Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

| no. 5 battery 1 | CN¥ 1.0 |

| kx1928 tracing smart car | CN¥ 36.0 |

Direct factory contact in bulk, 15858994086

1 yuan for a battery

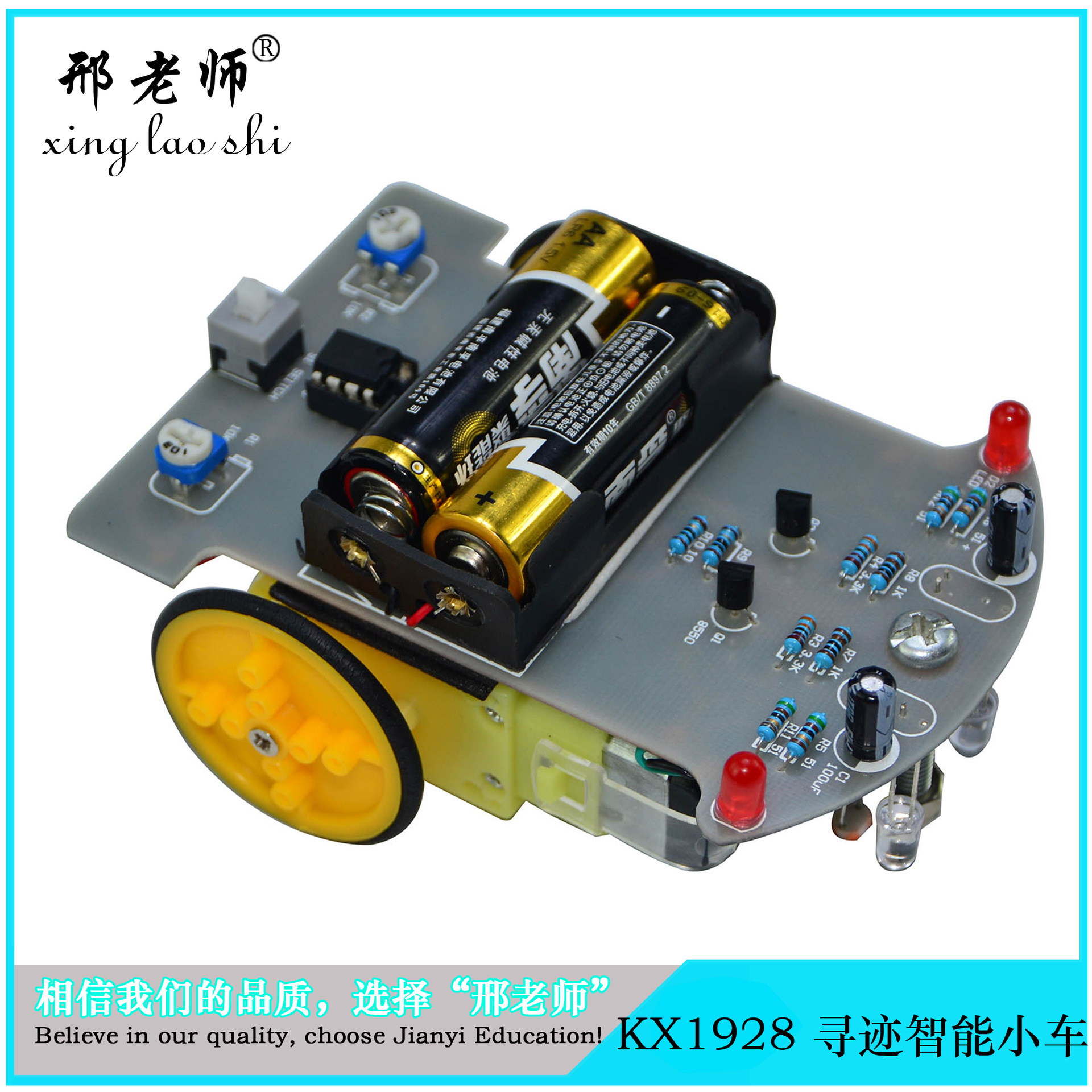

Product Name: KX1928 Tracing Intelligent Car

Product Code: KX1928

Size: 105*87*50mm

Weight: About 160g

Material: Electronic components + circuit board + slow-speed motor + plastic accessories...

