X Email Mobile

| EXW Price: |

The price for this item is to be negotiated. Please contact supplier for further information.

|

|

FUFU TRADE 3yr. |

|

| Main Products: |

waimao |

| Contacts: | gongpinChat |

| Mobile: | 86-13751005536 |

| E-mail: | 1919899277@qq.com |

| WeChat: | 13751005536 |

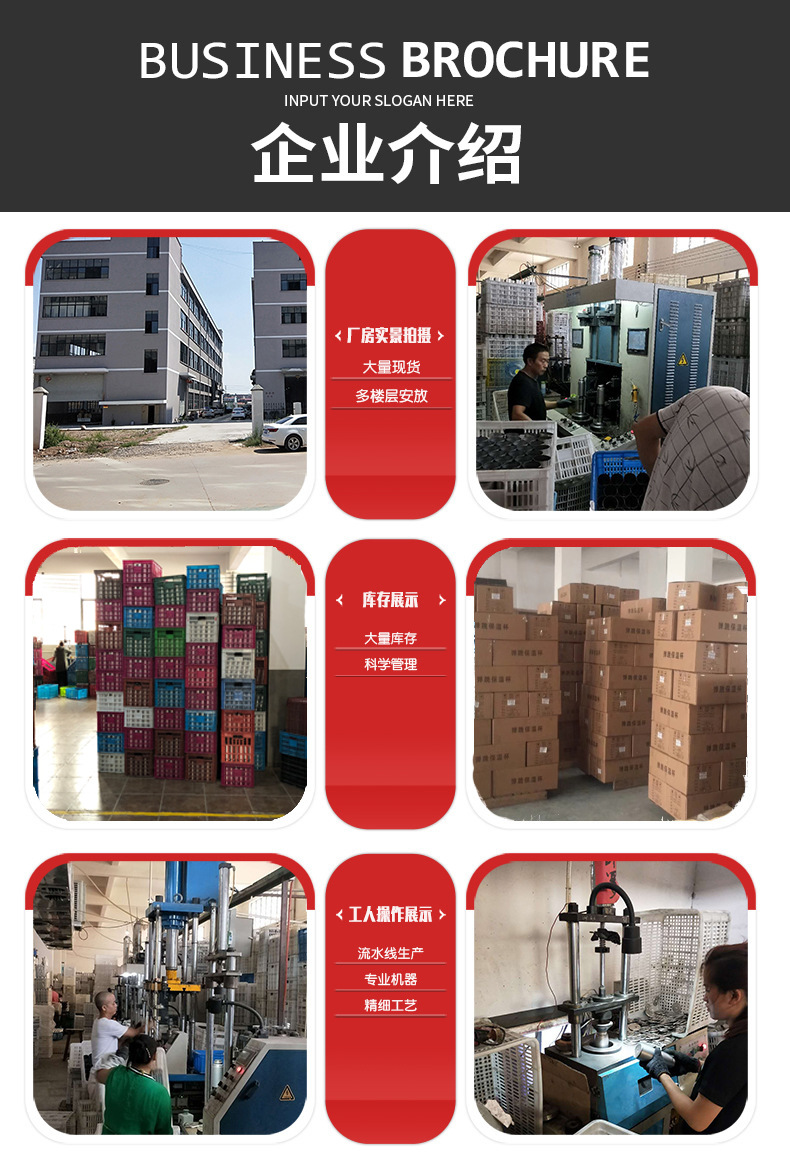

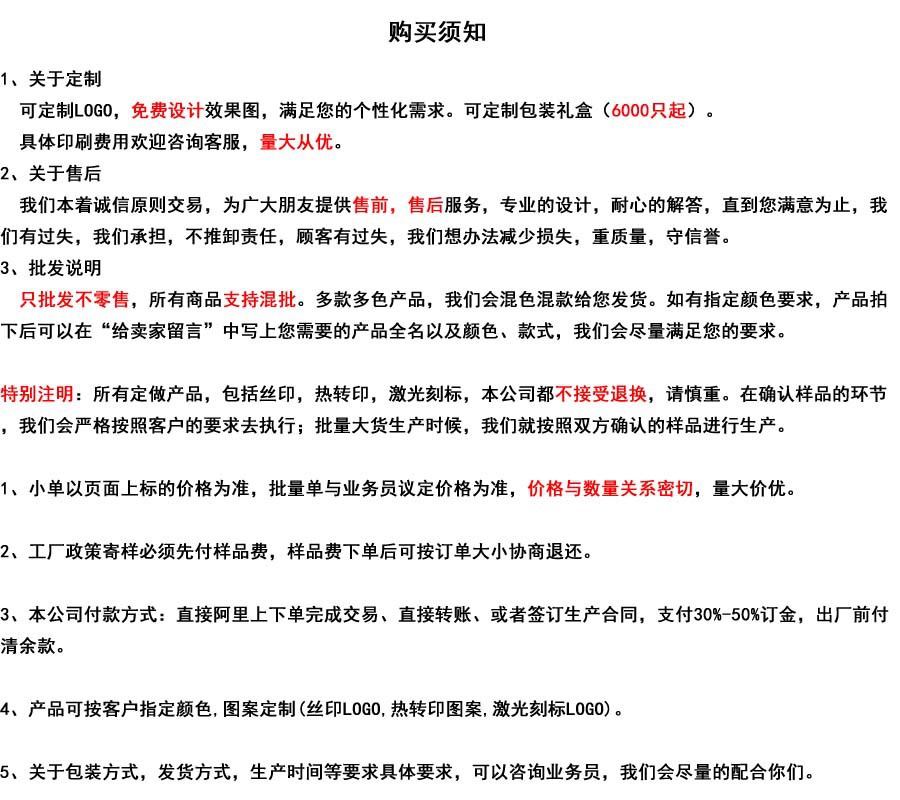

Product Introduction:

name: 316 smart insulation Cup

capacity/size: 500ML/23 * 6CM

performance: heat and cold insulation 12 hours

packing quantity: 50/box

carton size:73*37 * 28CM

purpose: advertising gift customization, cross-border sales, and order delivery

this cup is vacuum cup and heat preservation duration is about 6-12 hours. It is positioned as a gift. If you have quality problems, please contact customer service to return it!

Wholesale profit margin, thank you for understanding!

50 custom logos!

Silk Screen/laser marking is a customized product and cannot be returned or exchanged!

Group purchase printing and laser marking. Welcome new and old customers to customize!

Related knowledge of thermos cup:

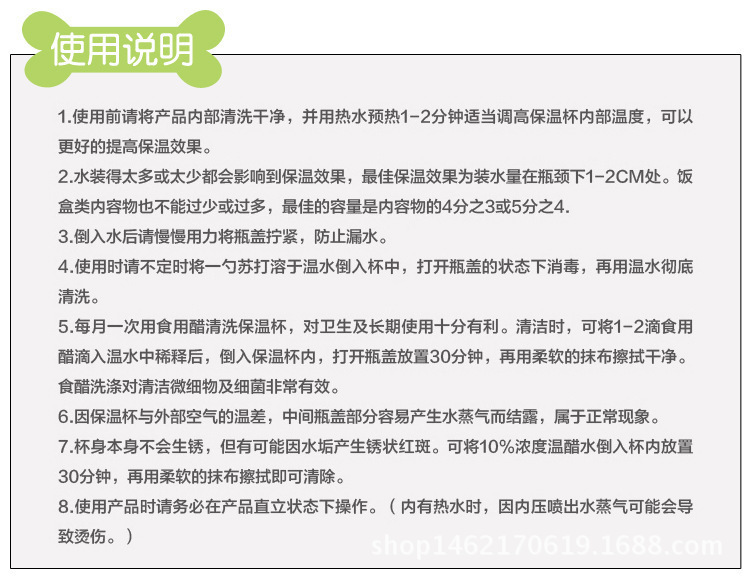

1. Why can't the temperature I tested reach the heat preservation effect or cold preservation effect marked on the page

answer: The heat preservation effect or cold preservation effect changes with the change of the Test environment.

The test conditions for the heat preservation effectiveness or cold preservation effectiveness we have marked are as follows:

