Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| mini zvs | CN¥ 0.0 |

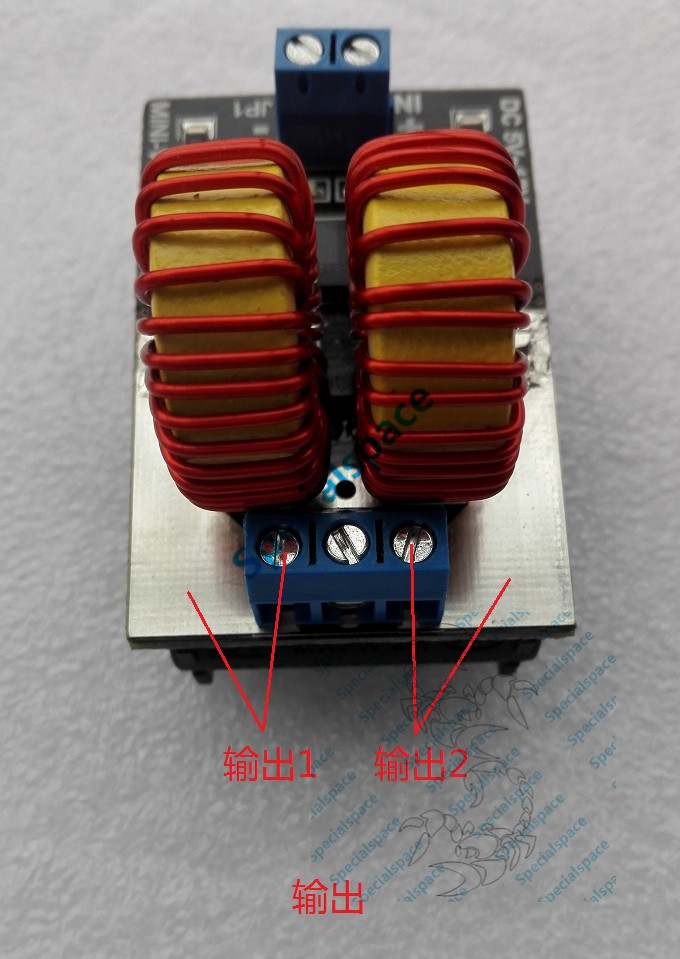

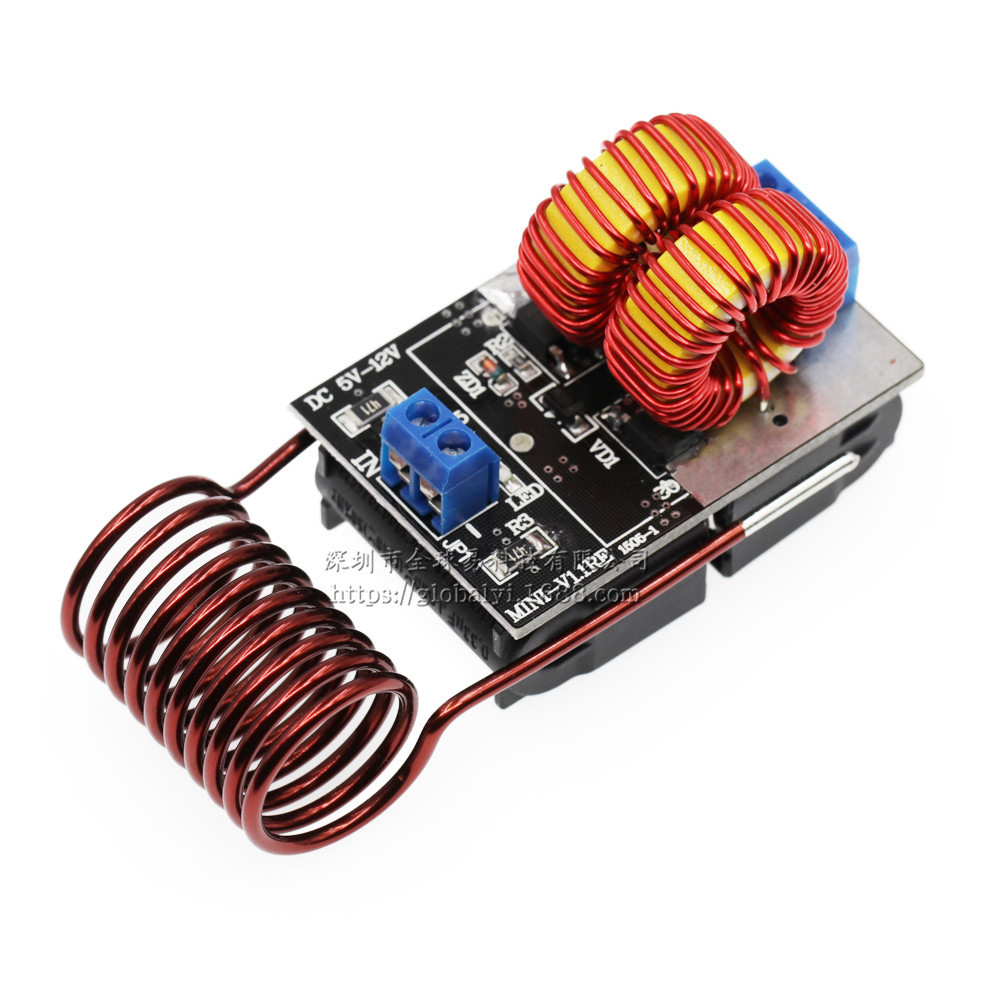

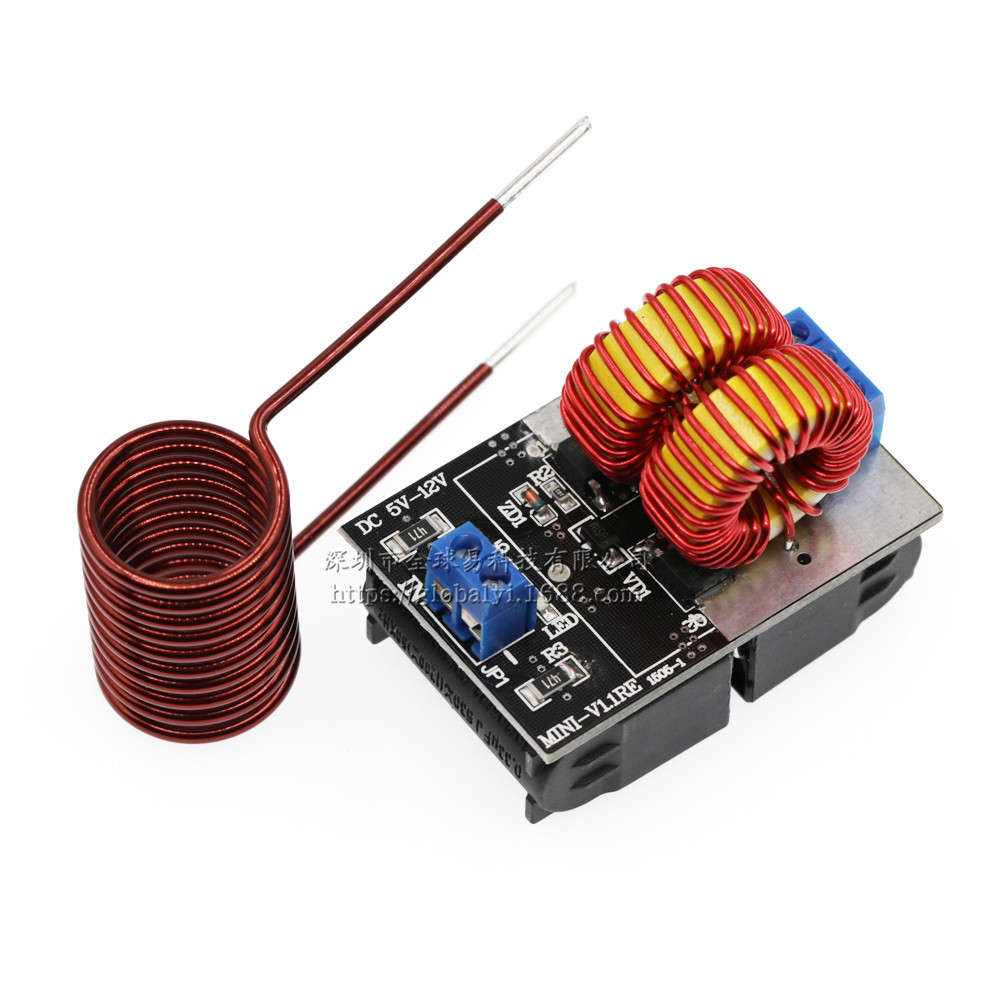

Miniature ZVS (Zero Volt Switching) No-Buck Components Induction Heating Tesla Jacob's Ladder Drive

Battery and battery power are not supported. Remember!

1. This is a pre-assembled ZVS (Zero Volt Switching) mini-board without a high-voltage transformer or a cooling fan.

2. This kit requires a certain level of handiness and relevant knowledge. If you can't even use a soldering iron or don't know the difference between the positive and negative poles of a power supply, we recommend not purchasing. If there are any problems after purchase, the seller will not assume any responsibility!

3. Power: 120W (12V when inductively heating). When pushing the high-voltage transformer with 12V and 5+5 turns in the primary, the power is about 30W.

4. Input voltage: DC 5V to 12V. This is the operating voltage range, not the voltage at the power supply without load!

The seller does not guarantee that the product will work normally if the voltage is over 12V or below 5V. If the input voltage is not within this range, the seller will not assume any responsibility for any problems that may occur!

