Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Yiwu Jiangzhou Latex Co.,ltd 13yr.

Contacts:Luo Longsheng Chat

Mobile:86-13857964388

E-mail:13857964388@139.com

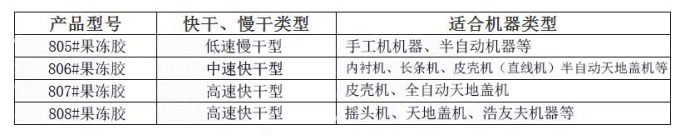

Jiangzhou Brand Jelly Glue is synthesized at high temperature by freezing force 200 industrial gelatin, syrup, food preservative and other raw materials. The product is environmentally friendly and non-toxic, with strong viscosity, good fluidity, fast drying time, no wire drawing, no glue throwing, maintain clean and suitable for leather shell machine, semiautomaton and tiandigai box machine; Jelly Glue due to the low water content, can solve the gift box with book case and post-production is prone to deformation, friable, blistering, mildew phenomenon. Book case, leather phone case, folder, photo album, gift box, shirt box and other products suitable for high-end hardcover books in various printing and packaging industries.

Product features: strong viscosity, moderate drying speed (8-600 seconds), good fluidity. Flexible, environmentally friendly and clean.

Usage: Jelly Glue is a hot melt protein jelly glue, which is applied to the manufacture of printing and packaging, wine box, shoe box, underwear box, shirt underwear box, upscale packaging gift boxes and all kinds of photo album, hardcover book leather phone case, etc, it is suitable for KOUBUS, DEXTER, Shanghai Zihong, Dongguan Hongming, Yiwu Zhenxin and other machinery, and has the characteristics that fast curing speed can improve the hardness of cardboard, it is only applicable to semi-automatic and fully automatic box-making machines with heating equipment high-speed mechanized operations.

Features:(1) strong adhesion, no glue opening, quickly form a layer of dry adhesive film after bonding, which can enhance the stiffness of the packing box, such as uneven surface of base paper, it can make the surface of the bonded paper box or book case more smooth and beautiful;(2) no odor, peculiar smell, non-toxic and harmless;(3) it will not become moldy after sticking, and has strong anti-corrosion ability.

Inspection: This product has passed the SGS test

Shelf life: one year (it must be stored in a cool and dry place to avoid high temperature and sunlight, and the best storage temperature is 18-30 ℃)

Instructions for use:

1. Jelly Glue is a kind of high protein material, which cannot be mixed with other adhesive cement and materials. Long-term exposed storage will lose water, weathering and hardening, making it difficult to dissolve, when using, use a little water to soak the colloidal surface to increase the heat transfer area.

2. When using, you must drive the temperature of the glue machine to 85 ℃ ~ 95 ℃ (the glue machine shows 90 ℃, and the actual glue temperature is only about 75 ℃), only when the actual temperature of the glue reaches above 75℃ can the glue reach the best state.

3. If copperplate paper of 128g or less is used as the packing box, please add less water and thin the glue of gluing machine to avoid too thick glue, which will affect the watermark or foaming on the surface of the box.

4. Different paper and materials have different properties. Please try this product before using it to avoid unnecessary losses. (For example, MDF (medium density fiberboard) board with wax, etc.).

Note: in rainy season, when the air humidity of the production workshop is higher than 90%, use caution (use dehumidifier or moisture absorber to reduce the humidity of the production workshop to less than 70% before using this product). Please put the finished products (boxes) in the moisture-proof warehouse (the air humidity in the warehouse should be kept below 70%) to avoid moisture, foaming and blackening the box.

When the air humidity is higher than 90%, the viscosity of the glue will decrease, and the phenomenon of non-sticking or ungluing will appear. (This problem can only be solved by reducing humidity) when encountering foaming and other phenomena, the glue should be as thin as possible at lamination, and the drying time should be reduced after lamination, and the edge should be covered immediately!

Update time:

TOP