Pattern Printing:

1. The pattern is directly printed using an inkjet printer (requires heat transfer ink).

2. Compatible with most printers, such as the Ep series of inkjet printers.

3. Select the appropriate printer settings according to the printer user manual, taking the EP printer as an example. Set the printer to photo (P), select the paper option to be ordinary paper, and use mirror printing.

4. After the printing is complete and the product is allowed to stand and dry naturally, it can be transferred.

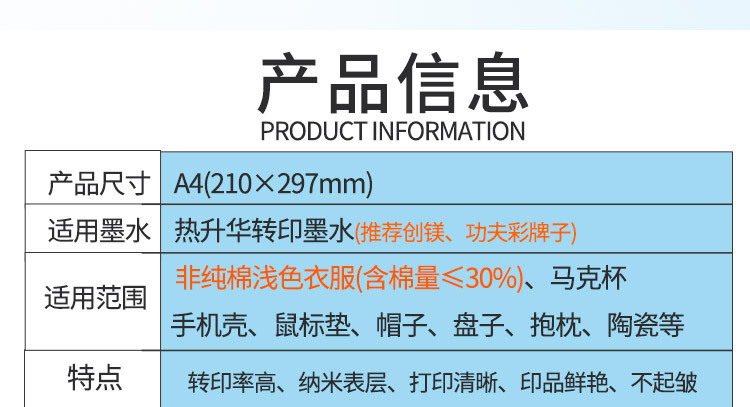

Main Use:

This product is mainly used for non-cotton light-colored clothes (synthetic fibers, polyester, team jerseys), coated cups, plates, hats, metals, glass, stone paintings, wood, key chains, makeup mirrors, jigsaw puzzles, and other items... It has no tactile sensation, and the transferred colors are bright and the color restoration is good. Usage method:

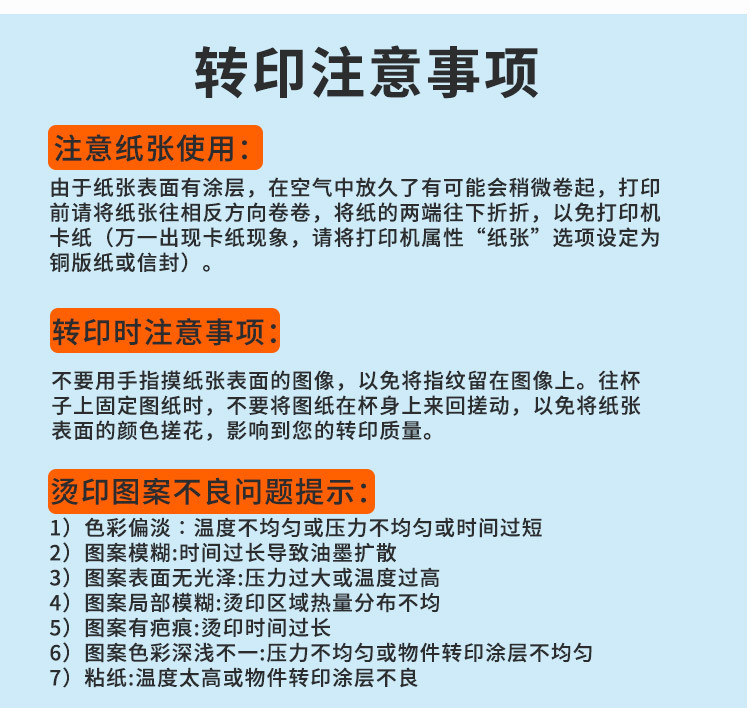

Print the pattern on the sticky side. Make sure to wait until the pattern is dry before transferring it (you can use a heat transfer machine to dry it, or use a hair dryer, but natural drying takes a long time).

