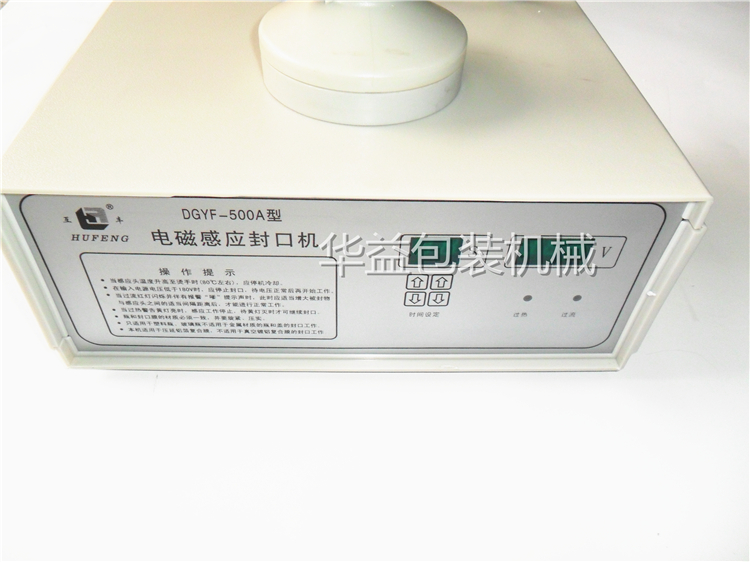

Device Name: Electromagnetic Induction Sealing Machine

Device Introduction

The handheld electromagnetic induction foil sealing machine is used for foil sealing operations of plastic and glass non-metallic packaging containers in the pharmaceutical, chemical, food, beverage, cosmetics, lubricant and other industries.

Handheld electromagnetic induction foil sealing machine is based on the principle of electromagnetic induction heating. It uses high-frequency current to generate a magnetic field through an inductive coil. When the magnetic field passes through the sealing foil material, a large number of small eddy currents are generated instantly, causing the foil to heat up rapidly. The adhesive on the foil melts and complements the sol, thereby sticking to the sealing surface of the container, achieving the purpose of rapid sealing.

The material for the sealing container can be polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polystyrene (PS), ABS, and glass, but it cannot be used for metal bottle bodies or caps.

Device Features

Import single-chip control, high efficiency, low power consumption.

The automatic counting function effectively controls the number of sealings.

Structural design is reasonable,The touch panel is easy and simple to operate.

Automatic heating, over-pressure, and over-current protection functions.

Ultra-wide voltage operating range.

The product performance is stable and has a long service life.

Automatic Shutdown Feature,15 minutes of inactivity,Machine automatically shuts down

Power supply: 220V

Power: 600-1000W (adjustable)

Static current:

Maximum Allowed Power Current:

Shell protection grade: LP21

Working Frequency: 30 kHz (±5%)

Adaptable bottle mouth diameter: 20-130 mm

Crate Size: 46.5*39.5*18.5CM