X Email Mobile

| EXW Price: |

|

|

REEDRLON 6yr. |

|

| Main Products: |

Barbed wire,wire,galvanized wire,black wire,nails,hexagonal network,electric welding network,Dutch network,fence network,sugar cane knife |

| Contacts: | BillChat |

| Mobile: | 86-13735649879 |

| WhatsApp: | 008613588687685 |

| E-mail: | 823782366@qq.com |

| WeChat: | 008613735649879 |

| Address: | 13337 B, 2 Street, 2 F, 23 Gate, International Trade Mart (District 2). |

| Address: | Liusu Industrial,Dingzhou city, Hebei Province |

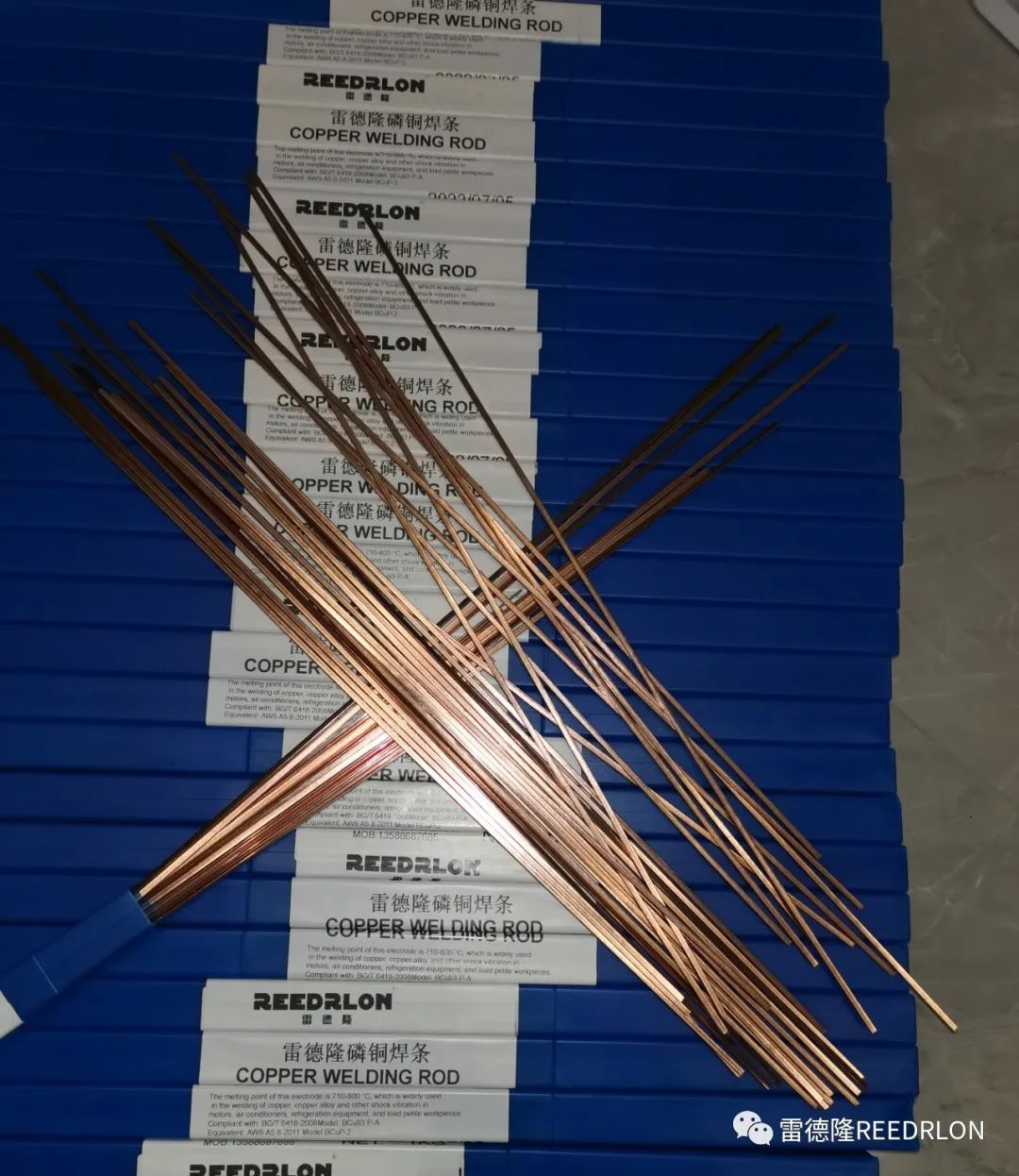

thickness ( thickness):1.3mm

length ( Length):400mm 500mm