the heat preservation effect refers to filling the hot water with water temperature above 95°C to the lower end of the middle Bolt at room temperature of 20°C, and placing it to the water temperature after testing hours under the condition that the product is erected without wind.

Cold preservation effect refers to the water temperature after filling the cold water below the water temperature of 4°C to the lower end of the bottle mouth at room temperature of 20°C and placing the product for 6 hours.

2. The picture looks at the thermos cup of almost the same size, why is the real thing so small or so big.

Answer: The picture is not displayed at the ratio of 1:1, so please bring your own ruler (necessary for online shopping) before purchasing, and compare the size. Instead of judging the size by feeling. In order to avoid the trouble caused by unfit oneself.

The size and weight provided by our store are different depending on the measurement method. It is not excluded that there is a difference within 3cm from what you measured.) if there are fine requirements for the size, please go to the mall counter to have a look at the actual product, then decide to buy.

3. Plastic parts have sudden starting point, linear shape, corrugated shape, or concave small point, like a small scar, I think it is a fault!

Answer: This kind of problem is the requirement of injection mold process, and the purpose is to facilitate demoulding or injection molding of this part. Each product will have it, but it may be different in size or degree. (There are no two identical leaves in the world. But as long as it is the same parts, it will definitely be available. It has no effect on quality. If you do not know this, please do not buy it.

