3, 2 components: tray

8 inch diameter: 12CM heating pad

10 inch diameter: 15.5CM heating pad

4, : baked cap assembly

for printed image in upper brim

5, a small baking mat:

5.5-7.5cm small baking mat

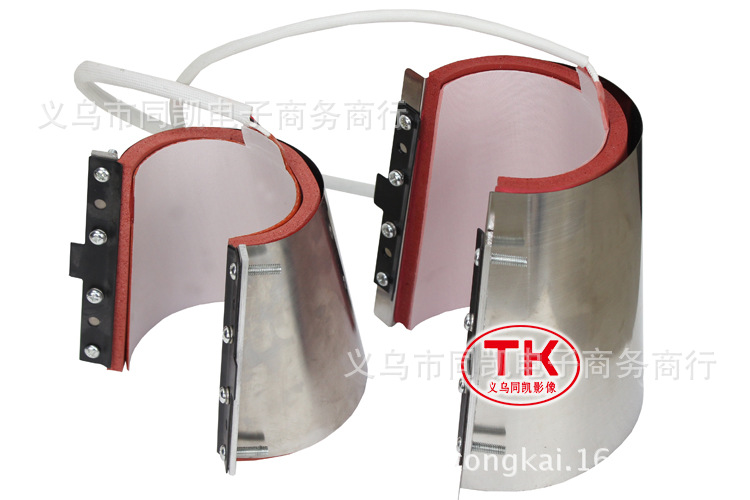

6, 17OZ cone baking mat

7, 12OZ cone baking mat

[show] details

details show... Subtle show real ~..!

[] operating rules

1. Check whether the hot stamping head connection plug is connected with the electric control box.

2. Plug in the power, turn on the power switch. (this machine 220V rated voltage and maximum input power is 1250W)

3. Set operating procedures: (the temperature in degrees Fahrenheit)

starting temperature: according to the mode setting key once, then set the indicator, in addition or subtraction key key to set the starting temperature.

highest temperature: according to the mode setting key second times, then the temperature indicator light, in addition or subtraction key key to set the highest temperature.

The high temperature baking time: according to the mode setting key third times at the time indicating lamp is bright, in addition or subtraction key key to set the most high temperature baking time.

pending status: according to the mode setting key fourth times to enter the implementation of the state machine.

note: initial temperature range of 200-380 degrees, the highest temperature range of 200-430 degrees, the highest temperature baking time setting range 0~999 seconds.

the temperature setting machine with self-locking function, such as the initial temperature is 340 degrees, the machine will automatically limit the set temperature range of 340~430 degrees. On the contrary, if the maximum temperature is 250 degrees, the machine will automatically limit the starting temperature setting range of 200~250 degrees.

: with clean cloth printing plate surface, transfer paper pasted on the surface of the disk, fixed by the high temperature adhesive tape sticky, porcelain heads, placed on the base of foamed silicone rubber plate center, if the pressure is too large or too small, can adjust the height of the head.

[] stamping defect analysis

A. The color is too light: the temperature is too low or the pressure is not uniform or the time is too short.

B. Pattern fuzzy: time is too long lead to ink diffusion.

C. Pattern surface gloss: the pressure is too large or too high temperature.

D . Pattern local fuzzy: hot stamping area of uneven distribution of heat.

E . The pattern has scar: the hot stamping time is too long.

F . Pattern color shades: pressure unevenness or object transfer coating unevenness.

G . Sticky paper: the temperature is too high or the object transfer coating is bad.

parameters recommended starting temperature is set to 230 : degrees, the highest temperature is 330 degrees, the highest temperature curing time is set to 30 seconds.

hot stamping: with a cloth to clean the mug surface, will transfer paper wrapped mug, with high temperature adhesive tape fixed, put in the hot cup machine mold cavity and push the pressure on the handle, such as

pressure is too large or too small, adjustable push rod travel.

: baking cup machine heating pad is not afraid of empty burning, but to try to avoid baking cup body height is far lower than that of roasted Cup Coasters width, the same is also a small part of not only the cup body plug

into baking mat in baking, if in a small part of the cup and bake pattern should be starting in drawing processing.

[] equipment requirements

This set of equipment and supplies stores have sales

India takes the following equipment: cup

In addition to the computer image processing, also need the following things:

1, a machine

2, 6 color or 4 color piezoelectric inkjet printer (advising clients to buy their own local +) even for or empty empty cartridges (the ink is arranged on the inside)

3, sublimation ink (to be installed inside the printer in )

4,high temperature adhesive tape paper sublimation, paper baking cup

5, knife tool

which printer advise customers to the local market to buy Epson R230, printers need after-sales place more, in the local is more convenient. Here are as follows:

[CE] product certification

"CE" logo is a symbol of safety certification, manufacturers as open and entering the European market passport. CE on behalf of the European unity (EUROPEENNE CONFORMITE). Those labeled "CE" logo products can be in the EU domestic sales, not required to meet the requirements of each member country's, so as to realize the free circulation of goods in the EU member states within the scope.