packaging ( Packing):1kg/box

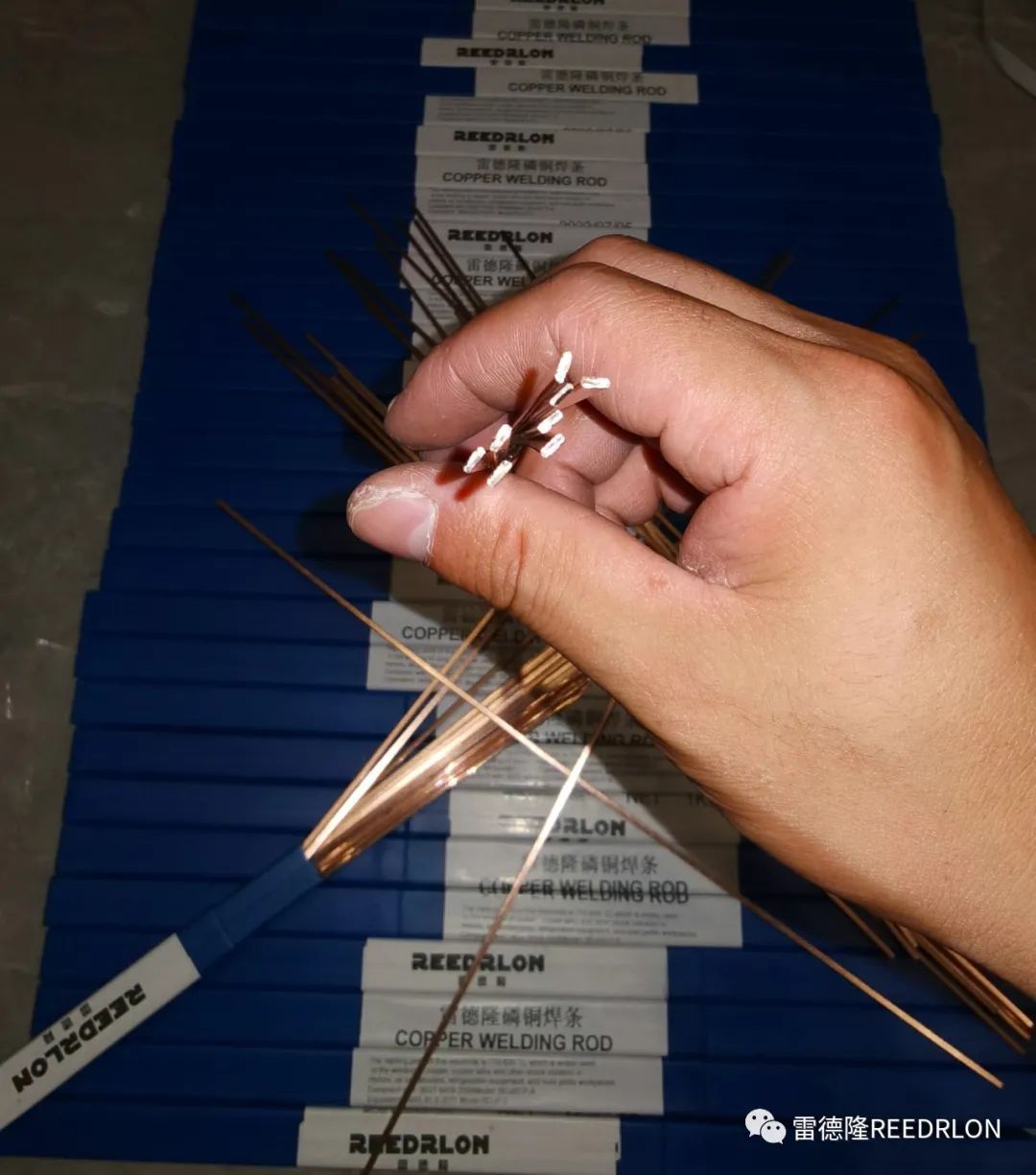

welding of copper and copper pipe connector for refrigeration systems of air conditioners, freezers and refrigerators

phosphor bronze welding rod, suitable for welding copper and copper pipe connector in refrigeration systems of air conditioners, freezers and refrigerators.

Used for welding of copper and copper pipe joints in refrigeration system of air conditioner, freezer and refrigerator

Phosphor COPPER electrode, suitable for the welding of copper and copper pipe joints in the refrigeration system of air conditioner, freezer and refrigerator.

