Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Yiwu GuoFang kitchenware Co. Ltd. 13yr.

Contacts:Linda Chat

Mobile:86-18058480880

E-mail:1918666888@qq.com

Model

Shape Size

Surface treatment

Material thickness

QN1861

600*400*23mm

Anode

0.6mm

QN1871

0.7mm

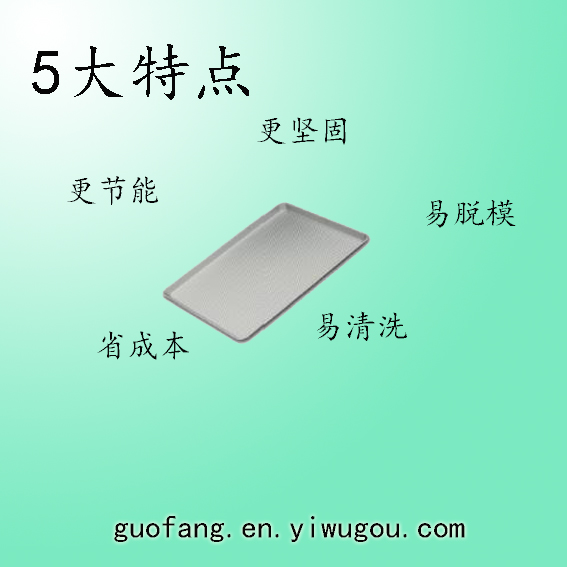

Rhombus eco-friendly and energy-saving baking tray

·Economy Aluminum-Coated Griddle: Made of 0.6mm Aluminum-Coated Sheet

Standard aluminum-coated baking tray: Made of 0.7mm aluminum-coated sheet metal.

· Enhanced Aluminum-Coated Griddle: Made of 0.8mm Aluminum-Coated Sheet

Comparison of Advantages and Disadvantages between Rhombus Eco-friendly Energy-saving Baking Tray and Traditional Baking Tray

One, Compared with traditional baking trays, the rhombus-shaped eco-friendly and energy-saving baking tray significantly increases the bottom heat area of the baking tray in the oven, thereby utilizing more heat to a greater extent, shortening the baking time by about 10% to 15%. This achieves the effects of energy conservation and environmental protection.

Secondly, compared with traditional baking trays, the diamond-shaped eco-friendly and energy-saving baking tray uses its excellent diamond-shaped concave and convex grooves to perfectly apply physical mechanics. It has a diamond-shaped concave and convex craft groove pressed into the bottom of the baking tray, which greatly improves the strength of the baking tray. In use, it significantly reduces the possibility of impact deformation, making it more durable and increasing its service life by one-third compared to traditional baking trays.

III. Compared with traditional baking trays, the rhombus-shaped eco-friendly and energy-saving baking trays have changed the contact between baking products and the surface of the baking tray from a flat contact to a point contact. Therefore, when the baking products are removed from the oven and cooled, the water and heat generated between the baking products and the baking tray are more easily dispersed, which improves the cooling speed. This makes it easier to remove the mold and reduces the problem of adhesion between traditional baking trays and baking products, leading to poor quality products. This significantly improves the production efficiency and the yield of finished products.

IV. Compared with traditional baking trays, the rhombus-shaped eco-friendly and energy-saving baking trays reduce the contact area between the baking tray and the baked goods, thereby reducing the adhesion of the baked goods to the baking tray, which causes difficulties in cleaning. This avoids excessive cleaning of the baking tray and affects the service life of the non-stick coating on the surface. Therefore, it is more cost-saving.

Update time:

TOP