X Email Mobile

A new item has been added to your Shopping Cart. You now have items in your Shopping Cart.

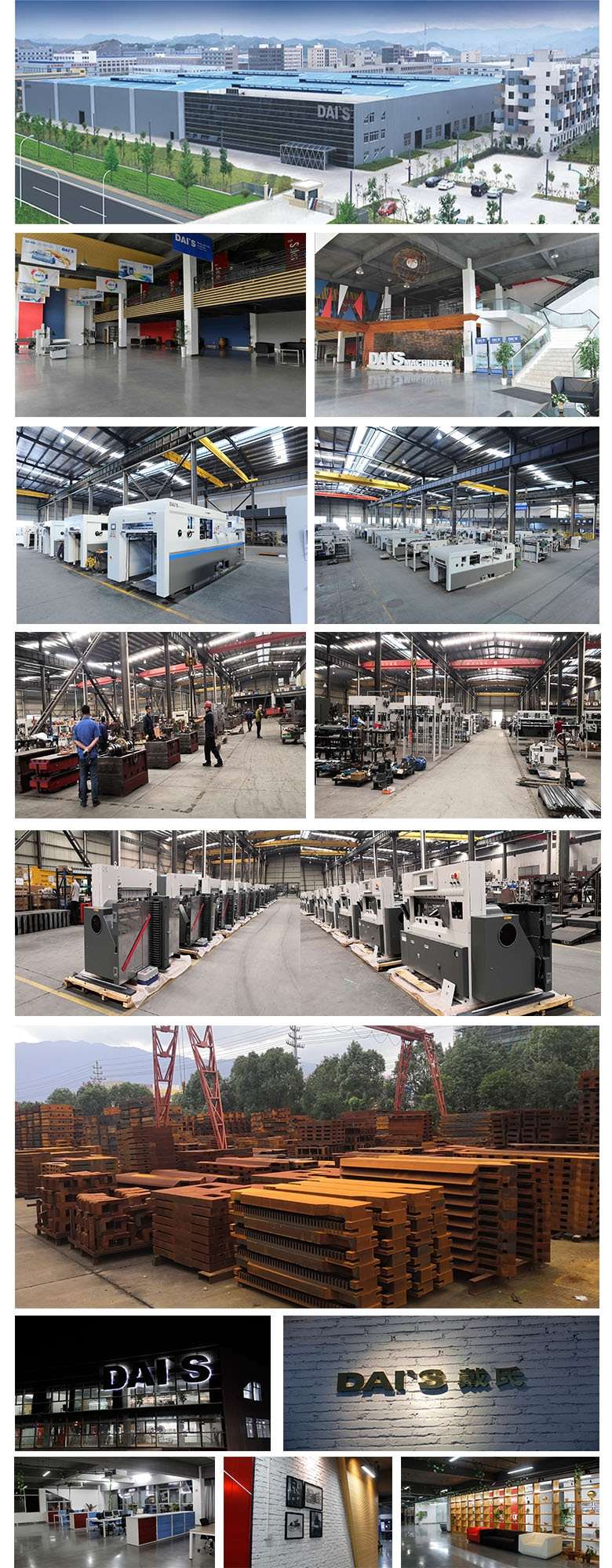

yiwu taii Printing Machinery Co., Ltd. 11yr.

Main Products:Printing and cutting machinery

Contacts:Li jun YuChat

Mobile:86-15858930913

Address:20847 , 2 F, Yiwu Production Material Market.

