X Email Mobile

| Number | Unit-price | Total | |||

| I want to buy: | × | 0.2 | = | 0 |

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

Shantou Chenghai Zhenhuahong Silicone Rubber Products Co., Ltd 3yr.

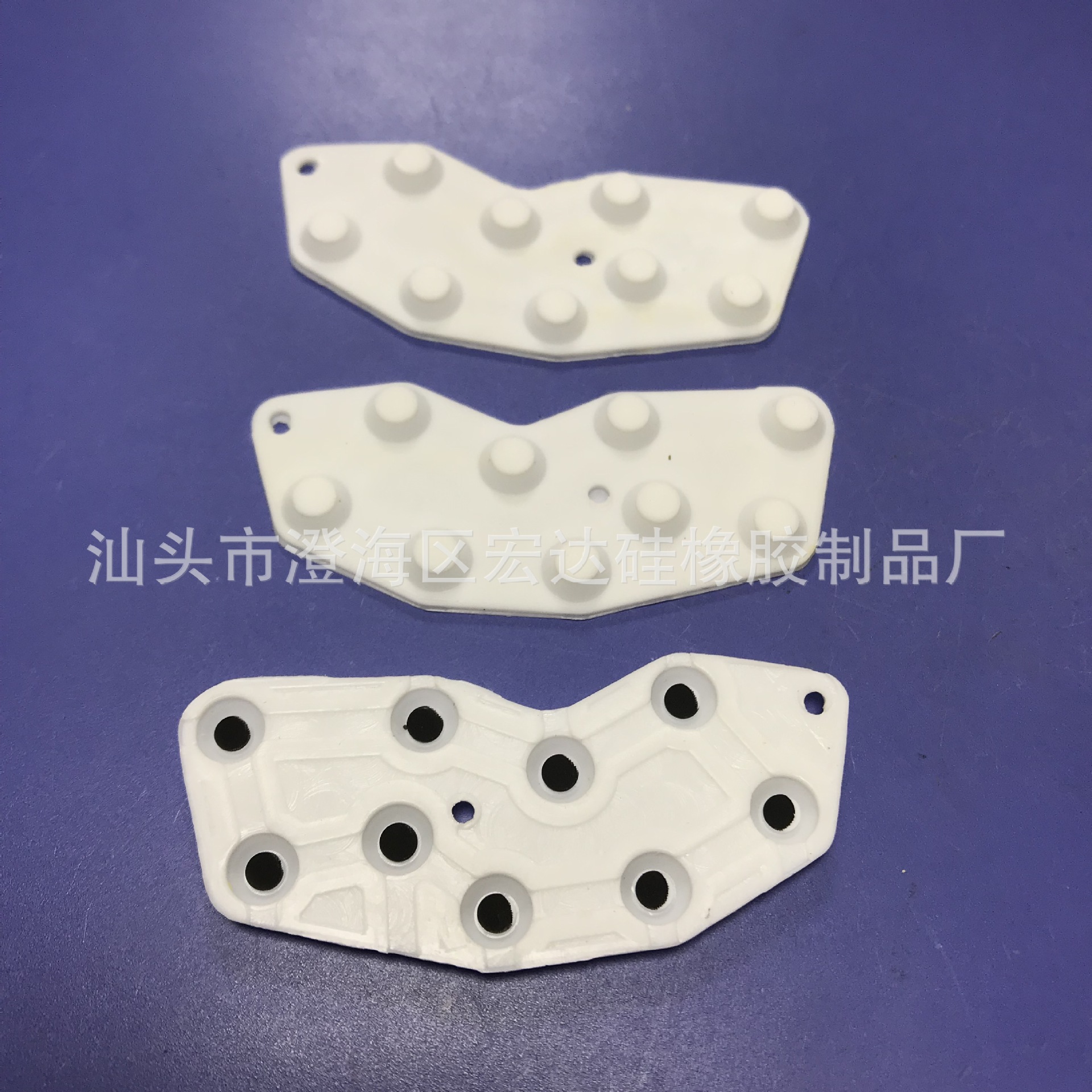

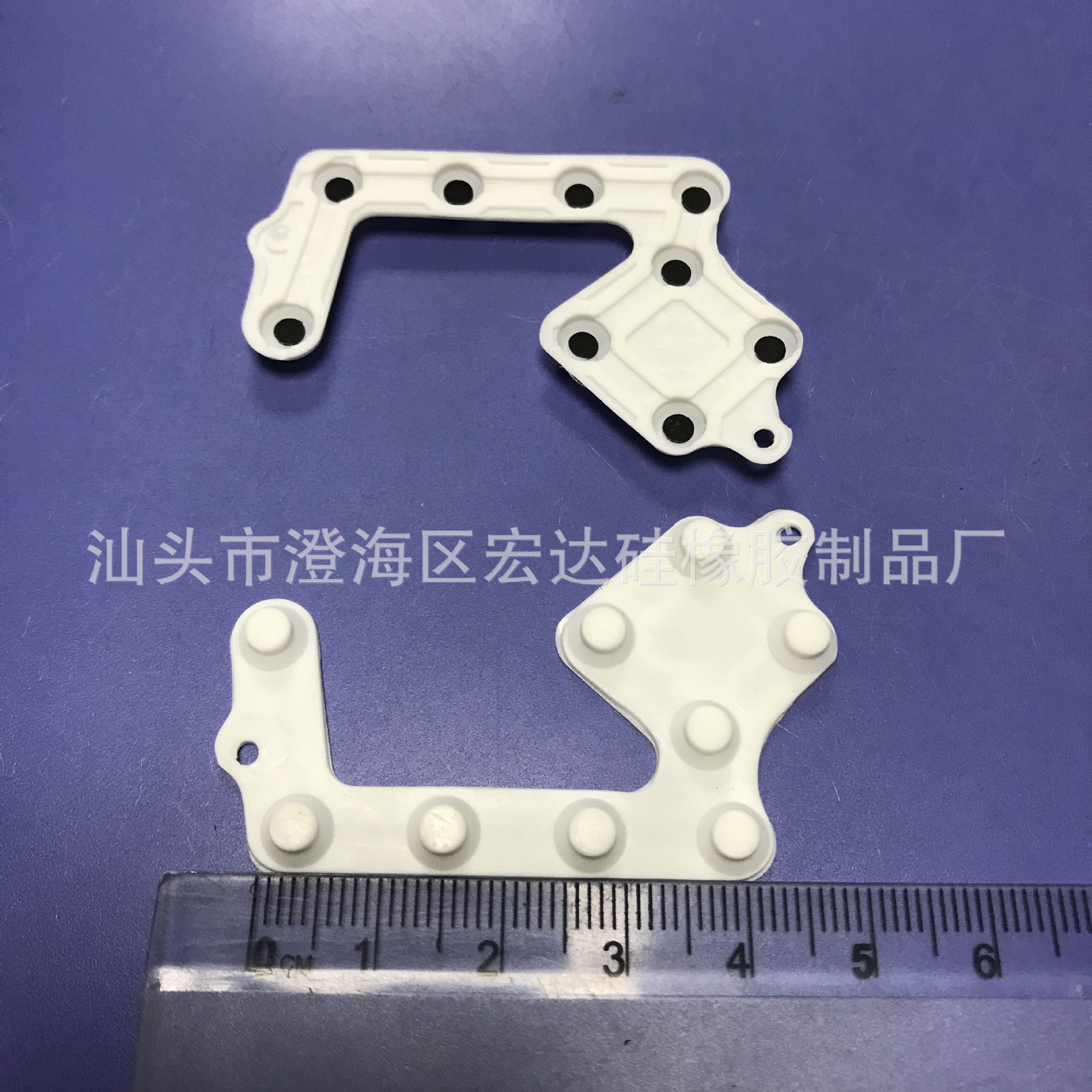

Main Products:Silicone buttons,silicone,toy accessories,silicone rubber products,silicone toys

Contacts:Zeng Li'anChat

Mobile:86-18675401456

E-mail: Address:广东省 汕头 澄海区 澄华街道岭亭工业区长荣二路18号三楼,Chenghai District,Shantou City,Guangdong Province

Related items

![ZZ@57L3RMY8FTX]V5KWV4ID](https://cbu01.alicdn.com/img/ibank/2016/997/273/2832372799_849112457.jpg)

Support free sample (no shipping fee).

![YE7(F]QED{M~)UQ2%_TEK@J](https://cbu01.alicdn.com/img/ibank/2016/852/303/2828303258_849112457.jpg)

Silicone button production process:

1. Material Preparation (also known as rubber mixing, raw material preparation, etc.): This includes the mixing of raw rubber, the color matching, and the weight calculation of the raw materials.

Section Two: Vulcanization Molding (also known as Oil Pressure Molding): This process involves using high-pressure vulcanization equipment to heat-vulcanize silicone raw materials into a solid state.

III. Silkscreen Printing: Full-sheet silicone buttons (higher efficiency in full-sheet printing) are printed with various function symbols. They can be printed in multiple colors and can be engraved with a laser engraver. After printing, they are baked in an oven to dry the ink, ensuring that the color does not fade, making them more durable and wear-resistant.

Fourthly, the process of trimming (also known as processing or deburring) involves removing any useless burrs or shavings after the full-sheet printing is completed. In the industry, this step is entirely manual, although some factories also use a punching machine to complete the task.

V. Surface Treatment: Surface treatment includes using a gas gun to remove dust and adhered impurities.

Section 6: Injection of Oil: Silicone products are easily susceptible to absorbing dust from the air and have a certain degree of stickiness in their ordinary state. By spraying a thin layer of tactile oil on the surface, it can prevent dust and ensure the tactile feel, followed by a second baking after the oil is applied.

7. Other: Other processes include additional functions given to silicone buttons by merchants, such as drop casting, laser engraving, P+R synthesis, optimization of packaging, and assembly with other materials and components.![E]JI2Q9Z_7EIWS)2~7A[`{V](https://cbu01.alicdn.com/img/ibank/2016/179/476/2817674971_849112457.jpg)

Update time:

TOP