X Email Mobile

| EXW Price: |

The price for this item is to be negotiated. Please contact supplier for further information.

|

| Main Products: |

Precision hydraulic cutting machine,automatic cutting machine,plastic cutting machine,blanking machine,automotive interior automatic cutting machine and other industry equipment |

| Contacts: | 陈功Chat |

| Mobile: | 86-13140847121 |

| E-mail: | 455816413@qq.com |

| WeChat: | hg13923483498 |

| Address: | 20575 , 2 F, Yiwu Production Material Market. |

| Address: | 2 Phoenix Avenue, core area of the national Eco-industrial park zone, Danzao town, Nanhai District, Foshan, Guangdong province,Nanhai District,Foshan City,Guangdong Province |

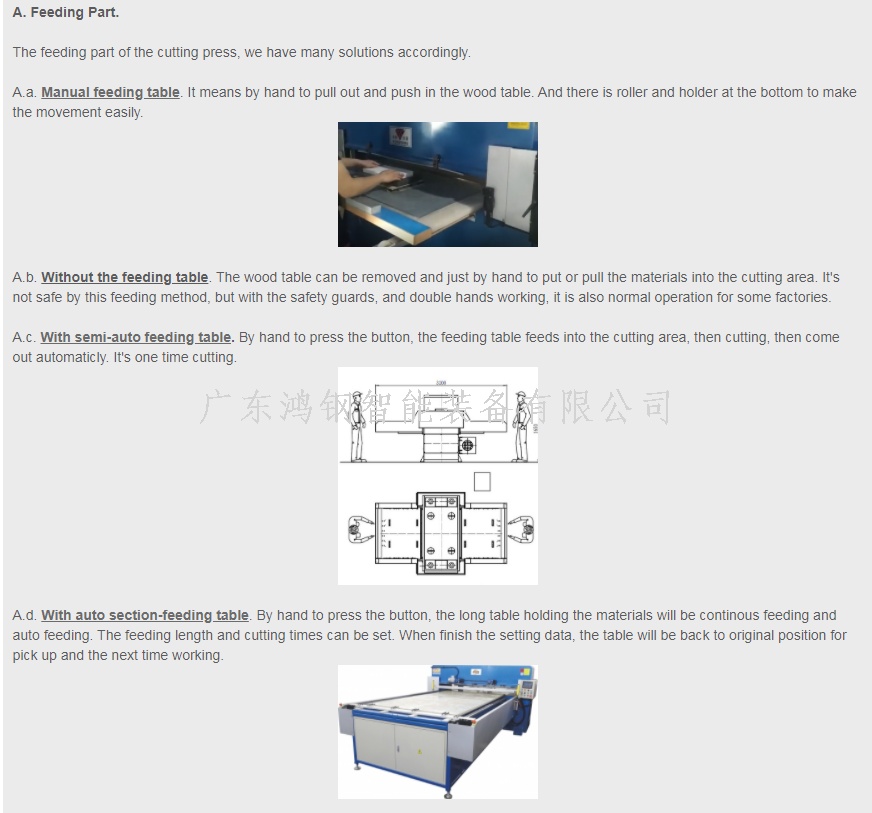

Compared with ordinary manual cutting bed, this manual sliding table still pulls out and pushes feeding machine by hand.

The difference is the feeding table.

1) feeding table.

The ordinary feeding table is made of plywood with wooden handle and push and pull. The wooden table is not fixed on the bracket under the table, but on the roller of the bracket. It is simple and low-cost enough to meet most manual types of work with standard table sizes, such as standard working areas 1220 x610mm,1600 x610mm, or even 1800 x910mm......

New metal workbench and metal bracket with rubber roller. The Workbench is fixed on the roller. This change has many benefits when the Workbench is not removed too much from the cutting area. Moreover, when it is a large table, it is easier to handle, push and pull, and it is also convenient to pick up cutting disc after cutting.

2)PLC control.

The PLC installed on the manual die-cutting machine is not necessary but optional, but it can help make more accurate cutting.

It is also very simple to control the cutting depth and mold setting through the limit switch when the ordinary manual sliding bed is used. However, when using PLC, both the mold setting process and the cutting depth can be controlled by PLC. Only the cutting depth needs to be input to find out the appropriate cutting pressure more accurately and protect cutting knife.

3) press and hold the button to work.

Although there is light sensor protection, it is also a necessary condition for safety to press the button with two hands to lower the cutting head and complete the cutting.

TOP

Items have been added to the Inquiry Basket

There are items in the inquiry basket