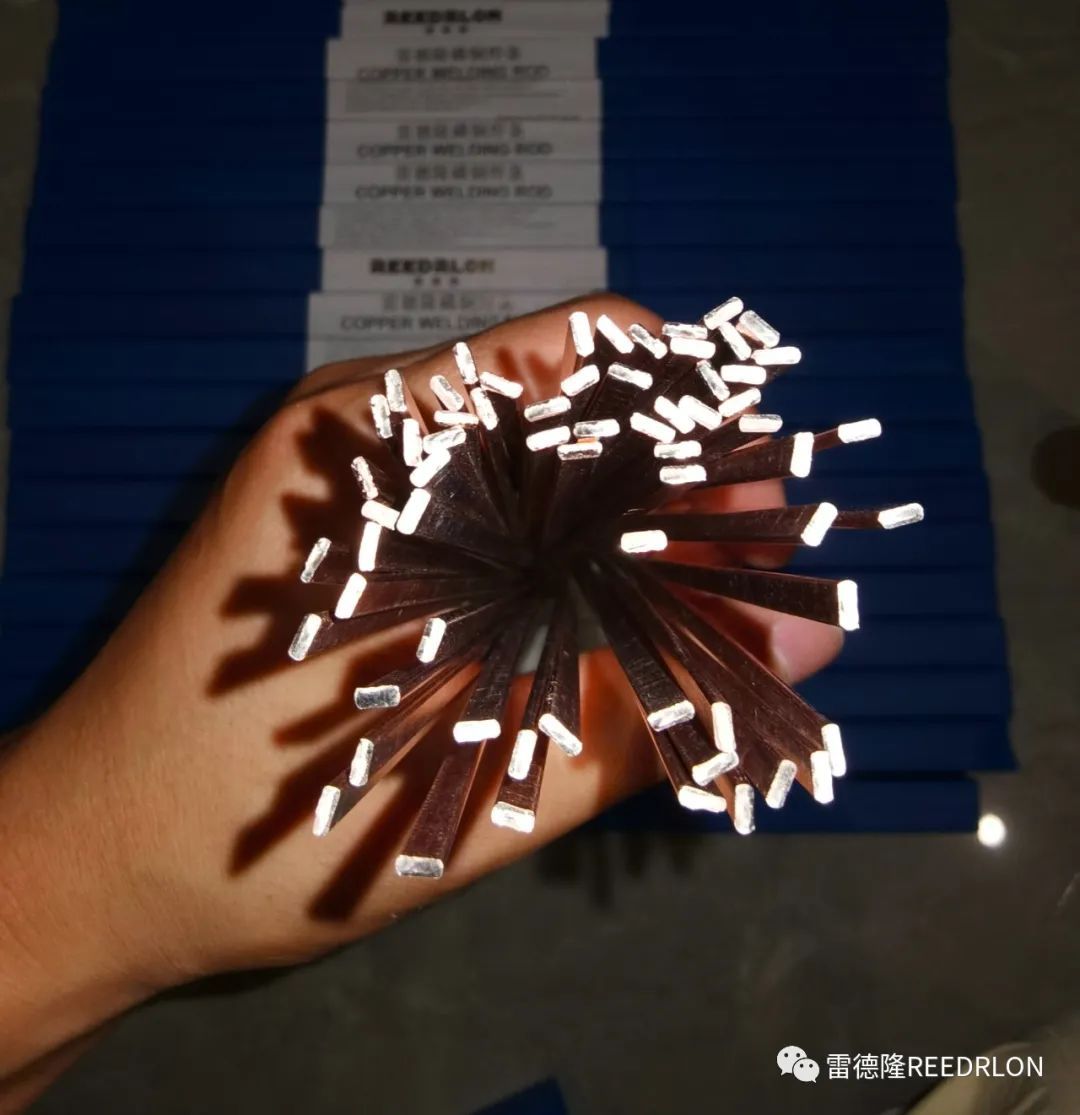

Chinese name: phosphor bronze welding rod

chemical composition: P:6.8-7.2

use way: air conditioner, freezer

sex energy: low melting point and good liquidity

Chinese name

Phosphor copper electrode

Chemical composition

P: 6.8 to 7.2

With the way

Air conditioner, freezer

Sex can

Low melting point and good fluidity

edit broadcast

phosphor bronze welding rod: BCU93P, BCU91PAG

main, Cu: margin

edit broadcast

brazing temperature710-810 ℃, low melting point, good liquidity, low cost, silver cutting, silver replacing.

edit broadcast

1, BCu92P: Ingredients P:7.5-8.5%, copper: margin. Melting temperature710-750℃, with low melting point, the solder has good fluidity but is relatively brittle, which is generally used for welding copper and brass parts without impact load and vibration;