Color: Yellow

Is the device powered by batteries? Yes.

Packing: 100 pieces

Box Specification: 600*450*550mm

Intelligent Automatic Tracking Car

With the increasing emphasis on quality education, many schools have made the construction of intelligent cars as their preferred subjects. Intelligent cars are lively and interesting, involving a variety of subjects such as mechanical structure, electronic fundamentals, sensor principles, automatic control, and even microcontroller programming. Students can greatly improve their ability to solve practical problems through hands-on practice, and intelligent cars are also a good hardware platform. As long as some control circuits are added, they can complete subjects such as tracking cars, fire-fighting robots, football robots, obstacle avoidance robots, and remote control cars.

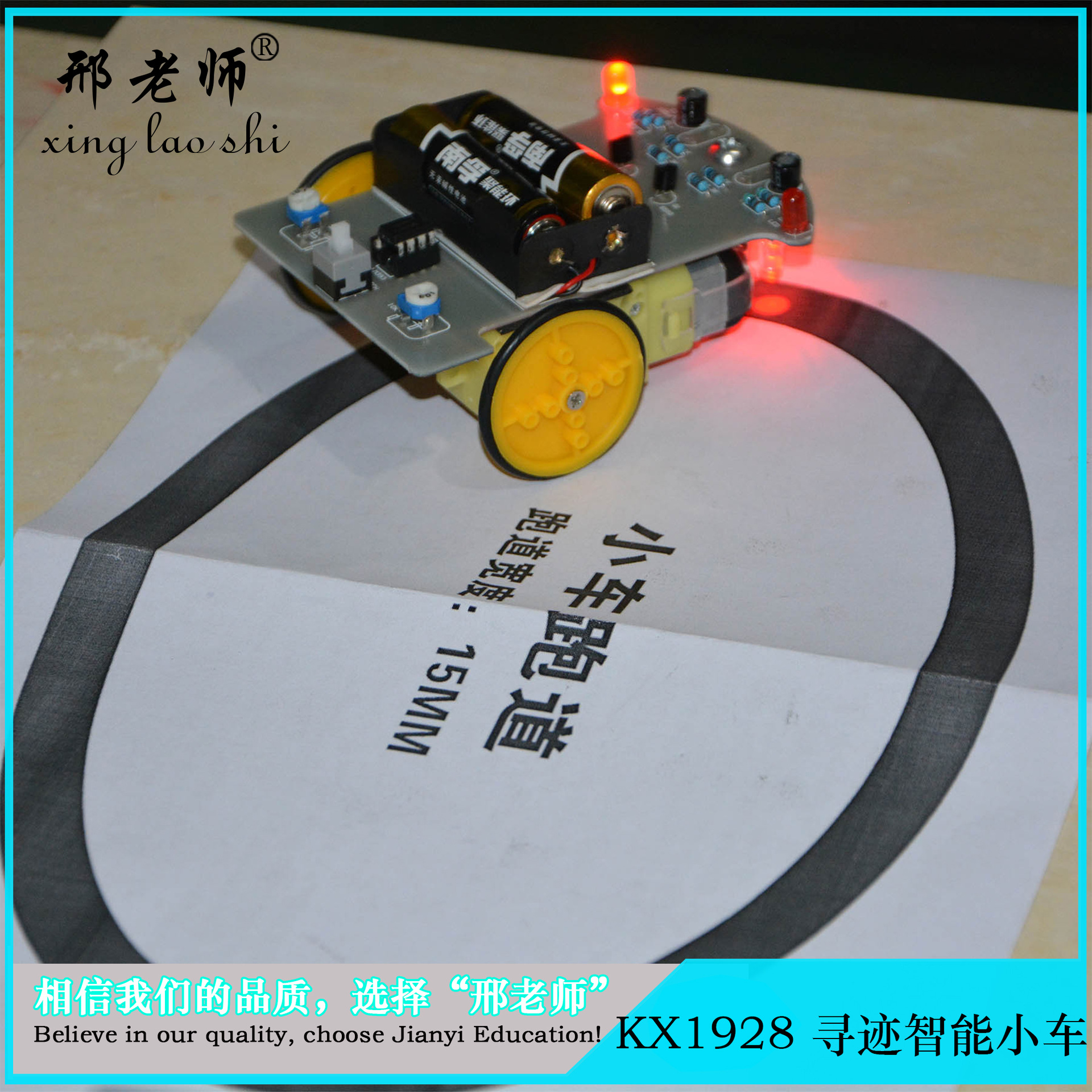

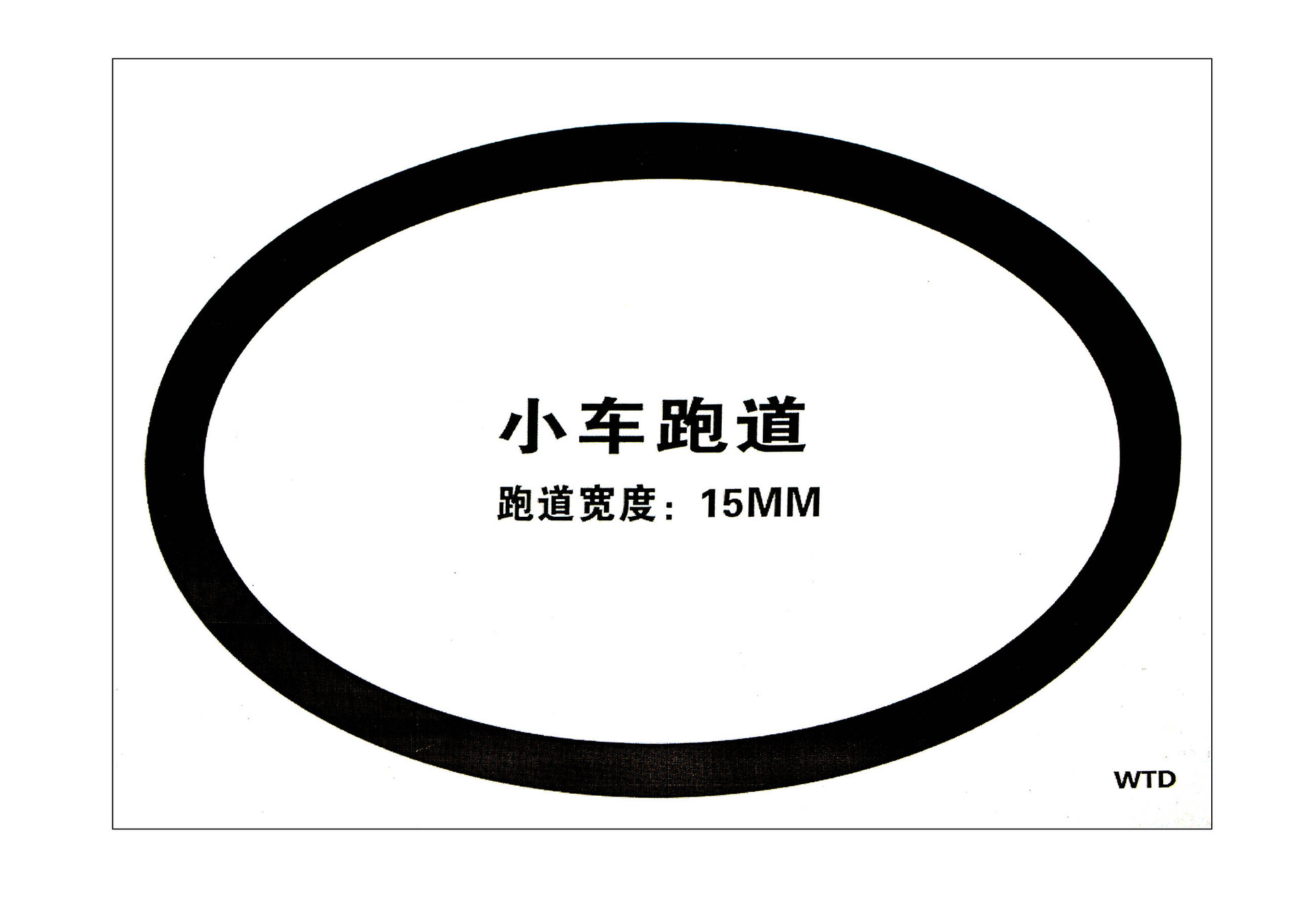

On a white field, there is a 16-millimeter-wide black track. Our tracking car can drive along the black track automatically, no matter how the track bends. It's really amazing! We all know that the reflectivity of light from a white object and a black object is different. Here, we use red LEDs as light sources. When the light reflects from the ground to the photoresistor, we can judge whether the car is driving on the white area by detecting the change in the resistance of the photoresistor. If it detects the black track, it means the car is off track, and the motor on this side will slow down or even stop, and the green LED on this side will go out, driving the car to drive in the opposite direction. This way, the car can always drive along the track.

