Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Yiwu Tianwei Electromechanical 12yr.

Contacts:Mr.James Chat

Mobile:86-18967986112

E-mail:2924549522@qq.com

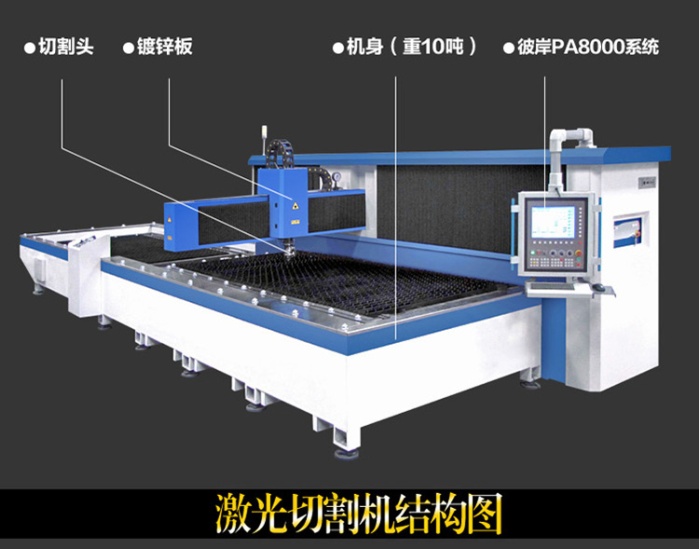

1. TW-F1500 Fiber Laser Cutting Machine

1.The Longmen structure is rational and the operation is stable.

This laser cutting machine features a gantry structure, with casted crossbeams that provide a robust overall construction. It replaces the traditional cantilever design, offering a smaller footprint and lighter weight, with superior resistance to deformation and high precision.

2.High-sensitivity, US-original, imported, following-motion laser cutting head

This laser cutting machine is equipped with a laser cutting head imported directly from the United States, which is characterized by high efficiency, high sensitivity, and a safe and reassuring operation.

3.Touch screen control cabinet

4.Adopting a Japanese Mitsubishi servo motor, it has improved the speed and stability of the cutting process.

XYThe shaft is equipped with two 1-horsepower Mitsubishi servo motors, and the Z-axis follow-up section uses a 200W motor. The combination of these three ensures stability and efficiency in work.

5Combining high-precision motion systems with specialized work platforms.

The motion system uses high-precision ball screw transmission and servo drive system to ensure the high precision of cutting. The tooth-shaped work platform and pressure strips are suitable for supporting the cutting of various metal sheets.

6.High-power chiller, which continuously cools and cools the laser system, automatically regulates the temperature, ensuring long-term work while greatly saving electricity and reducing production costs.

Characteristics

High cutting precision and good stability:

Adopting a precision ball screw transmission mechanism and optimizing the control of the CNC system, it can meet the requirements of precision part manufacturing.

And the dynamic performance is stable, capable of working for a long time.

Good quality of cutting surface.

Adopting the original imported American laser cutting head, the cutting head moves with the height of the board, maintaining the position of the cutting point unchanged, which makes the cut seam flat and smooth. The cross section does not need subsequent processing, and it is suitable for cutting flat or curved panel materials.

Large cutting area, suitable for a variety of cutting materials, and has wide applications.

Metal sheets with cutting sizes within 2500mm×1300mm.

The materials that can be processed include: ordinary carbon steel, stainless steel, titanium plates, etc.

High value for the money

For thin plate cutting, it can replace CO2 laser cutting machines, CNC punching machines, and shearing machines, and the overall cost of the machine is comparable.

Equivalent to 1/6 of a CO2 laser cutting machine and 1/4 of a CNC punching machine.

Low cost of use:

This laser machine uses a fiber laser, with the main consumables being: protective lenses, focusing lenses, ceramic rings, and cutting nozzles. The overall machine cutting cost per hour is between 14-17 yuan. Since it uses a fully imported GSI fiber laser, with direct cable transmission and no flying optical path, it greatly improves product stability and requires no after-sales maintenance!

Cutting speed is fast and high efficiency:

This machine can cut ordinary carbon steel at a maximum speed of 10 meters per minute. With the development of the subcontracting processing industry, the competitiveness of sheet metal processing is increasing, mainly reflected in the reduction of subcontracting costs and the increase in profits. The fiber laser cutting machine with fast processing speed, low operating cost, and no need for preheating when starting up, is undoubtedly a better solution for you.

