Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

Search history

Clear allSearch by image

XDrag and drop an image here or upload an image

Max 5MB per image

UploadSign In | Join

X Email Mobile

Yiwu GuoFang kitchenware Co. Ltd. 13yr.

Contacts:Linda Chat

Mobile:86-18058480880

E-mail:1918666888@qq.com

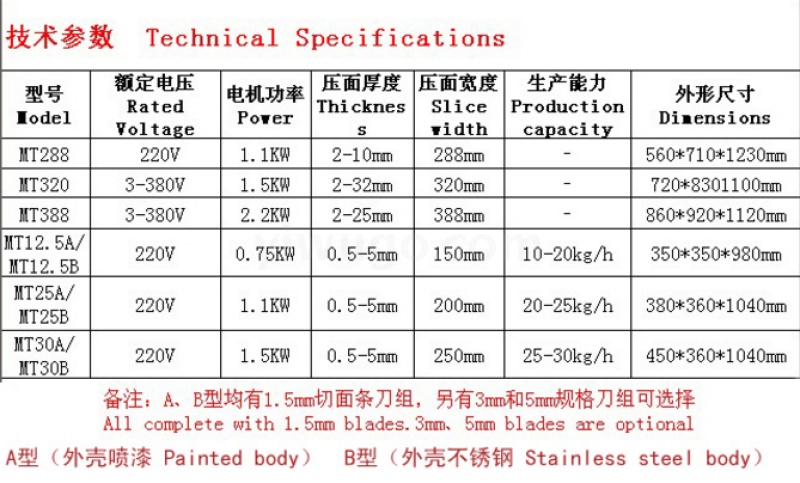

Product name: Noodle Press Machine

ModelMT-30(Standard Edition)、Spray Painting

Rated Voltage: ~220V

Motor Power1.5kW

Production Capacity25~30kg/h

Shape SizeSize: 450x360x1040mm

[Main Features"]

1The series of noodle machine has advanced structure, beautiful appearance, convenient operation, and high working efficiency. It is particularly suitable for the processing of noodles in hotels, restaurants, food processing plants, etc.

2All parts of the machine that come into contact with food are made of high-quality stainless steel (or other materials with special surface treatments), which are hygienic, durable, and meet food hygiene standards.

3equipped with1.5mmNoodles cutting set, and others3mmand5mmSpecification knife set can be selected.

[Use and Maintenance"]

1Check if the power supply voltage matches the voltage used by this machine, and ensure that the electrical connections are secure and the grounding is good.

2Turn on the machine by plugging the power cord into an electrical outlet and pressing the switch.

3Before using the machine, check it to remove any dirt. Apply a small amount of cooking oil to the rolling surface and cutting blade. Solid lubricant (such as grease) should be regularly added to the gears and bearings.

4The slicing knife is composed of a pair of rolling slicing rods, and the width of the slicing knife provided at random is1.5mm,Users can select other specifications of cutting knives as needed.Please provide the Chinese text you want to translate, and I will translate it into English for you.This factory can provide1and1.5and2and3and4and5mmVarious specifications.

5Pressing Operation: Remove the pair of roll cutting knife. Turn on the machine, place the kneaded dough on the feeding plate and introduce it between the rolling rolls, pressing from thick to thin repeatedly. Due to the use of a new type of chain wheel transmission in our factory's pressing machine, the thickest pressing thickness can reach 10mmTherefore, users can adjust the thickness according to their own requirements.

6The operation of cutting the noodles: Adjust the gap between the rolling rolls to the required thickness, install the pair-rolling cutting knife, turn on the machine, and introduce the dough into the cutting device to cut the noodles.

7When pressing the dough, if you find that the pressed dough piece is locally bent or has an uneven surface, the reason may be:

aThe scraping blade at the bottom of the mixing drum under the dough rolling roller is accumulated with dry and hard flour, which should be stopped to clean.

bThe pressure roll is not tightly attached to the mixing barrel knife, causing flour to stick to the pressure roll. The machine should be stopped to adjust. Adjustment method: remove the front roll knife, which is the roller and scraping knife, to check if the place where the roller scraping knife is tightly attached to the pressure roll is flat and smooth. If there are uneven places, the roller scraping knife should be removed and polished with fine sandpaper until it is flat and smooth. After cleaning, the front pressure roll should be installed back, coated with cooking oil, and adjusted with the adjustment screw to test if the pressure roll has spring back.

CIf the roller blade has been worn or damaged, it should be replaced.

8When cutting the surface, there is a phenomenon of not smooth flow:

aCheck if the gap between the rollers for pressing the dough exceeds the thickness of the cutting blade, and if so, adjust it to the appropriate thickness.

Update time:

TOP