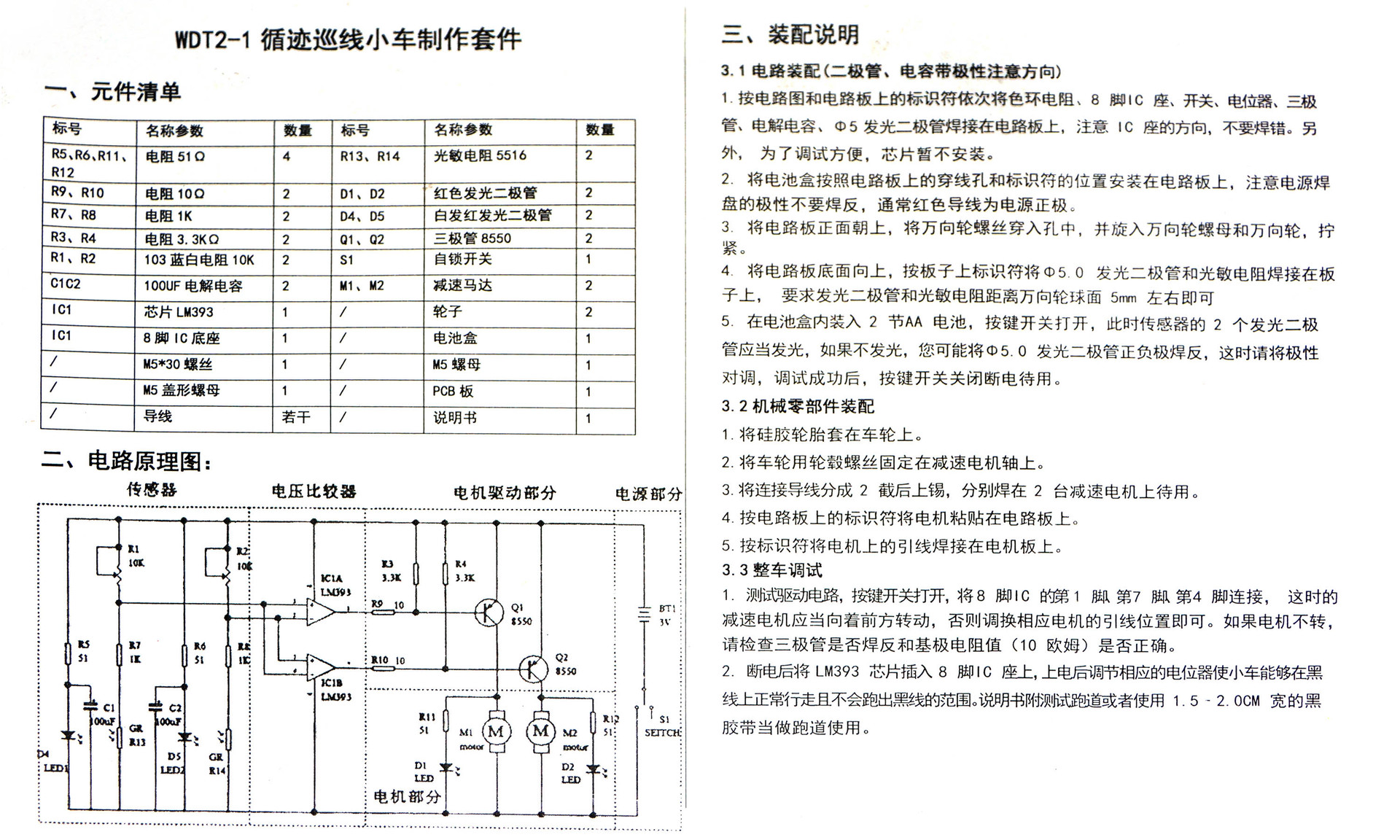

Accessory Diagram:

circuit diagramAdhering to the principle of simplicity to complexity, we will create a smart tracking car controlled by digital circuits. In the assembly process, we not only get familiar with mechanical principles but also gradually learn related electronic knowledge such as photoelectric sensors, voltage comparators, and motor drive circuits.

LM393Comparator Integrated Circuit

LM393It is a dual-path voltage comparator integrated circuit composed of two independent precision voltage comparators. Its function is to compare two input voltages and change the output voltage level based on the relative heights of the two input voltages. The output has two states: it is close to open circuit or is pulled close to the low level. LM393 uses an open-collector output, so an upstream pull-up resistor is required to output a high level.

DC motor with gear reduction

If you drive a car with a DC motor, you must reduce the speed, otherwise, if the rotation speed is too high, the car will run too fast and it will be difficult to control in time. Moreover, without reducing the speed, the torque will be too small to even start moving. The specialized motors we have specially designed have integrated gear reduction, which has greatly reduced the difficulty of production and is very suitable for our use.

Let's familiarize ourselves with the working principle diagram of the entire machine. LM393 is always comparing the sizes of the two photocouplers, and when an imbalance occurs (for example, one side is pressing on the black track), it immediately controls the motor on one side to stop rotating and accelerates the rotation of the motor on the other side, thus causing the cart to correct its direction and return to the correct direction. The entire process is a closed-loop control, so it can quickly and sensitively control.

Step: Basic welding of the circuit portion

The circuit welding part is relatively simple. The welding sequence should be in accordance with the principle of height from low to high. Welding 8 resistors, be sure to use a multimeter to confirm the resistance value is correct. For components with polarities, such as transistors, green indicator lights, and electrolytic capacitors, it is necessary to distinguish the polarity and refer to the component direction in our pictures as much as possible. When welding capacitors, the short lead is the negative pole inserted into the shadow side of the PCB silkscreen. When welding green LEDs, pay attention to the long lead is the positive pole, and the welding time cannot be too long or it is easy to damage the welding. D4, D5, R13, and R14 can be temporarily not welded. The integrated circuit chip can be left out. After the preliminary welding is completed, please carefully check to prevent carelessness.

