X Email Mobile

| Number | Unit-price | Total | |||

| I want to buy: | × | 75.0 | = | 0 |

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Dongyang Joro Technology Co.,Limited 8yr.

Main Products:Card material ,Badge machine and consumables,binding material,plastic film etc.

Contacts:Wang MiaoChat

Mobile:86-15858983008

E-mail: WeChat:JORO_008

Address:Dongyang City,Jinhua City City,Zhejiang Province

Related items

| Product Name | PVC免层压 |

| Size | "200*300mm, A4, A3" can be translated into English as "200*300mm, A4, A3". |

| Product Color | White, gold, color |

| Printing Material Type | Inkjet printing, laser printing |

|

Printing material thickness |

0.15mm、0.25mm |

| Middle material thickness | 0.28mm、0.46mm、0.65mm |

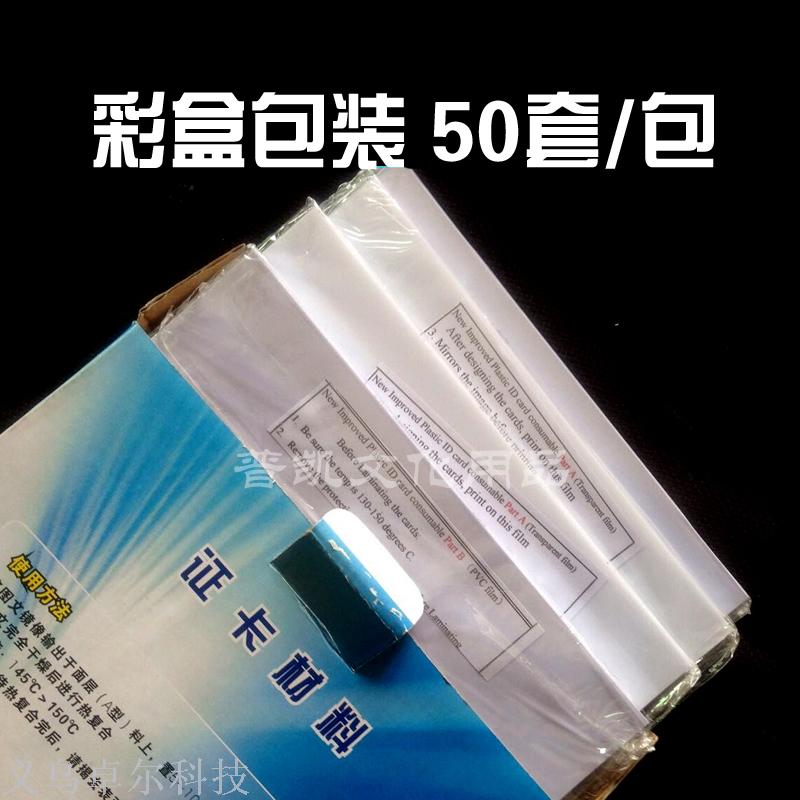

| Packing Specifications | 2 sheets of printing material + 1 sheet of medium material = 1 set, 50 sets per box |

| Single Box Weight | 3.8KG |

| Supporting Equipment | Printer (inkjet or laser), paper cutter, plastic sealing machine, cutting machine. |

1. When printing materials, choose mirror printing.

2. Print side determination: Take out a print material, press on the corner with your fingernail, if it can be peeled off, it is the protective side, and the other side is the print side.

3. Before plastic sealing, remove the protective film from both sides of the middle material (by gently prying at the corners of the middle material, the protective film can be seen). Then, place the middle material between two pieces of printed material, align the corners, and then plastic seal.

Step 4: After the plastic coating is completed and the product card is cut, the final step is to remove the protective film from the printing material.

【Usage】:

Produce ID cards, membership cards, student cards, employee cards, and photo stickers. These are essential materials to carry with you.Anti-UV, vibrant colors,The images and text are clear, the color is accurately restored, the card surface is flat and bright, the card is stiff, the adhesive strength is strong, and the UV resistance is strong.

Simple operation,Just need a printerandA plastic sealing machine and a cutting machine are enough to produce cards with high gloss and clarity.

【Usage Method】:

1. The printing material is semi-transparent with a glossy surface. The printing side is the unprotected side, and the protective film is thin and fluffy, which can be torn by hand. Please tear off the protective film after the card is completed.

2. The middle material is white and opaque, with double-sided protective film. The middle material cannot be printed and does not need to be printed.

3. Use computer software to create the image, and then place the printing material into the printer for mirror printing. Leave it for 5-10 minutes (or dry it). Then, peel off one side of the protective film from the middle material, and align the printed image side (the printed side) with the side of the middle material that has been removed from the protective film. Use a plastic sealing machine with a temperature of over 120 degrees to seal it. If you need to create a double-sided card, repeat the above steps once, and then use a cutting machine to create various shaped cards. After the completion of the production, peel off the protective film from the printed material.

Update time:

TOP