X Email Mobile

| EXW Price: |

|

| Main Products: |

Sealer |

| Contacts: | Mr. LiuChat |

| Mobile: | 86-19143507753 |

| E-mail: | 729939084@qq.com |

| WeChat: | 19143507753 |

| Address: | 15316A, 5 Street, 2 F, 43 Gate, International Trade Mart (District 2). |

GK9 sealing machine hand sewing machine

i. Scope and performance of sealing machine:

larger factories and warehouses are suitable for sealing canvas bag, sacks, flour sack, woven bags and paper bags of grain, sugar, salt food, chemical fertilizers, chemical products, etc.

The single-line chain stitch sewn by this machine has the advantages of beautiful appearance, firm sealing, elasticity and convenient unpacking.

II. Introduction to sealing machine structure

GK9 type sealing machine has compact structure, simple adjustment and convenient maintenance. Screws and nuts are standard parts that are easy to purchase in the domestic market. The shell of the machine adopts a new technology of aluminum alloy die casting, which has good mechanical properties.

III. Three major technologies

|

parameter |

numerical value |

|

model |

GK9 |

|

|

|

|

Needle pitch |

adjustable |

|

suture specification |

standard wraping string |

|

motor Power |

90W |

|

|

|

4. Sealing machine usage and adjustment methods:

bag-sewing machine operation method: Bag-sewing machine the operation method is simple, as long as the thread is worn well, lift the machine to align the bag to be sewn, push switch can be used for sewing.

(1) exchange of sewing machine needles

(1) when turning the hand wheel clockwise to make the sewing machine needles rise to the high position, use8x 10 mm double-headed wrench twist the pine needle clamp nut to pull out the sewing machine needles. When replacing the new sewing machine needles, you must pay attention to the direction of the needle. Its trunking is outward, the gap is inward, and the sewing machine needles nut should be tightened after sewing machine needles is inserted into the top of the needle bar cell tweezers.

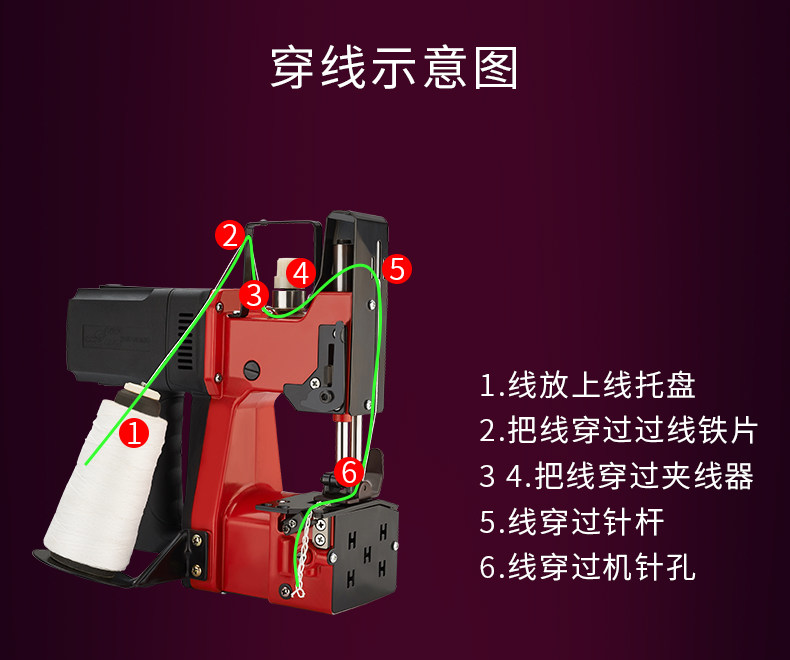

(2) threading procedure

pull out the thread ends in the wire frame online cylinder, pass through the thread a hole and B hole on the back of the machine, bypass crimp terminal, then enter the C hole, pass through the small hole at the tail of the needle bar, and face down along the panel, sewing machine needles pinhole is inserted from the front of The Wire slot of the needle, and it cannot be pulled out90~100 mm thread ends can be sewed.

(3) line specifications and line selection methods

the machine is used according to regulations.21S/12~18 for fibers such as Strand cotton or nylon thread, the suture must be wound on a tapered spindle. After putting the protective line cylinder, fix it with a tailor's tack cap, but no matter what kind of fiber is used to spin the thread, it must meet the following requirements to ensure its proper sewing performance. It is hoped that users will pay attention to the selection of sutures.

1. The suture should be continuous and uniform in thickness without scarring and knot.

2. Soft and smooth surface, no wool, and must have certain toughness and tension.

3. Even twist cannot have large twisting force.

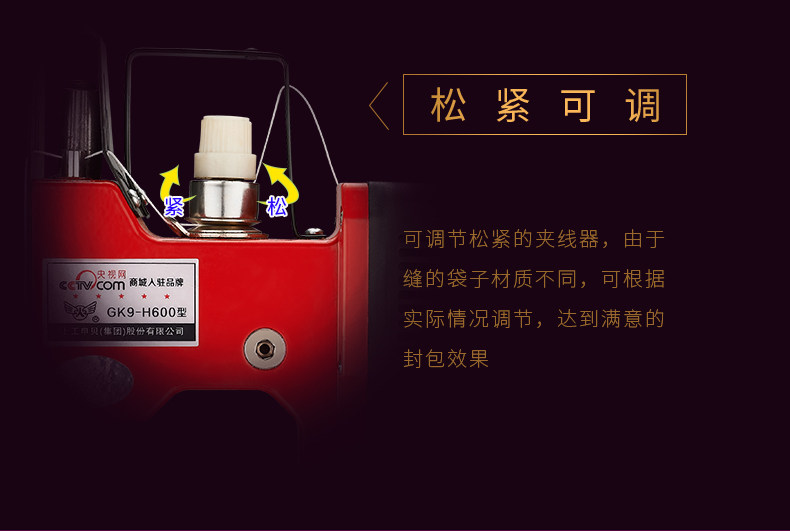

(4) pressure adjustment of suture

the pressure of the suture is the main factor affecting the tightness of the stitch. If the pressure of the suture is too weak, the thread chain after sewing will be relaxed and weak. The bag mouth after sealing is prone to loopholes. If the suture pressure is too strong, it will make the bag mouth crepe due to the lack of elasticity of the thread chain. When it bears a large impact force, it will crack thread chain and generate loose bags.

