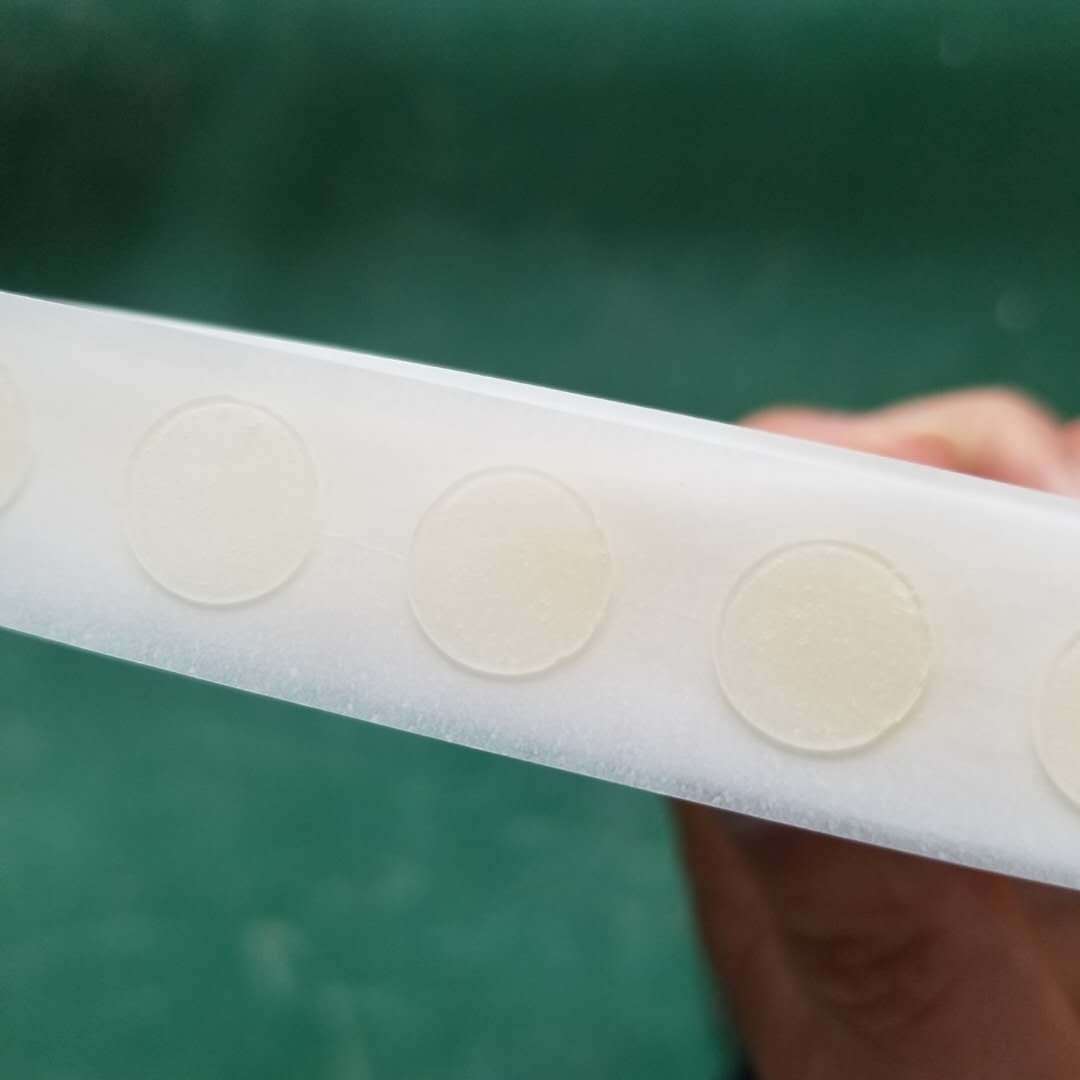

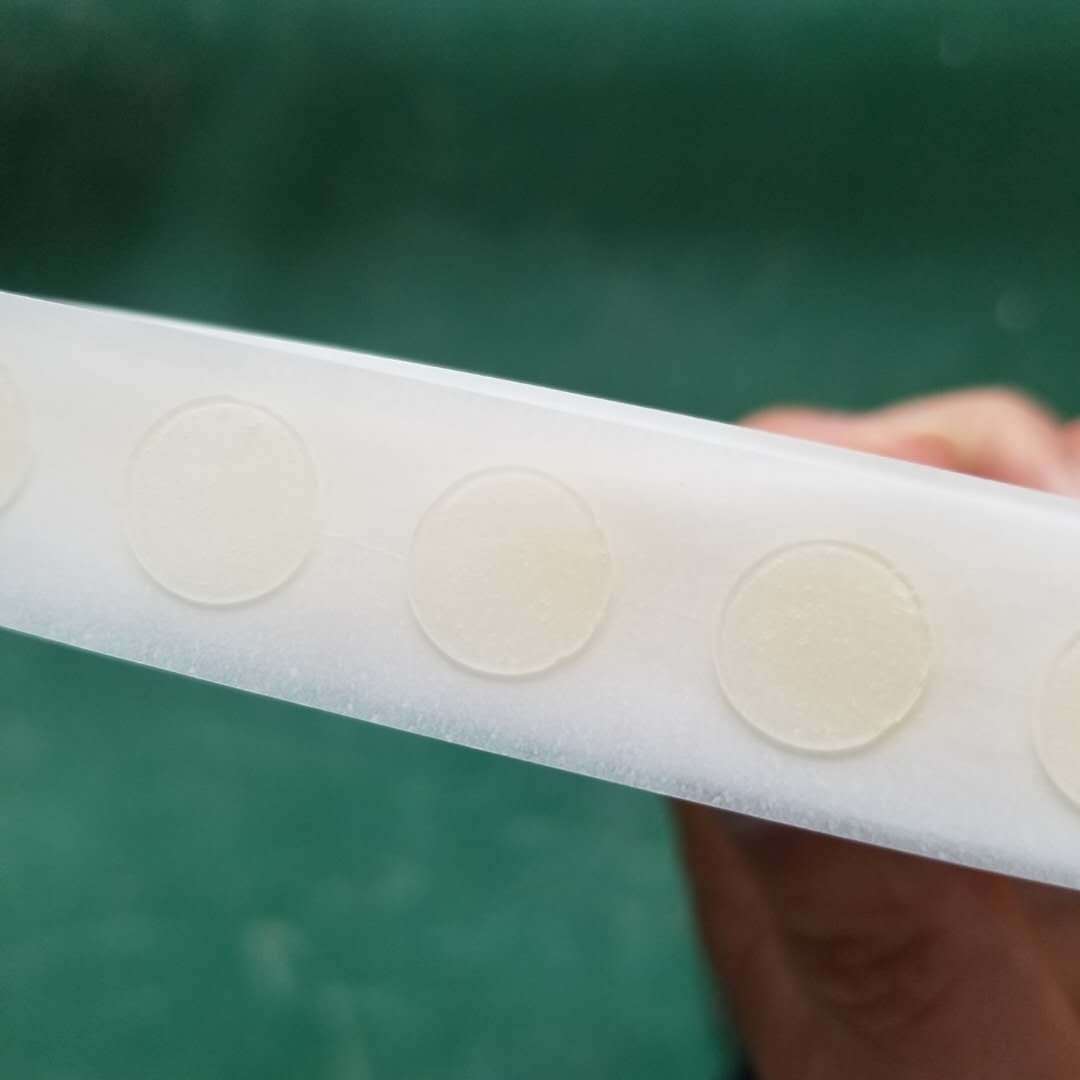

Dot adhesive, also known as removable glue, solid dot adhesive, dot adhesive, grain adhesive, bean adhesive, nasal adhesive, positioning adhesive, invisible removable adhesive, invisible adhesive, industrial adhesive, universal adhesive, PSA adhesive, strong adhesive, c-arft glue art adhesive, is a pre-formed small adhesive dot, ultra-thin adhesive dot, elastic adhesive dot and movable adhesive water dot, can be double-sided adhesive transparent adhesive tape.

The performance of dot matrix adhesive

Transparent color. Ready to use immediately. No trace of movement. Does not damage the surface. And after separation, there will be no residual glue on the adhesive object, and it will not damage the surface of the adhesive object. It is more useful, safer, and more convenient than traditional double-sided tape, and it is more environmental-friendly. It can be used for mass production of products. It is faster and safer than hot melt adhesive! Cleaner and more efficient than liquid adhesives! Unlike traditional double-sided tape, it will not leave residuals! Transparent color! Ready to use! Adhesive! Easy to use! Non-toxic! No equipment needed! Keep clean and can be pasted multiple times! Move at will! No trace left! No damage to the surface! Faster and more convenient than glue! Dot adhesive is suitable for a variety of materials including base materials: paper, cloth, wood, sponge, cedar, glass, glue, metal materials, plastic, polystyrene foam, and many other materials.

The performance of dot matrix adhesive

Paper packaging, paper card and PVC film positioning, fixed instructions for booklets and magazines, PET adhesion, printing start-up, printing decoration (including DVD discs), food packaging (such as wine boxes/candy packaging), greeting card production, notebooks, craft production, toy gifts, maintaining the upright position of candles, bathroom products and support fixation and bonding, small household appliances packaging, direct mailing and promotion, product exhibitions, signs, amateur production, various activities for families, schools, and offices, and the fixation and packaging of fragile and liquid products, as well as electronic product packaging industries. For factories that assemble large products, not only does it save working hours, but it also enhances the packaging image of the product, improving the company's visibility.