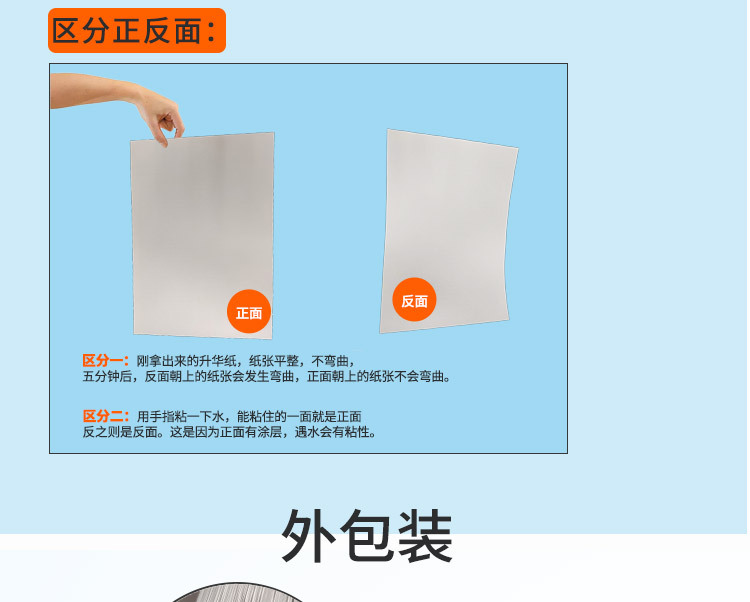

Method to distinguish front and back:

1. Wet your hands slightly with water, then pinch the two sides of the paper. The side with sticky is the printing side.

2. Remove the paper, print it on both sides first, and the side with a clearer pattern is the printing side.

A simple way to tell the difference between the front and back of a piece of paper: the rough side is the printing side, and the smooth side is the back.

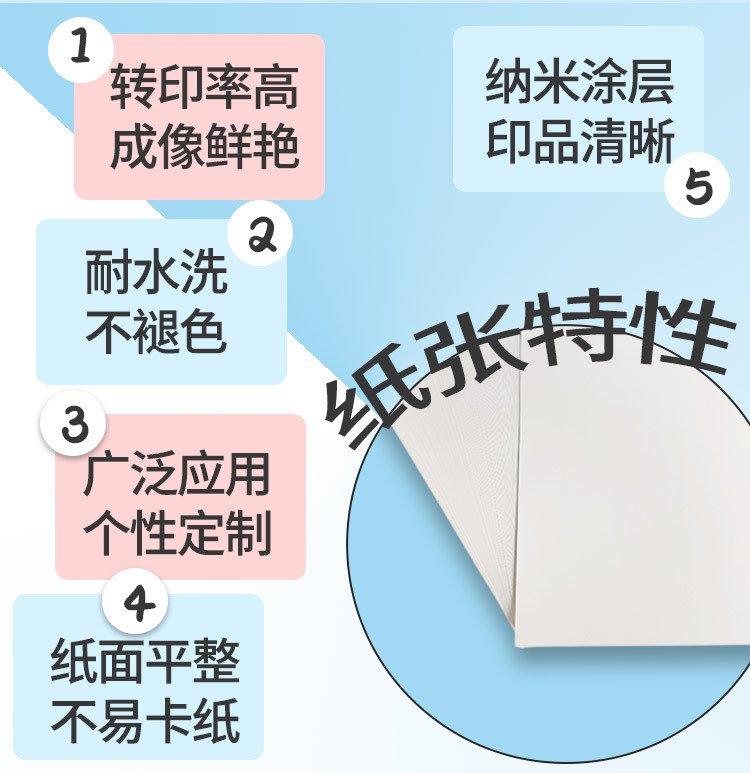

The surface of the paper has a layer, so it will slightly curl when heated. Before printing, bend the paper slightly and then insert it into the printer. The reason why the slow-drying sublimation paper needs to be coated is to prevent the ink from directly contacting the paper (preventing the ink from being absorbed by the paper), so that the ink on the paper can be more fully transferred to the item to be transferred, achieving a more vivid color effect than other papers. The quality of the paper and ink plays a crucial role in achieving a good heat transfer effect.

Special Note:

Due to the slow-drying nature of sublimation paper, it has a special coating on its surface that prevents ink from being absorbed by the paper quickly. This results in a more vibrant color transfer than with standard color inkjet paper, with a complete transfer rate. However, it can also cause printer gears to leave an imprint during printing, with the imprint becoming deeper as the number of prints increases. To alleviate the imprint, one can typically clean the gears with a cotton swab dipped in alcohol or blow cold air toward the paper feed during printing, which can slightly reduce the imprint but not completely eliminate it.

If you are just starting to use sublimation paper, please note that this is a characteristic of sublimation paper and is not a quality issue. Therefore, please bear the cost of return shipping for any returns due to this reason.

Warnings: The paper has a coating that will curl when heated. Please store it in a cool place. If you notice any curling before printing, please unroll the paper and then reinsert it into the printer.

a4

a4

a3

a3