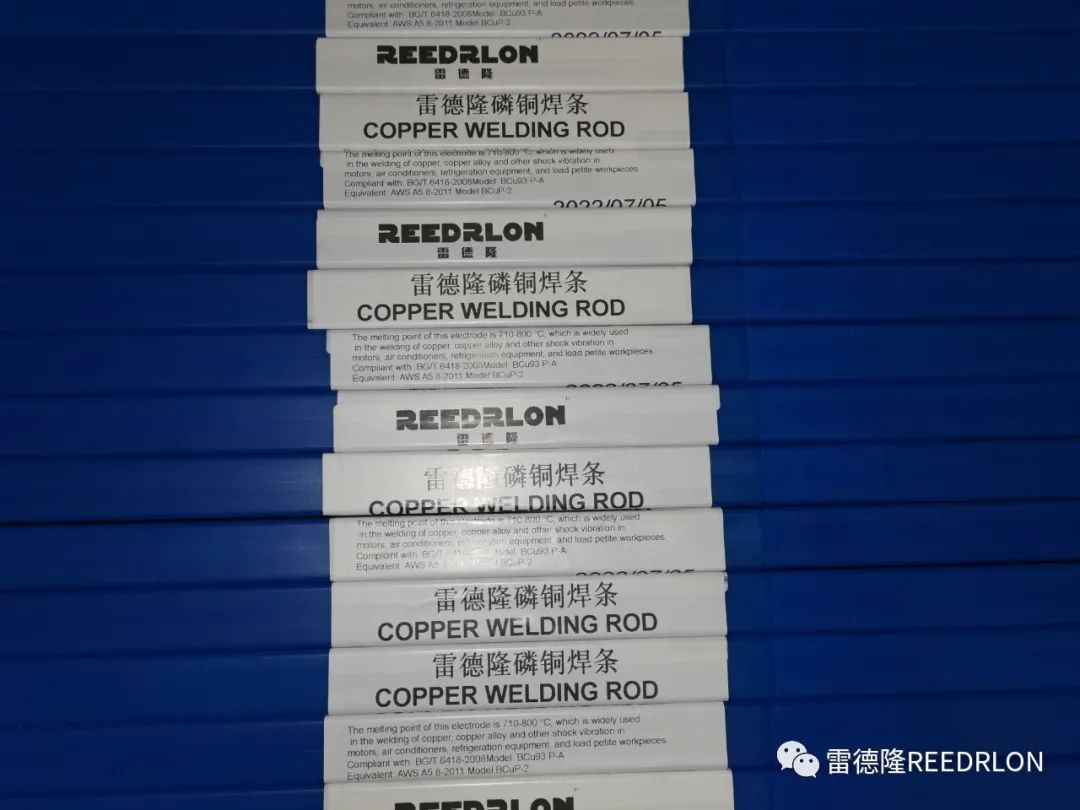

2, BCu93P( HL201/BCuP-2): Ingredients P:6.80-7.50%, copper: margin. Melting temperature710-793 ℃, the solder has good fluidity and can flow into joints with small gap, but it is brazing material brittle. It is generally used in electromechanical and instrument industries and brazes copper and brass parts that are not subject to impact load;

3, BCu89SnP( HL208): Ingredients P:6.80-7.50%, tin:5.0-6.0%, copper: margin. Melting temperature620-660 ℃, the solder has low melting point and good fluidity, and can be used with silver brazing agent to brazing copper, brass, bronze and low zinc brass parts;

4, BCu86SnP: Ingredients P:4.80-5.80%, tin:7.00-8.00%, Nickel:0.40-1.20%, copper: margin. Melting temperature620-670 ℃, the use of this solder is the same as above. The addition of nickel increases brittleness, but improves fluidity, and the weld is bright. It is generally used for brazing copper and brass.

5, BCu91AgP( HL209/BCuP-6): Ingredients P:5.50-7.50%, Silver1.80-2.20%, copper: margin. Melting temperature645-771 ℃, low melting point, the solder can fill the joint gap in a large temperature range, and is mostly used for brazing copper and brass pieces in industries such as refrigerators, air conditioners, motors and instrument banks;

6, BCu89AgP( BCuP-3): Ingredients P:5.8-6.70%, Silver4.80-5.20%, copper: margin. Melting temperature645-788 ℃, with low melting point, the ductility and conductivity of the solder are improved, and the fluidity is general, which is suitable for copper and brass parts with large brazing gap;