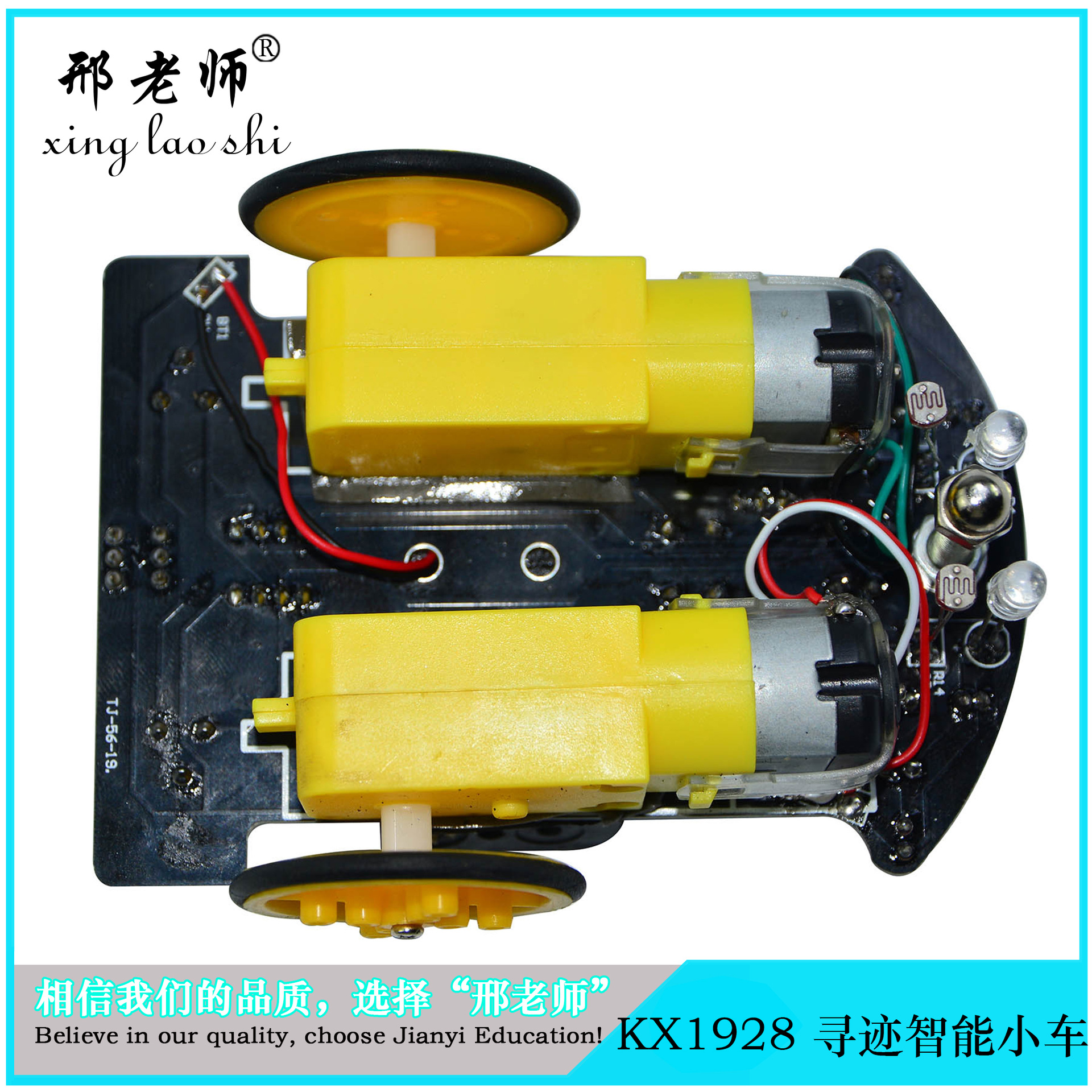

Step 2: Mechanical Assembly

Insert the swivel wheel screw into the PCB hole and screw in the swivel wheel nut and the swivel wheel. Attach the battery box to the PCB with double-sided tape, and solder the lead wires through the pre-drilled holes to the PCB. The red wire connects to the +3V power supply, the yellow wire to ground, and any excess lead wires can be used for motor connections.

Assemble the wheels

The mechanical assembly can be assembled first by assembling the wheels. The wheels are composed of three wheel discs, with the inner wheel disc having a long round hole in the center, the middle wheel disc having a smaller diameter, and the outer wheel disc having a round hole in the center. The three wheel discs are fixed with two screws and nuts, and then fixed to the motor shaft with black self-tapping screws. After that, the silicone tire is fitted onto the wheel. Connect the motor leads with wires, and then paste the wheel assembly onto the PCB at the designated position with the adhesive tape. Pay attention to maintain enough space between the wheels and the PCB edges. Sell the motor leads to the PCB, and make sure to leave the leads long enough, to facilitate the change of the lead sequence in case of a wrong rotation direction of the motor.

Step 3: Install the photoelectric circuit

Photoresistors and light-emitting diodes (note the polarity) are reverse-mounted on the PCB, with a spacing of about 5mm from the ground, and the distance between the photoresistors and light-emitting diodes is also about 5mm. After that, you can power on the test.