4. Plastic parts are buffing patterns, grinding defect, I am bought as crafts, which is unacceptable at all?

Answer: due to the particularity of plastic, slight grinding may cause slight marks during production and assembly, manual packing and long-distance transportation. (You can use your nails to slightly scratch them to see if there are traces even gently) so if such parts really have some problems, they will not be regarded as defects. Please make a detour for those very picky and neurotic buyers.

5. Why is my size and weight different from yours?

Answer: The size and weight are different, and minor errors are not excluded.

6. There is a friction sound when the lid is tightened. Why?

A: When the lid and cup are tightened, it will definitely make a sound due to friction. It is the same when you buy it in the mall. Please be careful if you are too sensitive.

7. The paint on the mouth of the Cup is not sprayed, is there something wrong?

Answer: the colored spraying of the thermos cup may be uneven at the transition of the Cup neck. The process and technology cannot be achieved, which is a normal situation.

8. Why is there a gap between the lid and the Cup?

Answer: it is normal that the sealing ring between the cup and the lid is not very uniform due to the elasticity of the cup lid. It is the same when you buy it in the mall.

9. Why does the outside or the side of the inner container seem to have a trace of bulge or depression? Some products have slight scratches?

A: Many Cups are not formed at one time. Some can be stretched directly, and some need welding. The mark you see is weld Mark or seam, which is a technical need. In fact, stainless steel is also fragile. It may cause traces when it comes to collision, scratch and scratch. Products go through many processes from production to consumers, including assembly, packaging, transportation, shelving, etc. In so many processes, it is inevitable that some buffing patterns will be received, it is a very normal phenomenon. If you don't believe it, you usually go to the counter or supermarket to see the products. In fact, there are all products, but everyone has higher expectations for online shopping. I hope everyone can treat this kind of phenomenon correctly and don't pursue perfection too much. We guarantee that the products are genuine, but they are better than those in counters and supermarkets, and the price is more affordable.

10. Why there are some small lines, small marks or trachoma on the surface of stainless steel? I don't want any flaws.

Answer: The stainless steel plate itself has its own plate texture when rolling the plate, but some can be disposed when polishing, but it is not excluded that there will be a little left; in addition, stainless steel is subjected to various stresses or other reasons during the stretch forming process, which will also cause the stretch lines of the product (at the same time, in the form of expansion, modification or rolling and folding, the incision will also cause more or less small lines. If it is impossible for you to have cups or stainless steel products with no lines or trachoma at all, these problems will always be found.

11. Why are some cups not very round, with one or several positions slightly inward or outward, or wavy lines

answer: Some Cup ports are single-layer stainless steel design (not double-layer or curling design). Generally, the thickness of stainless steel for thermal insulation products is about 1.3mm. If single-wall Cup ports flash after cutting, during grinding and polishing or other processes, it may cause slight (very slight) deformation than other double-layer Cup ports, as long as it does not affect the appearance and use, it is considered qualified and can be delivered. (If we find that products with serious problems and obvious problems will not be shipped.)

12. Why do spray paint products sometimes have one or two points not sprayed or the bottom edge of the cup mouth is not very neat? Why do some products with patterns have traces around the LOGO and patterns?

Answer: The painting process is actually very complicated, not as simple as imagined. Sometimes the spraying is not very uniform, which will cause this situation. If one more point is sprayed, more paint is sprayed or one less point is sprayed,. But obviously, we will not ship the goods, and minor situations are considered acceptable. In addition, the drinking water position of the Cup is not painted, while the lower position is the closing position of the spray paint, where it is difficult to fold the edge, but after the lid is closed, it can completely cover the invisible, which is the limitation of technology.

Some product logos or patterns are decal paper for heat mark, decal paper most of the time they are posted by hands. Manual products may not be very docile or uneven, it will cause a small folds or slight dislocation when the product is printed. In addition, stained paper will leave stained paper marks after tearing. It's just that some factories with mature technology may do better to deal with this problem. Please don't be too demanding.

13. Plastic parts have sudden starting point, linear shape, corrugated shape, or concave small point, like a small scar, I think it is a fault! Answer: This kind of problem is the requirement of injection mold process, and the purpose is to facilitate demoulding or injection molding of this part. Each product will have it, but it may be different in size or degree. (There are no two identical leaves in the world. But as long as it is the same parts, it will definitely be available. It has no effect on quality.

14. Plastic parts are buffing patterns, grinding defect, I am bought as crafts, which is unacceptable at all?

Answer: due to the particularity of plastic, slight grinding may cause slight marks during production and assembly, manual packing and long-distance transportation. (You can use your nails to slightly scratch them to see if there are traces even gently) so if such parts really have some problems, they will not be regarded as defects. Please ask those very picky or perfectionists to detour.

TOP

Items have been added to the Inquiry Basket

There are items in the inquiry basket