X Email Mobile

|

|

¥0.0 | 5240 only available |

|

| kerosene silver | ¥0.0 | 5240 only available |

|

| kerosene pink | ¥0.0 | 5240 only available |

|

| kerosene blue | ¥0.0 | 5240 only available |

|

| kerosene green | ¥0.0 | 5240 only available |

|

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

YiWu Magic Digital Imaging Co.,Ltd 5yr.

Main Products:Heat transfer products

Contacts:ZhengtiantianChat

Mobile:86-13735792737

Address:24203 A, 4 Street, 2 F, 51 Gate, International Trade Mart (District 3).

Related items

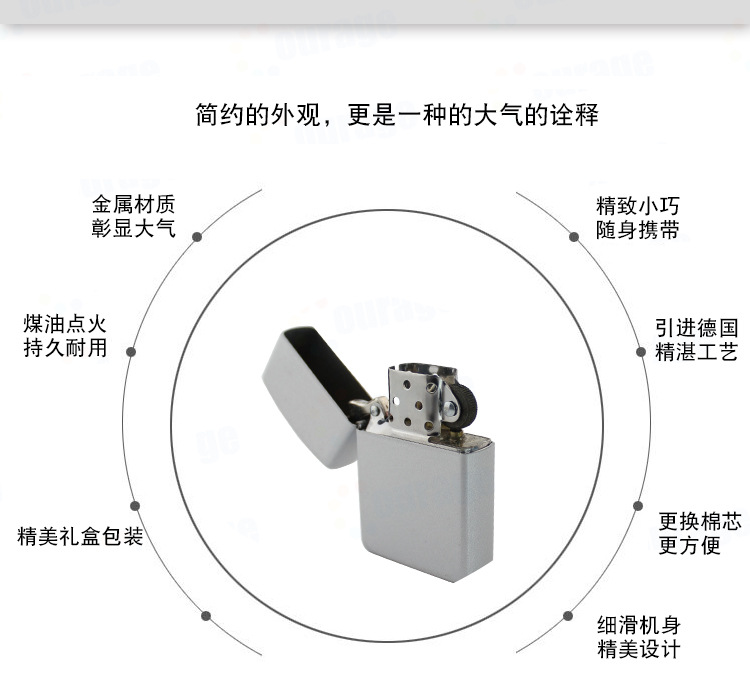

Product Name: Heat Transfer Lighter

Material: Metal

Printing area: 5.8*3.7cm

Packing: Metal Box + White Box

Quantity: 10 per box

Kerosene DIY personalized lighter, iron box packaging with kerosene, double-sided transfer, extremely personalized.

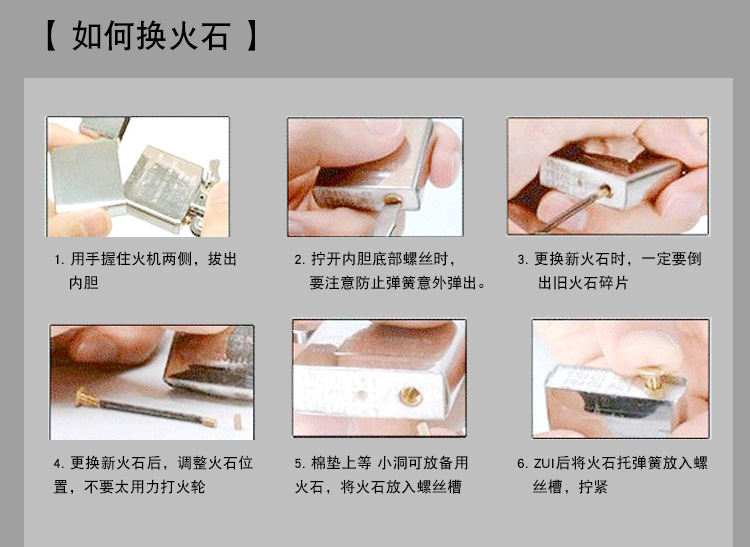

This method is for reference only. It was introduced by a customer who has experienced multiple failures and summarized a more successful method with a higher success rate. We have also operated according to this method, and the results are satisfactory.

Transfer Method(The layer has been improved, with shorter time and better printing results)

If you want to print both sides of the lighter, divide it into sides A and B: 1. First, apply the printed pattern to sides A and B using high-temperature tape and place it in the heat transfer machine for printing (temperature: 180 degrees, time: 100 seconds). Place the A side facing the heating plate and the B side facing down.Silicone padStep 2: After heating, take out a lighter. Do not remove the pattern paper. Flip the B side over the heating plate, with the A side facing down on the silicone pad. Heat again for 100 seconds at 180 degrees. After heating, take out the lighter and remove the drawing paper. The heating imprint is complete.The temperature introduced in this method is in Celsius. If you are working with a machine that uses Fahrenheit, please consider using an initial temperature of 320.Transferred temperature 320, time 100 seconds.)

It is recommended to use sublimation paper to print lighter, and if there is a little bit of adhesive paper when printing, you should reduce the temperature and time appropriately. You can remove it by lightly wiping with water. When printing, the mechanism does not need to be removed. After printing, you can remove the mechanism and add oil from the bottom directly.

Update time:

TOP