Step 4: Vehicle Debugging

Insert two AA batteries into the battery box, and set the switch to the "ON" position. The correct direction for the car to move is along the direction of the universal wheel. If you press the left photoresistor, the right wheel of the car should rotate. If you press the right photoresistor, the left wheel of the car should rotate. If the car moves backward, you can exchange the wiring of the two motors at the same time. If one side is normal and the other side moves backward, you only need to exchange the wiring of the motor that moves backward.

Special Note: The back of the assembly instructions is a simple track for the trackless car. Customers can also directly use 1.5~2.0 cm black electrical tape to paste on the ground to design a more complex track, which is more fun.

The exciting intelligent car race was held.

The preliminary round was staged in the laboratory.

This is a competition that integrates innovation, practice, knowledge, and fun.

The students all took out their carefully made cars.

Prepared to fight it out with the opponent.

How can I make the car go faster?

How to make the car route more accurate?

The contestants have already gone through continuous practice and improvement.

Improving and enhancing the performance of the intelligent car

With unremitting efforts and team collaboration

Make the car run on the track.

According to the established route, track racing

Challenge oneself with unwavering confidence.

Unfolding the drama of 'Speed and Passion'

The intelligent car moves forward and turns on the track.

Step by step towards the predetermined destination

Carrying the beliefs and efforts of the competitors, they race on the track with speed.

The competitors' cars are all unique in their own ways.

They all harbor the perseverance and passion of every competitor.

Come and take a look at the little cars that have been beautified by appearance.

Zhejiang Jianyi Education Technology Co., Ltd.

Zhejiang Jianyi Education Technology Co., Ltd. (formerly Yifei Toy Factory)Established in 2007, the current brand "XING TEACHER" and "JIAN YI". Over the past 10 years, our company has made unremitting efforts to make the enterprise gradually mature; Our company is a member of the Ministry of Education Teaching Equipment Industry Association, a backbone enterprise of Zhejiang Province Teaching Equipment, and the company has been awarded the "Heavy Contract and Credit-Keeping" unit for three consecutive years by Jinhua City. In 2014, it was awarded the "Jinhua Teaching Instrument Industry Advanced Collective" by Zhejiang Province.

Zhejiang Jianyi Education Technology Co., Ltd. is a high-tech enterprise that integrates modern scientific research and development of educational equipment, curriculum design, teaching resource integration, and technical services. Zhejiang Jianyi Education Technology Co., Ltd., with high-tech products and modern educational equipment, has established itself in the education industry. Our products are sold all over the country and have been exported to Europe, America, Japan, and South Korea. After years of accumulation, the company has begun to take shape. In terms of technological innovation, the company has professional design personnel engaged in the research and development of complete sets of educational products and the upgrade of existing products; in production, management, and installation services, the company strictly implements the ISO9001 international quality assurance system standards; in marketing, the "Xinglaoshi" products have been entered into many provinces and cities in the country and enjoy a good reputation; for many years, it has provided high-quality, advanced, professional series of modern teaching equipment and professional equipment research and development custom services for the education industry. With excellent, high-quality professionals and perfect after-sales service quality, the company has established a good corporate image. The "Xinglaoshi" educational physics series, chemistry series, photovoltaic, wind energy, geography, biology, art, and other products have been successfully bid for many times in the education bureau tenders. Zhejiang Jianyi Education Technology Co., Ltd. will continue to adhere to the business philosophy of "quality is the best, service is the most diligent, and being honest in life," and adhere to the development policy of "Xinglaoshi" culture, brand, and career. To provide excellent equipment and high-quality services for school teaching and research.We are willing to work closely with new and old friends at home and abroad, join hands to move forward, and devote our utmost efforts to serving education and contributing to educational causes.

Before assembling, please check if the circuit is unblocked and all the components are complete. Ensure that all contact points are in good contact. During the assembly process, be careful not to get glue on your clothes or skin. Keep the parts out of reach of younger siblings to prevent them from swallowing them by mistake! Do not play with them on your head, to avoid the model falling and injuring you!

Update time:

TOP