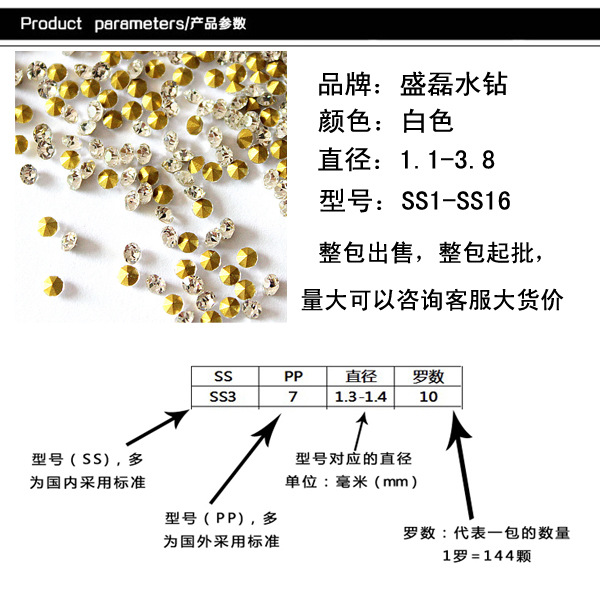

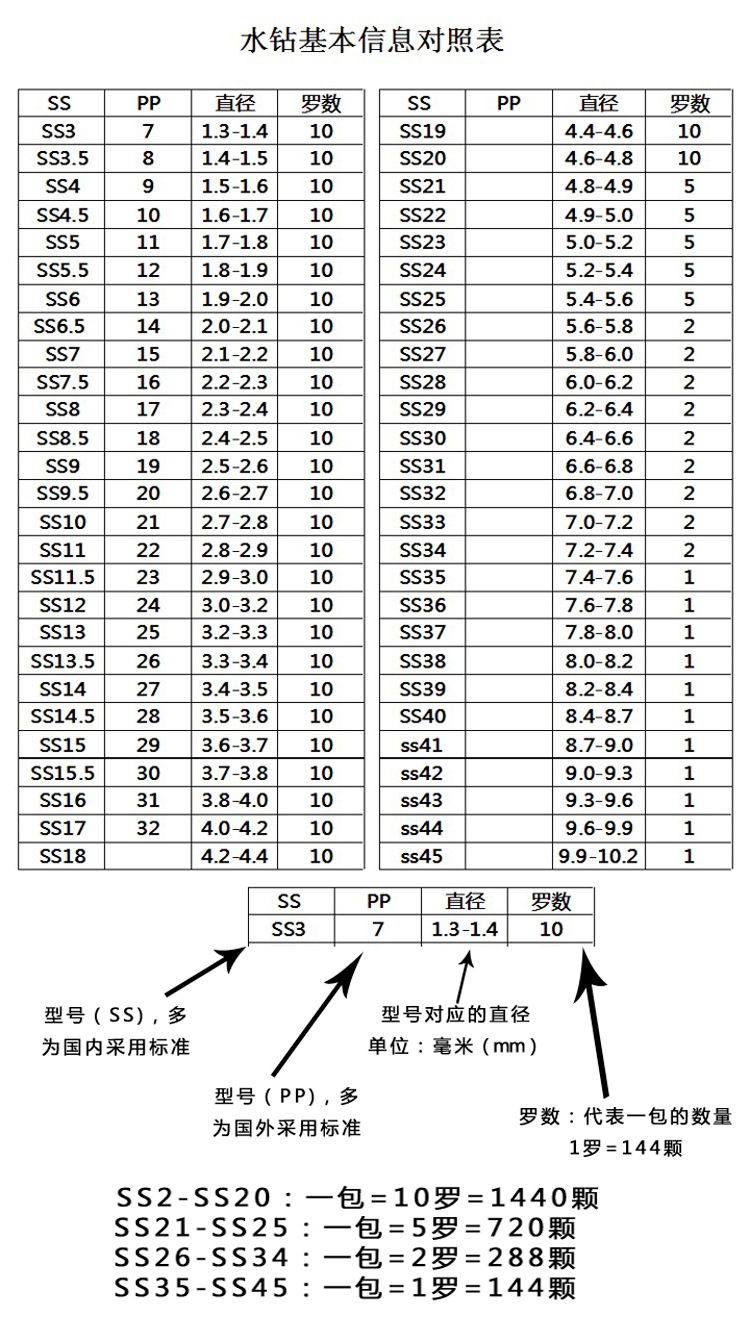

1 Luo = 144 grainsPlease take a photo in multiples of 1440.Quantity-based customers can contact customer service for packaging according to the guest's requirements! Quantity can be more favorable!!! Sales hotline: 15958906848

The production process of water-based diamond

The production of ordinary water-drill is a type of imitation diamond product that is made by melting a high-lead crystalline glass into a round blank, then grinding and polishing it. It is the most common type of jewelry clasp at present.

The usual water drilling production process is as follows:

1. Melting

The furnace must be made with high-quality zirconium steel bricks, capable of holding 0.2 tons or 0.5 tons. It can also be made using other simple methods.

Only after strict quality screening of raw materials and strict formula ratio can high-quality blanks be melted. The blank is at least 25% lead-containing crystalline glass material, which ensures high refractive index and good product quality. Good materials lead to good products.

2. Embryo formation

Glass liquid is molded using a specialized die, followed by processes such as fire polishing to ensure the roundness and consistency of the blanks. The blanks also undergo strict annealing processes to ensure their quality and mechanical properties.

3. Grinding drill

The equipment used in the grinding drill production is all specialized equipment, which is controlled by electronic and electrical automation equipment.

All technical requirements for the tools and fixtures used on the grinding drill equipment, including those for adhesive water drill blanks, are extremely strict. In particular, the precision requirements for the fixtures are relatively high, with the accuracy of the needles typically required to be within 20um.

The adhesive powder used for grinding the water-drilled beads is a special material that each company makes on its own.

The abrasive used for grinding is also homemade, and its process requirements are very strict. Moreover, it is exclusive to a specialized industry. It is worth mentioning that the Yahua Company has independently innovated and developed the process technology of grinding water drills, replacing the traditional way of grinding with abrasive drills.

④ Polishing wheels are used to polish the water drill blank, which has been ground into shape. The purpose is to polish the water drill blank to a shine as bright as diamond. This wheel is made by mixing glass polishing powder and other chemical materials. Currently, each enterprise also prepares its own unique mixture for use.

The usual grinding process is: prepare special clamps -> adhesive on the front surface (adhesive raw beads) -> slant grinding (8 surfaces) -> slant polishing (8 surfaces) -> adhesive on the reverse surface (reverse adhesive raw beads) -> slant grinding (another 8 surfaces) -> slant polishing (another 8 surfaces) -> plane grinding -> plane polishing -> cutting the material.

4. Cleaning

After polishing the water-cooled diamond, it is removed from the adhesive using a proprietary process, followed by ultrasonic cleaning to ensure it is completely free from any contaminants.

5. Inspection

Inspect the grade of the polished water-filled diamonds (now called 'bare diamonds' or 'naked diamonds') and sort out the defective ones.

6. Sieve

Separate the drill sizes by using an automatic sieve machine or manual sifting tools.

7. Absorbent membrane

This is a supporting process, the purpose is to prepare for the next chemical plating process. It is to embed a large number of light drilling bits into a plastic film piece through specialized equipment, which is convenient for batch chemical plating.

8. Electroplating

Plate a layer of silver on the surface of the light drill to increase the reflection ability of the water drill.