7, BCu88AgP( HL205/BCuP-7): Ingredients P:6.50-7.00%, Silver4.80-5.20%, copper: margin. Melting temperature645-780 ℃, the melting point is low, the ductility and conductivity of the solder are improved, and the fluidity is better B- Cu89PAg, generally used for brazing copper and brass parts with large gap;

8, BCu87PAg( BCuP-4): Ingredients P:7.0-7.5%, Silver5.80-6.20%, copper: margin. Melting temperature645-718 ℃, low melting point, the solder has low melting point, good fluidity, can solder joints with small gap, and is generally used for brazing copper and brass parts;

9, BCu80PAg( HL204/BCuP-5): Ingredients P:4.80-5.30%, Silver14.50-15.50%, copper: margin. Melting temperature645-815 ℃, the melting point is low, and the ductility and conductivity of the solder are further improved, which is used for welding requirement ratio HL205(5% silver) copper and brass parts with brazing material high and large joint gap.

10, BCu60ZnSn- R(S221/RBCuZn- A): component copper:59.00-61.00%, tin0.80-1.20%, Silicon:0.15-0.35%, zinc: margin. Melting temperature890-905 ℃, the solder has a high melting point and can be used for welding carbide-tipped tool, molds and mining tools. And can be replaced H62 solder to obtain relatively dense weld, and can be used as welding wire for gas welding brass

Introduction to

Editors broadcast

Phosphor copper electrode: BCU93P, BCU91PAG

Main,Cu: allowance

Performance of phosphor copper electrode

Editors broadcast

Brazing temperature 710-810℃, low melting point, good fluidity, low cost, silver saving, silver substitute.