The principle of suture pressure adjustment should reduce the pressure on thick and tight seam materials and increase the pressure on thin seam materials. When the suture pressure needs to be increased or decreased during use, just tighten or loosen the thread pressing nut on the back.

V. Correct position of sealing machine sewing machine needles and crochet

whether the mutual position of sewing machine needles and crochet is correct or not directly affects the sewing performance of the machine, and the mutual movement and coordination of sewing machine needles and crochet are improper. Serious faults will be caused in sewing performance.

1. When sewing machine needles drops to a low point, the distance between the crochet tip and the center of sewing machine needles is about3.5±0.2 MM

2. When crochet hooks into the coil thrown by sewing machine needles, crochet plane close to the notch plane of the sewing needle, its gap is0.1~0.18 between millimeters, the distance between the lower part of the crochet tip and the upper part of the machine needle hole is2~2.5 MM. The distance from the top of the crochet tip to the bottom of the needle plate is2~2.5 MM

3. Crochet stops on the right, sewing machine needles when falling into the coil of crochet needle, the center distance between crochet back and sewing machine needles is1.5±0.2 MM

six. Sewing machine needles and hook position adjustment method of mutual position

(1) the top of the head is generally from the bottom of the needle plate2~2.5 about mm, when Hook hex head screw(65) loose, you can put crochet on it move down, to be adjusted, the inner six screws must be firmly tightened..

(2) crochet and sewing machine needles mobility, when the gap is too large or sewing machine needles is touched, can be screwed loose hex nut and hex nut to screw the slotted set Bolt in or out a little. Can reduce or increase its gap, when the adjustment is completed, Hexagon nut must be locked firmly..

Seven. Adjustment method of feeding tooth height

the height of the needle plate plane exposed by the feeding teeth is determined by the nature and thickness of the seam material. Seam sealing two layers of linen or quite thick pockets, usually showing the needle plate plane1.5~2 MM. After the tooth tip of the feeding tooth is worn out, it often leads to abnormal feeding. When repairing the tooth tip or changing the new feeding tooth, the height of the feeding tooth exposed to the needle plate plane should be adjusted.

Method of adjustment: turn the handwheel so that the feeding teeth can be loaded into dental rack at the high position of the Cam at dental rack, and screw on the screws to expose the tooth surface of the feeding teeth.1.5~2 millimeter, then tighten the screw hard.

VIII. Line cut thread chain:

to prevent loose threads, when the seam is sealing bag bag, the two ends of the bag should be left separately.50 mm thread chain. To prevent thread chain from spreading out or being pulled out

after sewing a bag, continue to draw out the thread chain, and cut the braid on the cutter to make it long before sewing.50 mm thread chain.

IX. Sealing machine switching method on electric brush motor:

the motor needs to be checked once a month, pay attention to electric brush wear, wear to electric brush8 about mm (long

2/3) new electric brush should be replaced to prevent armature damage. If there are black marks on commutator, yes O no. Sand skin gently sand but must keep commutator of the garden. After disassembly and assembly, inject some sewing machine lubricant into the bearing.

It is relatively easy to change the motor electric brush. As long as the bulkhead screws on the rear side of the motor are turned out, the electric brush can be changed. When checking commutator and bearings, remove the handwheel at the back end of the motor and then disassemble the end cover of the motor.

X. Sealing Machine safety and maintenance knowledge

safety precautions:

since the machine is in direct contact with the power supply, safety should be paid attention to. Before using the machine, the following points should be paid attention:

1. Before using, first check whether the power supply conforms to the input voltage specified by the motor.

2. For safety reasons, the three-core power cord with grounding wire must be used to specify Green/ one yellow double color is the ground wire, and the contact and insulation of the wire inside the machine should be checked regularly.

3. When using in wet places, you should wear rubber shoes and insulated gloves.

4. When cleaning or using, do not flow oil into the electrical parts.

5. After the electric brush on the motor and the cable sheath are worn, it needs to be replaced in time.

6. Environmental conditions, relative humidity is not greater85%; Places without flammable gases.

7. When the packaging material is conductive, please use it carefully and pay attention to safety.

Sealing Machine maintenance knowledge:

1. When the machine is newly purchased or not used for several days, sewing machine lubricant should be added to all the oil holes. After idling for half a minute, the engine oil can only start to work after it seeps into the parts, so as to refuel at least three times a day in the working class.

2. After each shift, the machine must be cleaned, especially crochet and feeding mechanism parts. When the machine is cleaning, remove the cover and lift its feet to run for several minutes in the capacity full of diesel oil, then inject the sewing machine oil for several minutes, that is, the cleaning is finished, and the grease in the Helix spindle seat is changed every three months.

3. After the motor electric brush is worn out, replace it in time.

4. When not in use, please place the machine in a dry and ventilated place and cover it with cloth.

TOP

Items have been added to the Inquiry Basket

There are items in the inquiry basket