How to Choose the Appropriate Specifications:

1) Size: Match the size of the adhesive dots to the size of the object;

2) Thickness: It depends on the weight of the object, the contact surface, thickness, and hardness; low thickness is usually used for flat substrates; medium and high thicknesses are suitable for adhesive application on circular and irregular shaped substrates.

III) Viscosity: a) According to the smoothness of the object surface; b) Flat or with concave and convex surfaces; c) The degree of "no trace" required when the two objects are separated or whether permanent adhesion is needed.

The standard specifications and dimensions of removable adhesive spots:

1) Size: Round/Square/Rectangular/Striped, with diameters ranging from 5mm to 20mm per grain;

Two)、Thickness: from 0.2mm-2.0mm;

(3) Viscosity: Low/Medium/High.

Four)、Packing: Roll/Sheet;

five)、Customized sizes can be made according to customer requirements.

The use method of the adhesive dots:

Please be advised: Do not remove the adhesive drop with your fingers directly.

1. This product should not come into contact with oil or dust, as they may affect the adhesive properties and adhesion of the product. The surface to be bonded must be clean and dry, and it must be cleaned before using the adhesive.

2. When operating, avoid contact between your fingers and the adhesive surface. You must place the object directly on the "adhesive point" surface and press lightly. Immediately transfer it to the object, and it can be pasted onto another object. After pasting, you must press firmly to ensure full contact between the adhesive surface and the pasting surface, and no air residuals, so that the pasting effect is better.

3. Thicknesses lower than average are typically used for flat substrates; medium and higher thicknesses are suitable for adhesive applications on circular and irregular shaped substrates.

Wan Shuo