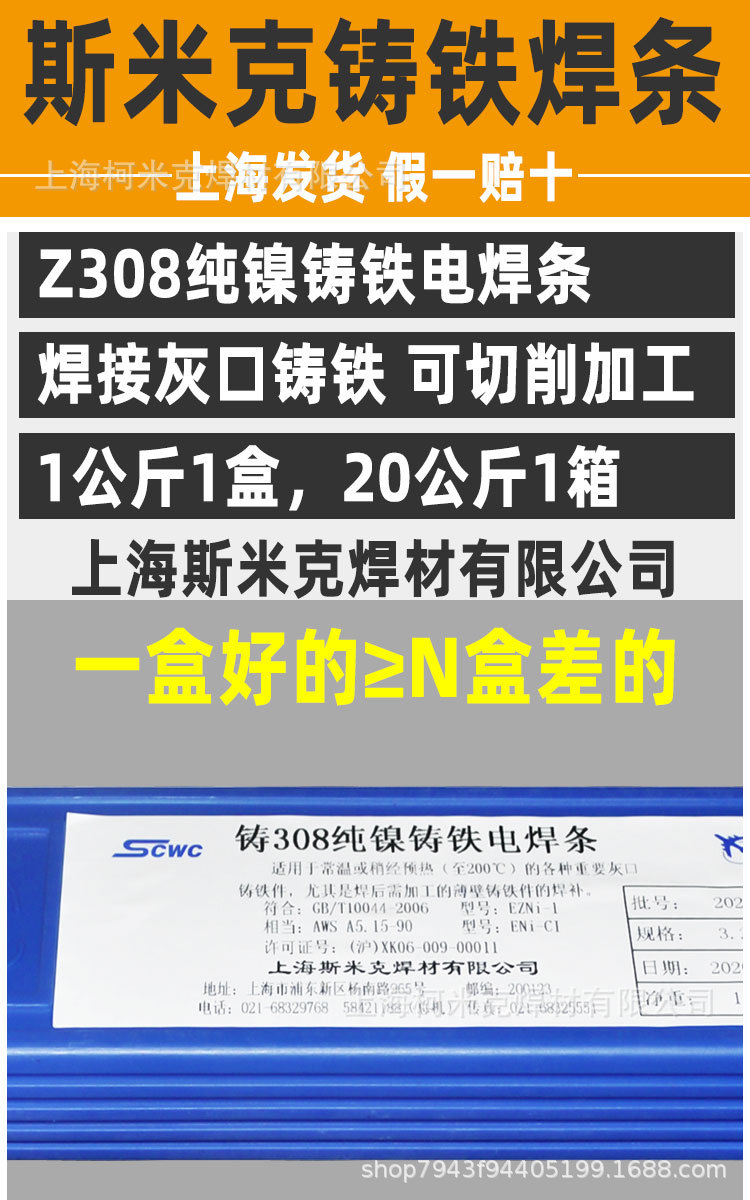

Name: Cast 308 Pure Nickel Electrode for Cast Iron

Standard: GB/T 10044 EZNi-1 AWS A5.15ENi-CI

Ingredients:C=2.0%;Si≤2.5%;Mn≤1.0%;Ni≥90%;Fe=8.0%;S≤0.03%。

Explanation:Z308This is a cast iron welding rod with pure nickel as the welding core and a strong reducing graphite type coating. It can be used for welding cast iron.AC/DC dual-use. The arc during welding is stable and the operation is convenient, and the welding piece does not need to be preheated. It is one of the cold welding methods for cast iron, with good anti-cracking properties and Cutting machinabilityThis type of welding wire has good comprehensive performance, including weld strength, and is widely used for the spot welding of thin cast iron parts and machined surfaces.

Usage:For welding of gray cast iron. The welding of thin cast iron parts and machining surfaces, such as cylinder heads, engine blocks, machine tool guides, motor housings, gearboxes, and other important gray cast iron components. It is also suitable for welding cast iron mechanical parts, etc.

Hardness: HB180

Name: Cast 408 Cast Iron Nickel-Iron Electrode

Standard: GB/T 10044EZNiFe-1 AWS A5.15 ENiFe-CI

Ingredients:C=2.0%;Si≤4.0%;Mn≤2.5%;Ni=45-60%;Fe=balance;S≤0.03%。

Explanation:Z408It is a cast iron electrode with a nickel-iron alloy core and a strong reducing graphite coating. It has high strength, good plasticity, and low coefficient of linear expansion. Its anti-cracking performance is similar to that of gray cast iron and Z308, but it is stronger for ductile cast iron than Z308. It also has good effect on cast iron with high phosphorus content (about 0.2% P), but the cutting and machining performance is slightly worse than Z308 and Z508. It is used for welding gray cast iron and ductile cast iron at room temperature or slightly preheated (to about 200℃).AC and DC dual-use.

Usage:Suitable for the welding of important high-strength gray cast iron and ductile iron castings. Examples include cylinder blocks, engine blocks, gears, rollers, etc.

Hardness: HB200

Name: Cast 508 Nickel-Copper Cast Iron Electric Welding Rod

Standard: GB/T 10044 EZNiCu-1 AWS A5.15ENiCu-B

Ingredients:C=0.35-0.55%;Si≤0.75%;Mn≤2.3%;Ni=60-70%;Cu=2.5-3.5%;Fe=3.0-6.0%;S≤0.025%。

Usage:Suitable for patch welding of gray cast iron at room temperature or slightly preheated (up to 300°C), or for patch welding of gray cast iron processing surfaces with cracks and sand holes that do not require high strength, with cutting properties similar to those of Z308 pure nickel cast iron electrodes.

Hardness: HB160

Brand: Jinjiang (Shanghai Brand)

Manufacturer:Shanghai Simike Welding Materials Co., Ltd.

Update time:

TOP