Classification and Composition

Editors broadcast

1, BCu92P: composition P: 7.5-8.5%, copper: allowance. Melting temperature 710-750℃, low melting point, the solder fluidity is good, but relatively brittle, generally used for brazing without impact load, vibration of copper and brass parts welding;

2, BCu93P (HL201/ BCUP-2) : composition P: 6.80-7.50%, copper: allowance. Melting temperature 710-793℃, the solder fluidity is good, can flow into the joint with small gap, but the solder is brittle, generally used in mechanical and electrical and instrument industry, brazing copper and brass parts without impact load;

3, BCu89SnP (HL208) : composition P: 6.80-7.50%, tin: 5.0-6.0%, copper: allowance. The melting temperature is 620-660℃. The solder has low melting point and good fluidity. It can braze copper, brass, bronze and low zinc brass parts with silver brazing agent.

4, BCu86SnP: composition P: 4.80-5.80%, tin: 7.00-8.00%, nickel: 0.40-1.20%, copper: allowance. Melting temperature 620-670℃, the use of the solder is the same as above, the addition of nickel makes brittleness increase, but the fluidity is improved, and the weld is bright, generally used for copper and brass brazing.

5, BCu91AgP (HL209/ BCUP-6) : Composition P: 5.50-7.50%, silver 1.80-2.20%, copper: allowance. Melting temperature 645-771℃, low melting point, the solder can fill the joint gap in a wide range of temperature, mostly used in refrigerators, air conditioners, motors and instruments and other industries brazing copper and brass parts;

6, BCu89AgP (BCUP-3) : composition P: 5.8-6.70%, silver 4.80-5.20%, copper: allowance. The melting temperature is 645-788℃, the melting point is low, the ductility and conductivity of the solder are improved, the fluidity is general, and it is suitable for copper and brass parts with large brazing gap;

7, BCu88AgP (HL205/ BCUP-7) : Composition P: 6.50-7.00%, silver 4.80-5.20%, copper: allowance. The melting temperature is 645-780℃, the melting point is low, the ductility and conductivity of the solder are improved, the fluidity is better than B- Cu89PAG, generally used for brazing copper and brass parts with large gap;

8, BCu87PAg (BCUP-4) : Composition P: 7.0-7.5%, silver 5.80-6.20%, copper: allowance. Melting temperature 645-718℃, low melting point, the solder melting point is low, fluidity is good, can braze the joint with small gap, generally used for brazing copper and brass parts;

9, BCu80PAg (HL204/ BCUP-5) : composition P: 4.80-5.30%, silver 14.50-15.50%, copper: allowance. With a melting temperature of 645-815℃ and a low melting point, the ductility and electrical conductivity of the solder are further improved, and it is used for welding copper and brass parts with higher joint gap than HL205 (5% silver) filler metal.

10, BCU60ZNS- R (S221/ RBCuZN- A) : Copper: 59.00-61.00%, tin 0.80-1.20%, silicon: 0.15-0.35%, zinc: allowance. The melting temperature is 890 ℃ to 905℃, the solder melting point is high, can be used for hard alloy tool, die and mining tools welding. And can replace the H62 solder to obtain a relatively dense weld, and can be used as gas welding brass wire

A large number of stock supply! Looking forward to cooperating with you!

A large number of spot supply! Looking forward to cooperating with you!

Believe in professional power!

We are serious about making welding rods!

Please select Redlon!

Redlon goes with you!!!

Believe in professional power!

We are serious about making welding rod!

Good welding rod, please choose REEDRLON!

REEDRLON with you toghter! ! !

TOP

Items have been added to the Inquiry Basket

There are items in the inquiry basket