Ensure that the working voltage is above 4.5V when using batteries or batteries to power!Do not use battery or battery power if you cannot ensure that the voltage is always above 4.5V while working!Do not use dry batteries!

5. Confirm that all components are welded correctly, and the positive and negative poles of the power cable are not connected in reverse. After connecting the load (heating coils, high-voltage coils), turn on the power! Do not power on the empty load! It is easy to damage the empty load if you power it on!

6. PCB Board Size: Length * Width * Thickness 55mm * 37mm * 1.6mm

7. Processor speed: 50Hz

8. Current: 10A

7. Heat-resisting coil

The width of the object to be heated should be as close to one-third to one-half of the diameter of the heating coil as possible, and should not exceed two-thirds!

The diameter of the heated object should be as small as possible, no larger than 20mm, as larger objects can be difficult to heat to a bright red due to the limited power.

When using inductive heating, it is generally recommended to turn off the power and cool down after 5 minutes. This is because the current is quite high during inductive heating, causing the coil to heat up significantly. During the heating process, some of the heat generated by the object being heated is transferred to the heating coil, and over time, the temperature of the coil can become quite high. If the heating coil is connected to the terminal, it can melt the plastic part of the terminal! Therefore, it is best to solder the heating coil directly to the PCB board during inductive heating. Please note this for the buyers.

It is recommended to use copper tubes for the coil and water cooling for long-term use.

8. The current generated during inductive heating is related to the input voltage, the number of turns in the primary winding, the number of turns in the heating coil, and the volume of the object to be heated.

The blue LED power indicator light tells you if the power is on or not. Just look at the light to know!

The reason why the indicator light does not light up could be: 1. The wires are not connected properly, or the power supply is not working. 2. There is a component damage on the board.

When the indicator light is dim, it should be due to insufficient power supply. You need to replace it with a larger power supply.

No-taper is more suitable for induction heating.

The heating coil can be soldered to the PCB board in this way.

12V Induction Heating Test Address:

http://v.youku.com/v_show/id_XMTI3MzYyOTkwMA==.html?firsttime=60&from=y1.4-2

Hot iron block size: length * width * height 30 * 10 * 4mm

Update time:

TOP