Related items

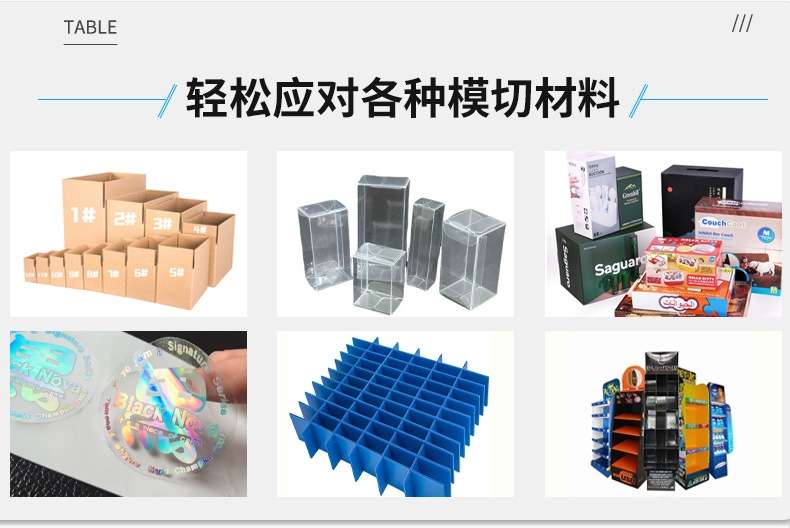

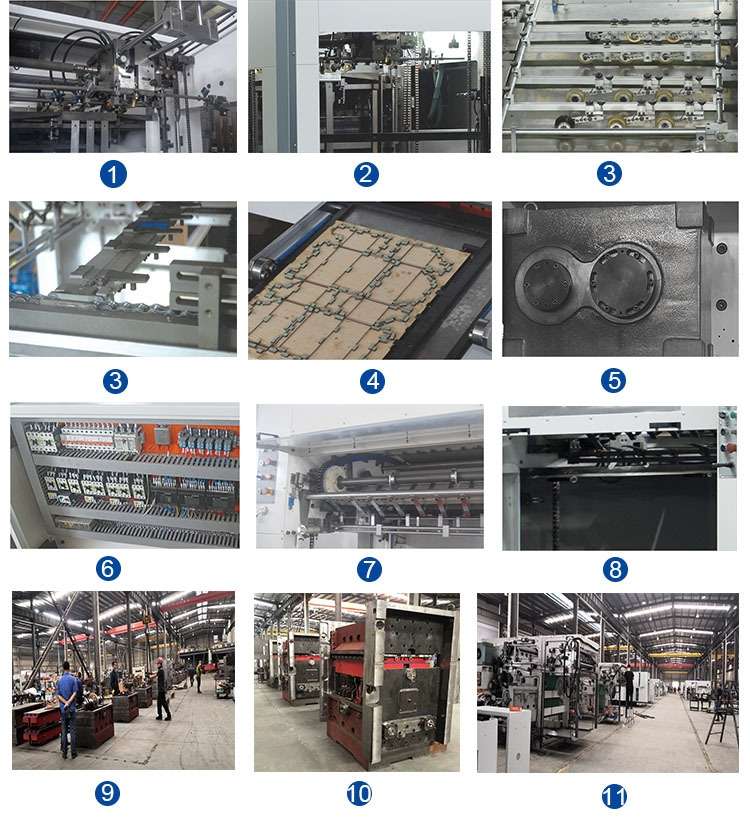

D1060S Automatic Flat-Press Die Cutting and Creasing Machine is a critical equipment for die cutting and creasing of various paper packaging products such as paper boxes, cartons, labels, gift boxes, etc. This machine features a high-precision intermittent mechanism, pneumatic plate lock, pneumatic clutch, and manual pressure adjustment, ensuring high-speed and smooth operation.

The machine uses internationally renowned brand components for its key parts, with all major parts tightly machined by CNC machines. The use of this machine achieves the highest productivity, high safety, and a user-friendly operating interface.

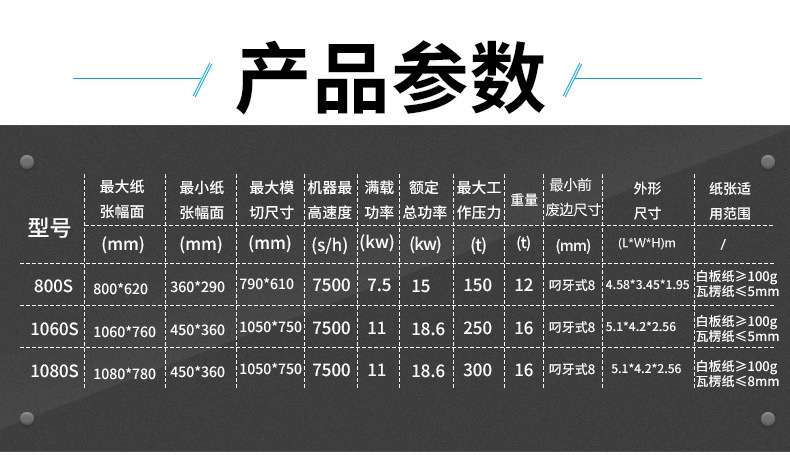

Technical parameters of the die cutting machine:

- Model: D1060S

- Maximum paper size: 1060×760mmMinimum Paper Size (mm) 450×360mm Maximum Cutting Machine Size 1050×750mm Machine's Highest Speed 6000shFull load power: 15kw

Maximum working pressure: 250t

Machine weight: About 17T

Machine appearance: 5800×2100×2300mm without working steps

Model: WLH

Overall dimensions: 6800×4800×2300mm contains work pedal

Paper applicability:

Whiteboard paper ≥ 100 (g), corrugated paper ≤ 4 (mm)

Die cutting knife height:

238MM

Pressure adjustment range:

±1 (mm)

Minimum front waste edge size:

8 (mm) for the clamping type

Maximum size of wood mold:

1080×790 (mm)

Machine configuration:

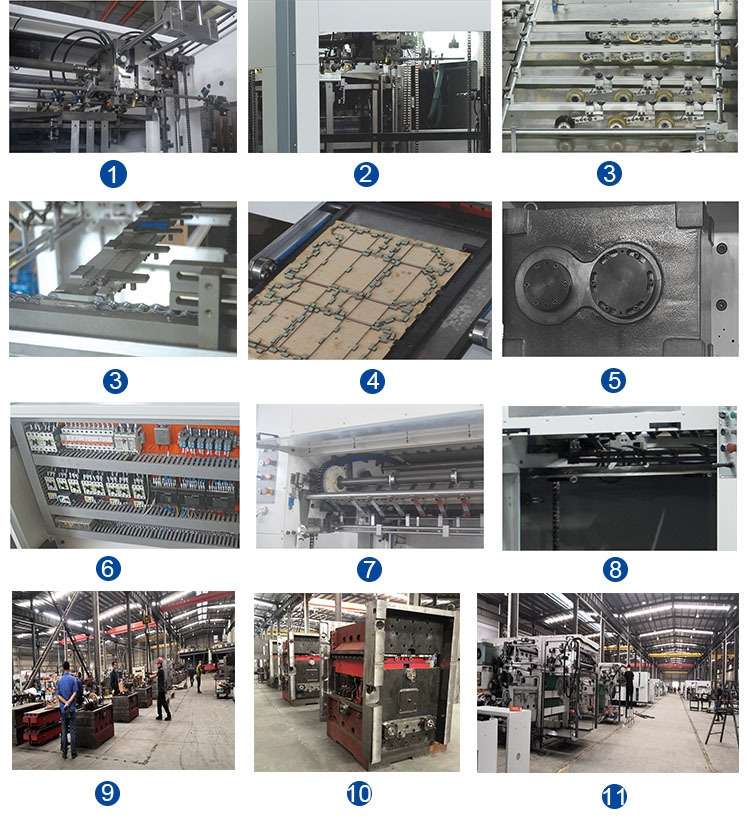

Standard configuration: 1Paper feeding section: Jet-type paper feeding method, vacuum paper conveying platform, feeder head, front and side photoelectric detection, obstacle prevention device, vacuum pump, side guides with push-pull conversion, double-sheet detection, electrically controlled front guide and side guides.

2. Cutting section: with template and press plate pneumatic latch, center line system, high-quality tooth-gripping blades, imported Japanese pre-stretched high-quality chains, electric pressure adjustment, pneumatic clutch system, cutting plate start-up lifting, main drive automatic lubrication and cooling system, chain automatic lubrication system, main motor frequency conversion control.

3. De-waste section with center line system

4. Paper collecting section: non-stop machine paper collection, with rear and lateral positioning, with electric paper collecting brushing.

5. Electrical section: using high-quality electrical components, 104-inch display, 7-inch touch-operated screen (optional charge)

1. Optional imported feeder head

2. Optional pre-stacking device, non-stop paper feeding

3. Optional de-waste preparatory stand

D1060S Automatic Flat-Press Die Cutting and Creasing Machine is a critical equipment for die cutting and creasing of various paper packaging products such as paper boxes, cartons, labels, gift boxes, etc. This machine features a high-precision intermittent mechanism, pneumatic plate lock, pneumatic clutch, and manual pressure adjustment, ensuring high-speed and smooth operation.

The machine uses internationally renowned brand components for its key parts, with all major parts tightly machined by CNC machines. The use of this machine achieves the highest productivity, high safety, and a user-friendly operating interface.

Technical parameters of the die cutting machine:

- Model: D1060S

- Maximum paper size: 1060×760mmMinimum Paper Size (mm) 450×360mm Maximum Cutting Machine Size 1050×750mm Machine's Highest Speed 6000shFull load power: 15kw

Maximum working pressure: 250t

Machine weight: About 17T

Machine appearance: 5800×2100×2300mm without working steps

Model: WLH

Overall dimensions: 6800×4800×2300mm contains work pedal

Paper applicability:

Whiteboard paper ≥ 100 (g), corrugated paper ≤ 4 (mm)

Die cutting knife height:

238MM

Pressure adjustment range:

±1 (mm)

Minimum front waste edge size:

8 (mm) for the clamping type

Maximum size of wood mold:

1080×790 (mm)

Machine configuration:

Standard configuration: 1Paper feeding section: Jet-type paper feeding method, vacuum paper conveying platform, feeder head, front and side photoelectric detection, obstacle prevention device, vacuum pump, side guides with push-pull conversion, double-sheet detection, electrically controlled front guide and side guides.

2. Cutting section: with template and press plate pneumatic latch, center line system, high-quality tooth-gripping blades, imported Japanese pre-stretched high-quality chains, electric pressure adjustment, pneumatic clutch system, cutting plate start-up lifting, main drive automatic lubrication and cooling system, chain automatic lubrication system, main motor frequency conversion control.

3. De-waste section with center line system

4. Paper collecting section: non-stop machine paper collection, with rear and lateral positioning, with electric paper collecting brushing.

5. Electrical section: using high-quality electrical components, 104-inch display, 7-inch touch-operated screen (optional charge)

1. Optional imported feeder head

2. Optional pre-stacking device, non-stop paper feeding

3. Optional de-waste preparatory stand

Update time:

TOP