Subsequent savings in materials and costs:

(1)Graphic automatic correction function. When our processing materials are not placed in a cohesive manner on the work surface, the software will automatically adjust the placement of the graphics within the software area according to the degree of material deviation, thereby ensuring that the processed objects can all be within the processing range, ensuring that no material is wasted and no large amount of labor is needed to place the materials in the center, which greatly saves costs and achieves high efficiency.

(2) This laser machine has a simple structure, easy operation, stable laser performance, and low maintenance costs.

Core Technology:

1The laser is equipped with a British-imported GSI laser; it has stable performance and a service life of up to 100,000 hours.

2、Original imported American laser cutting head with high efficiency, high sensitivity, and convenient operation.

3High photoelectric conversion rate: Fiber laser cutting machines have a photoelectric conversion rate three times higher than that of carbon dioxide laser cutting machines, which is energy-saving and environmentally friendly.

4Low maintenance cost: no laser working gas; fiber optic transmission, no need for reflective lenses, can save a lot of maintenance costs.

5Easy operation and maintenance: Fiber optic transmission, no need to adjust the optical path.

Other advantages: its safety indicator light, automatic exchange of air, oxygen, nitrogen, and purified gas, protection of fiber-optic curves, and the sewage discharge of the ventilation system.

III. Main Technical Parameters and Configuration

|

Serial Number |

Project Name |

Parameter |

Unit |

|

1 |

Laser cutting machine model |

TW-F1500 |

|

|

2 |

Laser wavelength |

1080 |

Nm |

|

3 |

Laser rated average power |

400 |

W |

|

4 |

Laser Injection Power |

1.6 |

KW |

|

5 |

Water-cooled refrigerator power |

0.6 |

KW |

|

6 |

Double-exhaust power |

1.5 |

KW |

|

7 |

Machine tool power |

10 |

KW |

|

6 |

Max Processing Range |

2500×1300 |

mm |

|

7 |

X. YShaft positioning accuracy |

±0.03 per meter |

mm |

|

8 |

X. YAxis Repeated Positioning Accuracy |

±0.01 |

mm |

|

9 |

X. YShaft Rapid Movement Speed |

30 |

meter per minute |

|

10 |

X. YMaximum Cutting Speed of Shaft |

10 |

meter per minute |

|

11 |

Min cutting line width |

0.2the following |

mm |

|

12 |

Max cutting thickness (carbon steel, stainless steel) |

Carbon steel4Stainless Steel3 |

mm |

|

13 |

Adapt to cutting materials |

Stainless steel, carbon steel, titanium plates, etc. |

|

|

14 |

Machine tool overall floor space |

4.0×2.5×1.5 |

M |

|

Serial Number |

型号 |

Name |

Quantity |

Remark |

|

1 |

TW-Fiber-400W |

Laser cutting machine tool |

1set |

Shandong University Luner |

|

2 |

1500w |

Laser |

1set |

|

|

3 |

|

chiller |

1Taiwan |

|

|

4 |

1300W |

Servo motor |

3Taiwan |

Mitsubishi |

|

5 |

400W |

Stable Voltage Power Supply |

1Taiwan |

|

|

6 |

|

High-precision imported gears |

3root |

Taiwan |

|

8 |

|

Control System |

1set |

|

|

9 |

|

Air Compressor |

A machine |

|

Comparison of CNC Punching Machines and Laser Cutting Machines:

CNC punching machine is the abbreviation of Digital Control Punching Machine, which is an automated machine tool equipped with a program control system. This control system can logically process programs specified by control codes or other symbolic instructions, decode them, and then make the punching machine move and process parts.

Compared with CNC punching machines, laser cutting machines have the following advantages:

(1)Capable of processing various complex structures, as long as any image can be drawn on a computer, the machine can complete the processing.

(2)No need for molding, just create the design on the computer, and the product can be produced immediately. This allows for rapid development of new products while also saving costs.

(3The cutting machine has an automatic tracking system, so it can not only complete flat cutting but also complete cutting of various irregular curved surfaces.

(4The complex process requirements of the CNC punching machine are difficult to complete, but laser cutting can do it.

(5The surface is very smooth, and the product level is very high, which is difficult for CNC punching machines to achieve.

(6Molded box body0.5Within 1 meter, additional processing such as holes and grooves is required, which is not possible with a CNC punching machine. A CNC metal laser cutting machine can solve this problem.

The application of laser cutting machines is becoming increasingly widespread, and it is gradually gaining market recognition and acceptance. Nowadays, laser equipment manufacturing enterprises are developing like spring buds, and laser cutting machines will become the development trend of future cutting directions.

Update time:

TOP